Production method and device of needle coke

A production method and needle coke technology are applied in the field of carbon materials to achieve the effect of wide application field and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

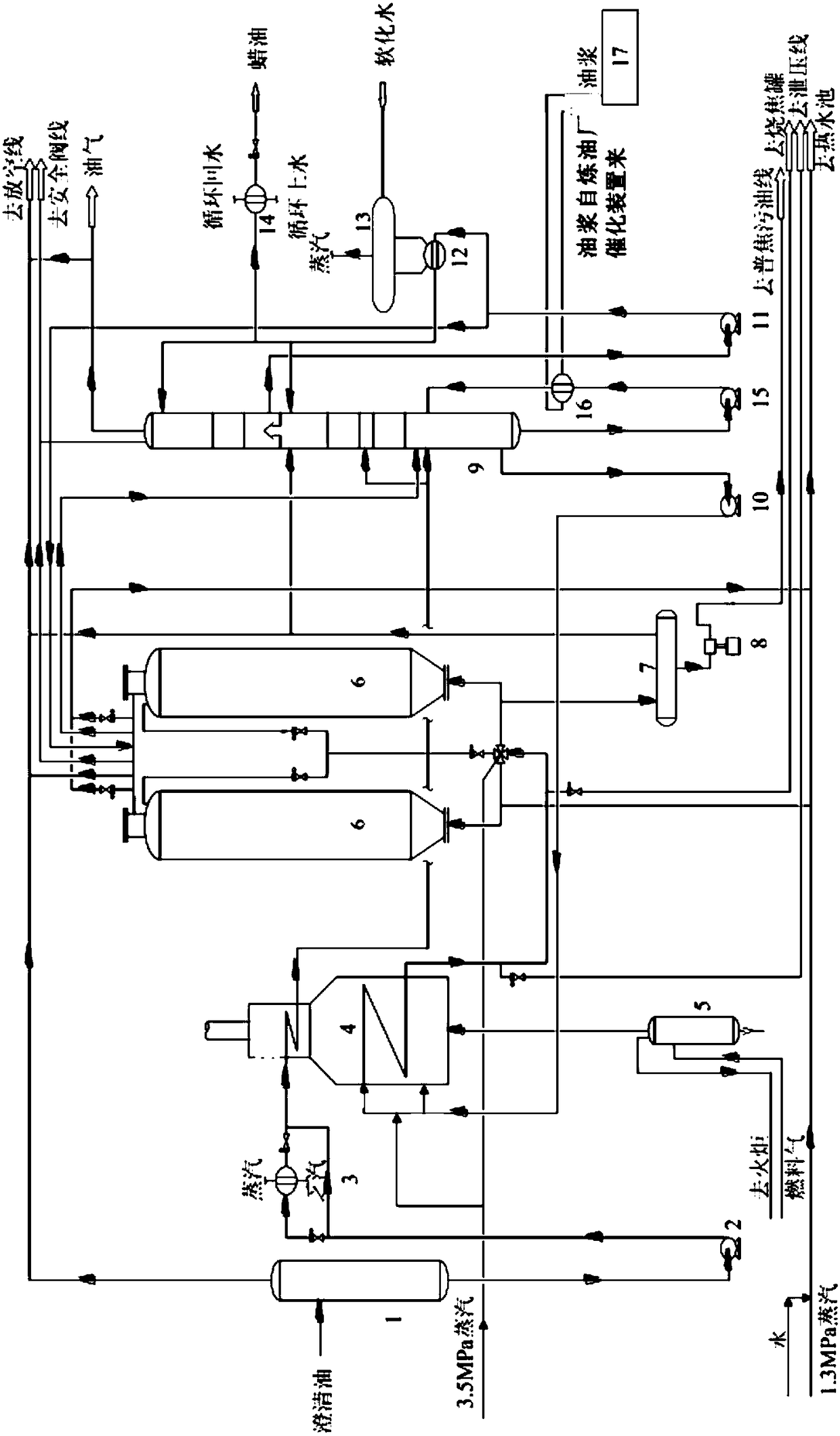

[0070] This embodiment provides a needle coke production device, such as figure 1 As shown, it at least includes: clarified oil buffer tank 1, raw material pump 2, raw material steam heater 3, heating furnace 4, fuel gas liquid separation tank 5, coke tower 6, oil rejection tank 7, oil rejection pump 8, heat exchange condensing Tower 9, radiation feed pump 10, wax oil pump 11, wax oil evaporator 12, steam drum 13, wax oil cooler 14, circulation pump 15, oil slurry-combined oil heat exchanger 16, raw material pretreatment system 17 ;

[0071] The quantity of described coke drum 6 is two;

[0072] The clarified oil buffer tank 1 is connected to the clarified oil inlet of the convection chamber of the heating furnace 4 through a pipeline, and a raw material pump 2 and a raw material steam heater 3 are arranged on the pipeline, and the clarification of the convective chamber of the heating furnace 4 The oil outlet is connected to the two clarified oil inlets of the evaporation s...

