Fixed bed reactor

A fixed bed reactor and reaction gas technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost, difficult to large-scale, difficult catalyst filling, limited tube sheet space, etc., and achieve reaction temperature control. Uniformity, reducing process air resistance, and large circulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

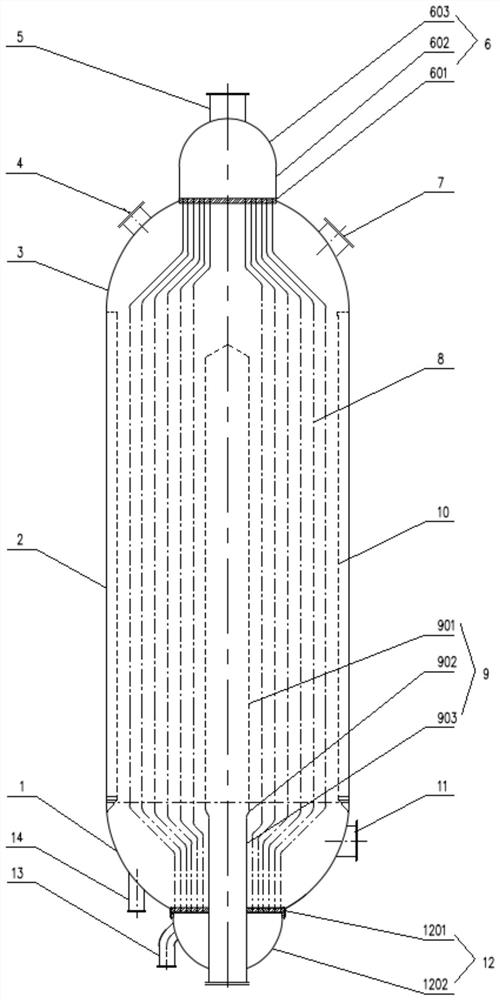

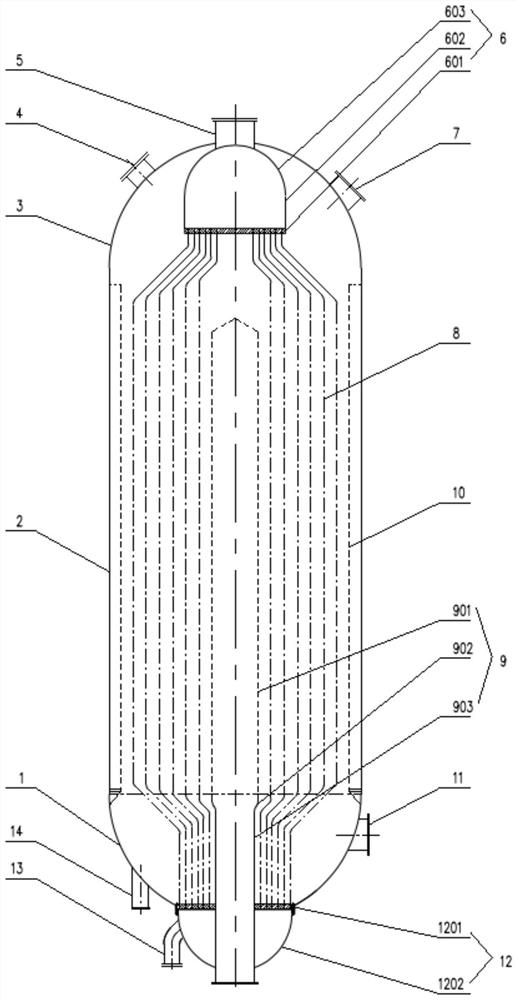

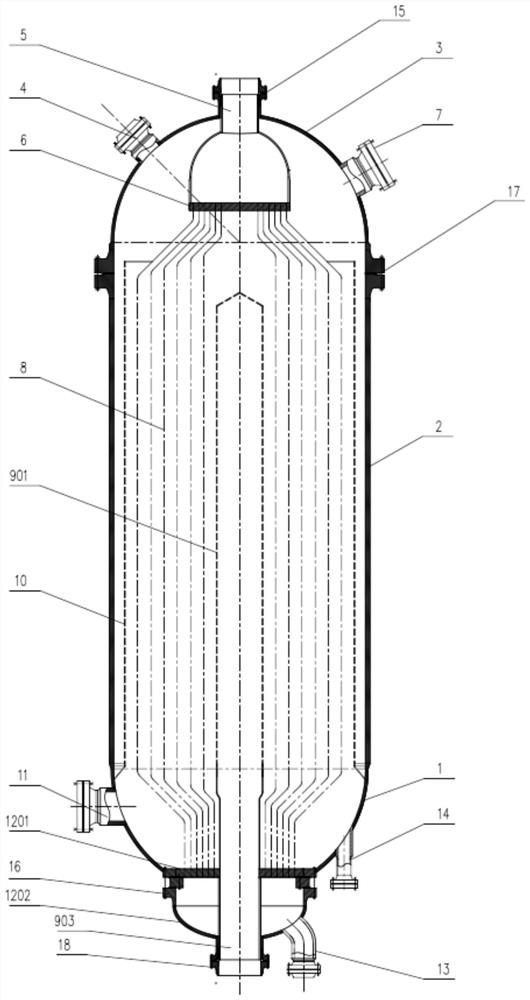

[0024] According to the requirements of GB151 shell and tube heat exchanger, the center distance of heat exchange tubes should not be less than 1.25 times the outer diameter of heat exchange tubes. The center distance of commonly used heat exchange tubes is between 1.25 and 1.3 times the outer diameter of heat exchange tubes. The reactor used for heat transfer and heat transfer needs to be filled with catalyst between the heat exchange tubes, so the distance between the heat exchange tube layers is more than twice the outer diameter of the heat exchange tubes, so the tube sheet with a smaller radial dimension than the shell can be used To arrange the number of heat exchange tubes that meet the heat transfer requirements, and the heat exchange tubes are bent to fill the shell. Another advantage of using a tube sheet smaller than the radial dimension of the shell is that the space outside the tube sheet can be used to arrange the loading and unloading ports of the catalyst and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com