Control method and control device for steel raw material yard logistics transmission equipment

A logistics transmission and equipment control technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of unstable incoming materials, many types of raw materials in the stockyard, waste of energy and resources, etc., to avoid raw materials Effects of supply disruptions, improved equipment utilization, and increased production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

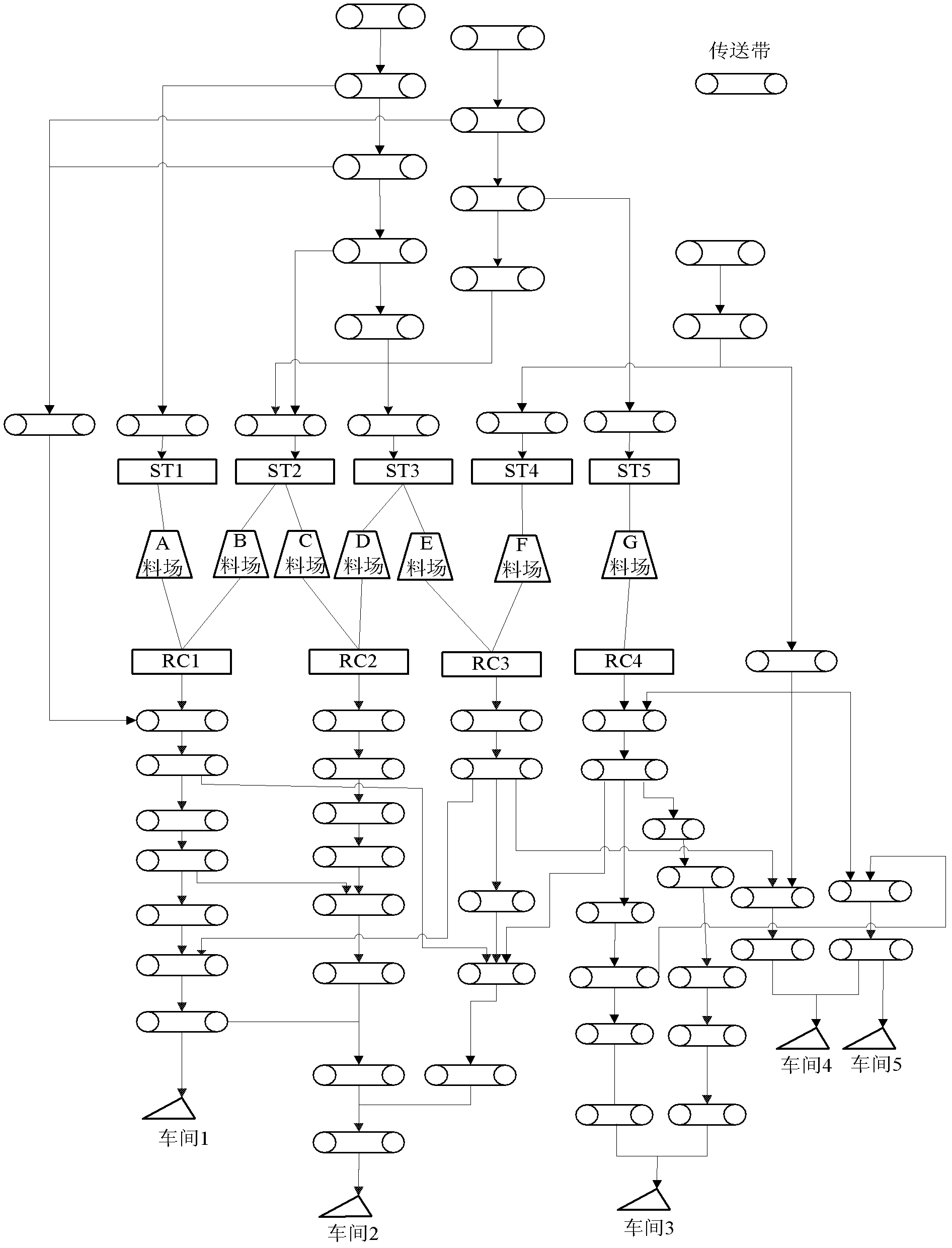

[0024] One embodiment of the present invention takes the raw material factory of a large iron and steel company as an example. It is necessary to transport 6 different batches of raw materials from the stockyard to each production workshop. There are 55 available conveyor belts, 9 starting points for transporting materials, and 5 shipping destination, such as figure 1 As shown, the time interval T 0 = 5min.