Embodiment 2

[0087] This embodiment provides a method for producing needle coke, which uses the device provided in Embodiment 1, and the method at least includes the following steps:

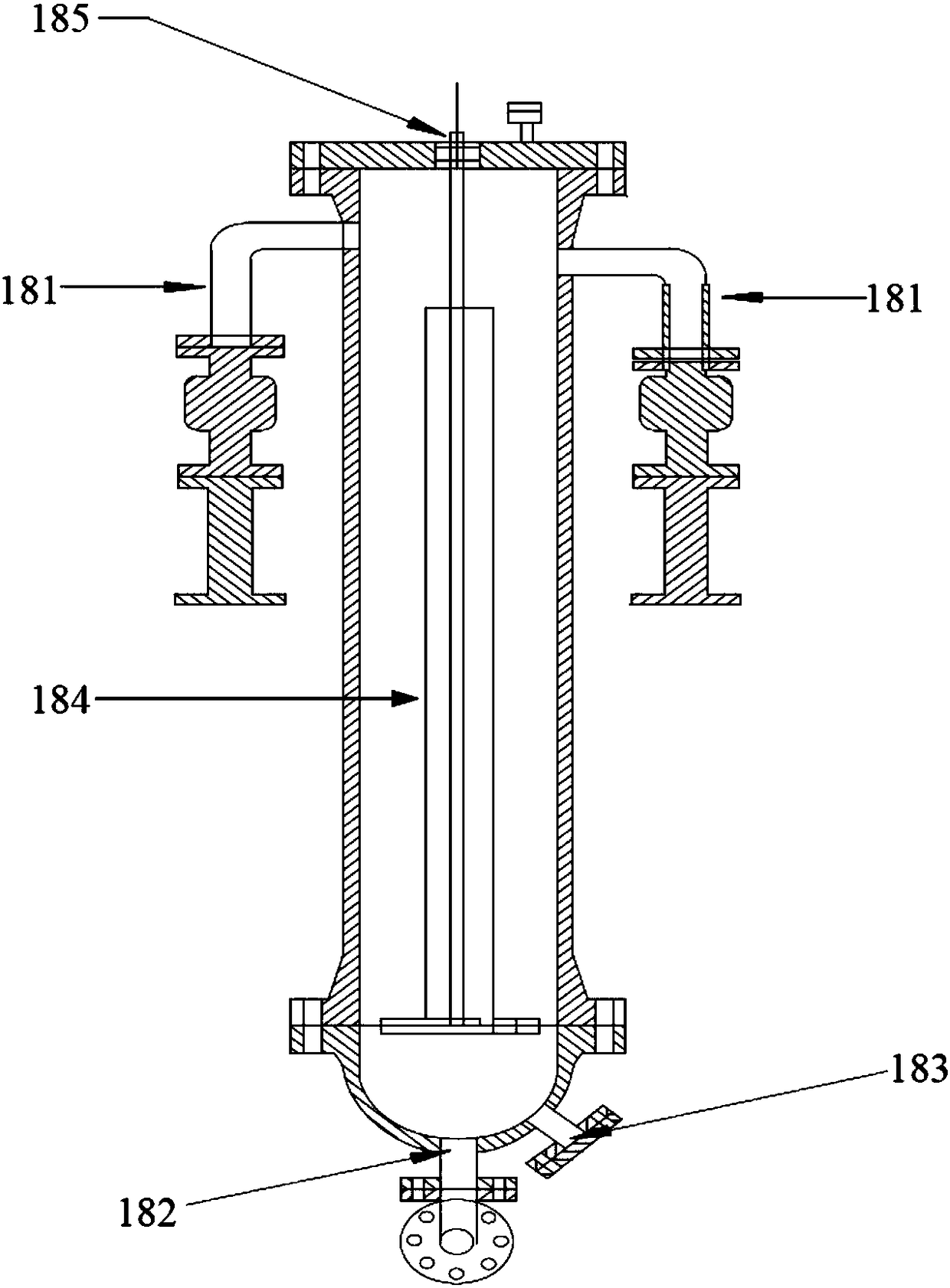

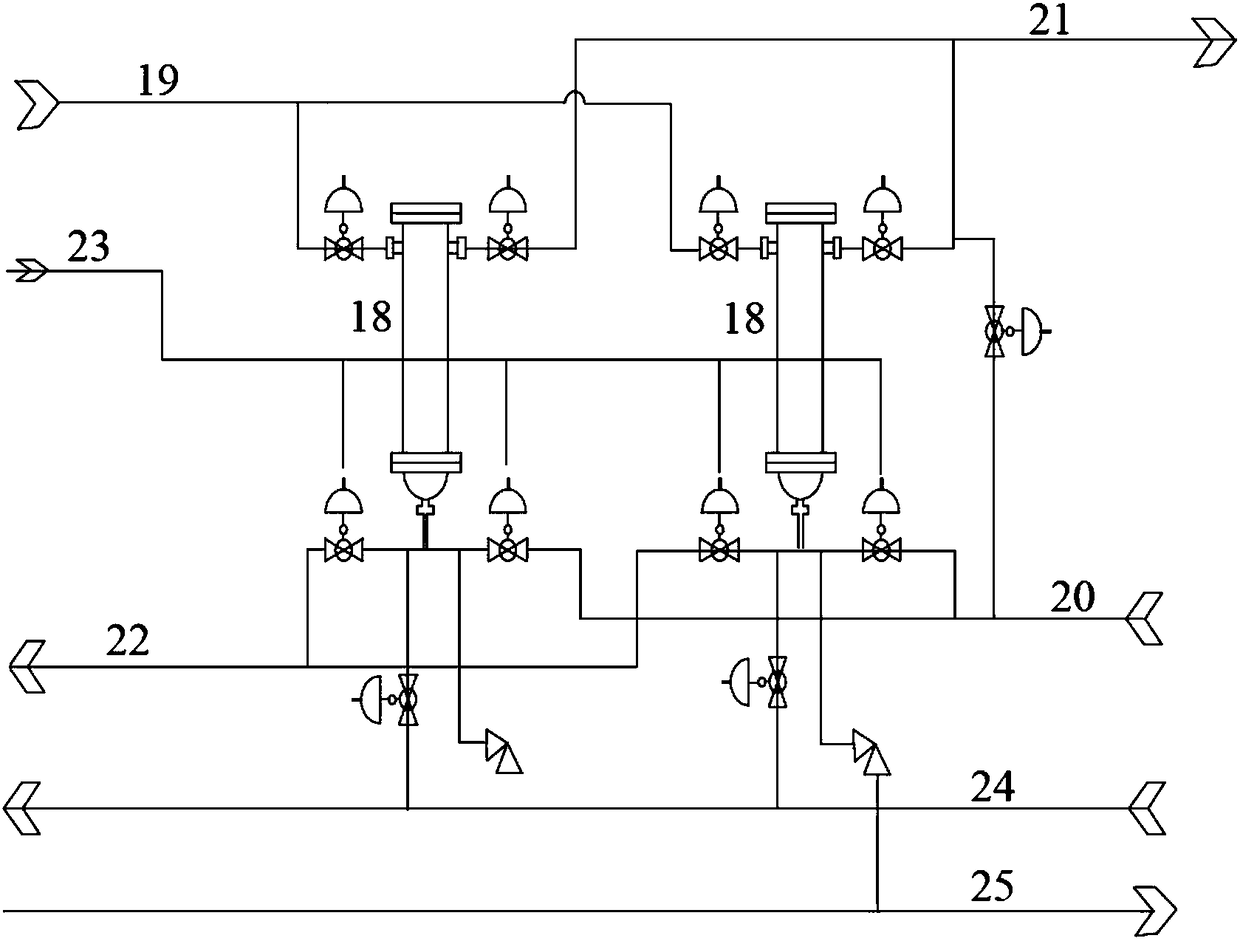

[0088] Make the oil slurry (the oil slurry is the oil slurry after heat exchange with the combined oil at the bottom of the heat exchange condensation tower 9) pass through the filter 18 in the raw material pretreatment system 17 to filter, and pass through the high-voltage lead wire 185 in the filter 18 at the same time Introduce a voltage of 35,000 to 40,000 volts to form an electromagnetic field "column" in the filter 18 to absorb impurities in the oil slurry to obtain clarified oil, which enters the clarified oil buffer tank 1, and the oil slurry is processed by the raw material pretreatment system 17 before and after pressure The difference is less than 0.45MPa; and the used filter 18 is cleaned with backwash oil, so that the backwash oil enters the used filter 18 through the backwash oil inlet for clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com