Method for treating and recycling waste water of steel plants

A technology for wastewater and steel mills, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of steel mill wastewater that cannot reuse circulating water and cannot handle high organic matter , Can not deal with high hardness or high organic matter steel factory wastewater and other problems, to achieve the effect of alleviating water shortage, protecting the environment and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

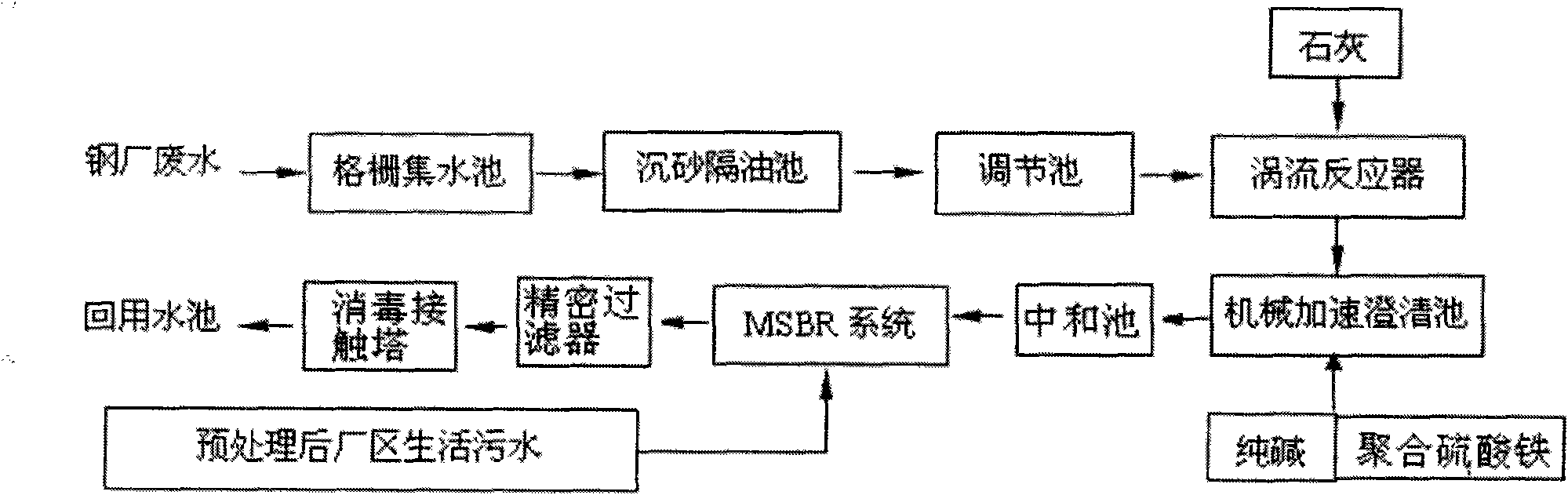

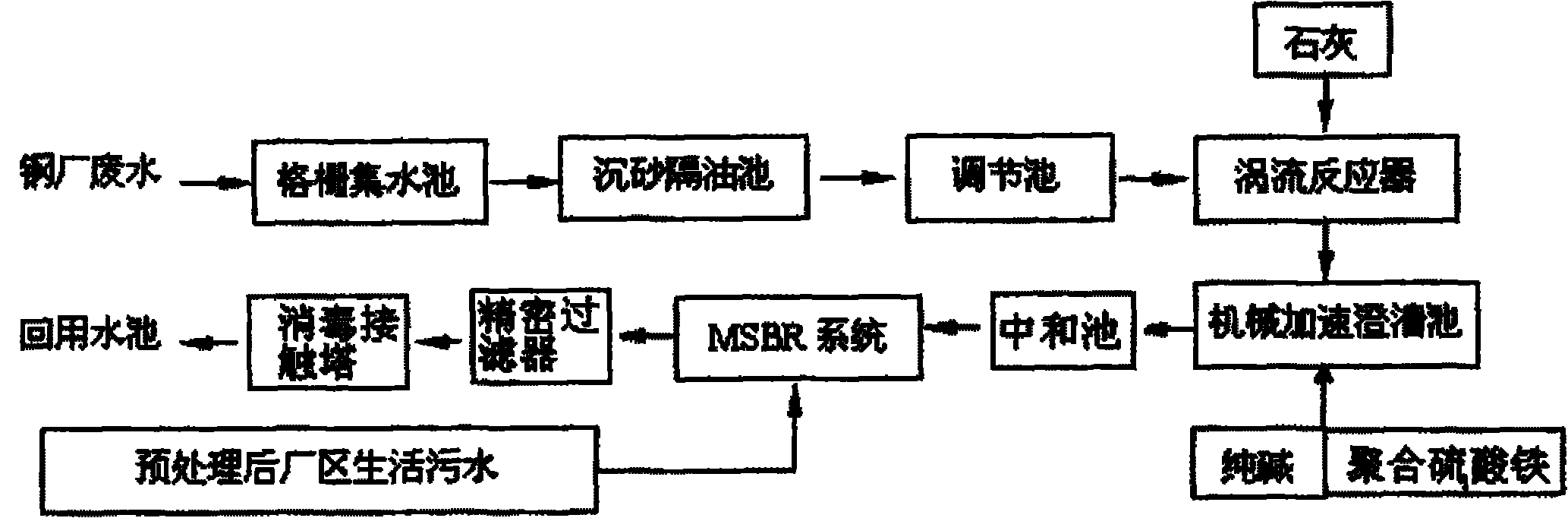

[0032] A method for treating wastewater from a steel mill and recycling it, the specific steps are:

[0033] 1) The wastewater from the steel mill passes through the grille sump, in which a mechanical grille is installed to remove bulky substances and some suspended solids with larger particle sizes in the wastewater;

[0034] 2) The submersible sewage pump lifts the waste water treated by the grid sump to the grit settling grease trap, and the grit settling grease trap is equipped with scraping mud and slag equipment to remove the silt and oil scum in the waste water. Effectively reduce sedimentation debris and floating oil substances in wastewater;

[0035] 3) The wastewater treated by the grit-set grease trap enters the regulating tank to adjust the water quality and water quantity, and then is quantitatively lifted by the pump to the vortex reactor added with lime;

[0036] 4) The wastewater treated by the vortex reactor enters the mechanically accelerated clarifier, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com