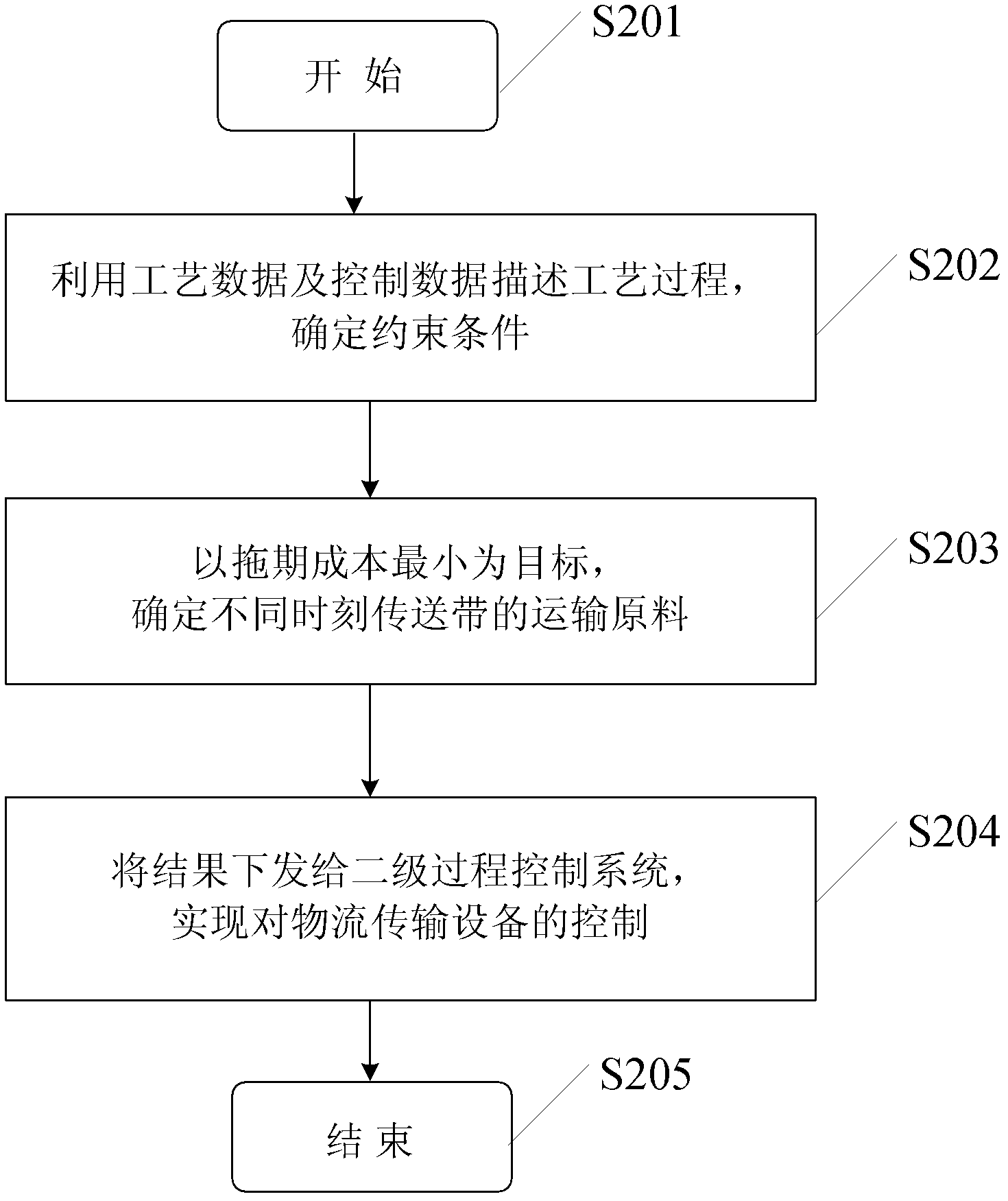

[0025] In one embodiment of the present invention, the flow chart of the control method for the logistics transmission equipment in the iron and steel raw material field is given as follows: figure 2 shown. The process starts at step 201 . In step 202, the process data and control data in the conveyor belt transmission process are downloaded from the enterprise database, and the raw material information to be input is shown in Table 1:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com