Undok pulverized coal gasification furnace with nitrogen, water vapor and synthesis gas-driven material return mechanism

A technology of gasification furnace and steam, applied in the field of coal chemical industry, can solve the problems of low carbon conversion rate, high specific coal consumption, high content of fly ash combustibles, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

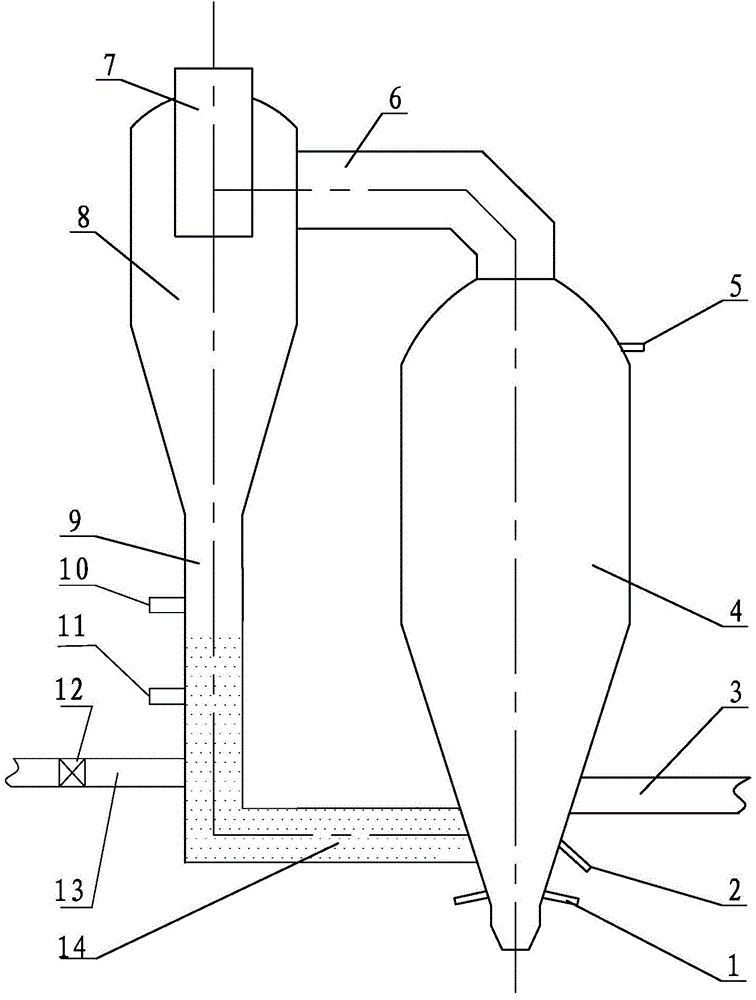

[0012] Specific implementation mode one: combine figure 1 Describe this embodiment. An Ende pulverized coal gasifier with nitrogen, water vapor, and synthesis gas-driven return mechanism described in this embodiment includes a gasifier body 4, a pipeline 6, a cyclone separator 8, and an outlet of the cyclone separator. Vertical feeding channel 9, working gas flow regulating valve 12, working gas pipeline 13 and horizontal feeding channel 14, the middle part of the upper surface of gasification furnace body 4 is connected with the inlet of cyclone separator 8 through pipeline 6, and cyclone separator 8 The top of the top is provided with a gas phase outlet 7, the lower end of the cyclone separator 8 is connected with the upper end of the vertical discharge channel 9 of the cyclone separator outlet, and the lower end of the vertical discharge channel 9 of the cyclone separator outlet is connected with one end of the horizontal discharge channel 14, The other end of the horizonta...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the top of the gasifier body 4 of an Ende pulverized coal gasifier with nitrogen, water vapor, and syngas-driven return mechanism described in this embodiment is provided with a pressure measuring point 5 on the top of the gasifier. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 Describe this embodiment. The outer wall of the vertical feeding channel 9 at the outlet of the ende pulverized coal gasifier with nitrogen, water vapor, and syngas-driven return mechanism described in this embodiment is sequentially arranged from top to bottom. A first material level gauge 10 and a second material level gauge 11 are provided. Other components and connections are the same as those in the first embodiment.

[0017] working principle

[0018] The circulating ash passes through the discharge channel 9 of the cyclone separator, and accumulates ash in the discharge channel 9 and 14 to form a material seal, which isolates the influence of the high pressure at the bottom of the gasifier on the flow field in the cyclone separator, so that the finer particles can also Can fall by gravity. The steam with a steam pressure of about 0.6-1 MPa is drawn from the waste heat boiler into the working gas pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com