Vertical hoisting tool of piston pin

A piston pin and tooling technology, which is applied in the field of lifting tools, can solve the problems of bruising the surface of piston pins, crushing employees' fingers, smashing combined fixtures, etc., and achieves the effects of reducing processing auxiliary costs, improving work efficiency, and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and embodiments.

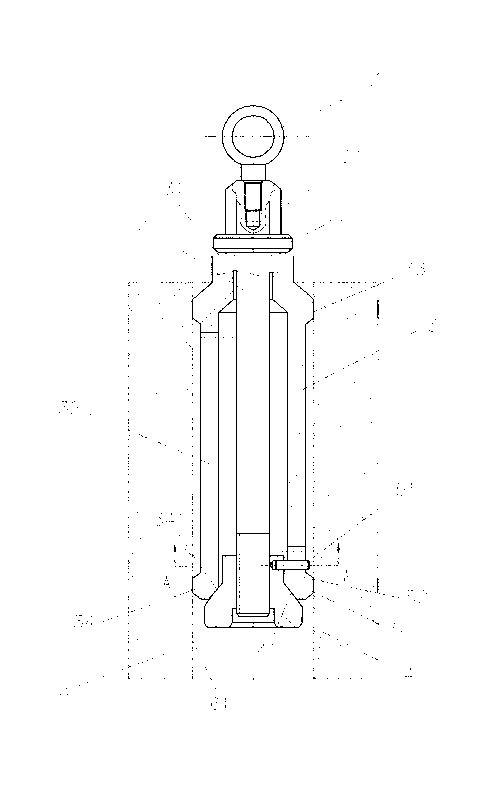

[0015] like figure 1 and figure 2 As shown, the present invention includes an eyebolt 1, an adjusting bolt 2, an elastic expansion sleeve 3, a conical top block 4 and a conical top block anti-rotation mechanism 5, the adjustment bolt 2 passes through the elastic expansion sleeve 3, and its top is provided with a wrench The stuck hexagonal head 21, to ensure that when the adjusting bolt 2 rotates, the elastic expansion sleeve 3 will not rotate thereupon; On the upper end face, to ensure that the adjustment bolt 2 will not move when it rotates. The lower end of the eyebolt 1 is fixed on the upper end of the adjusting bolt 2 through threaded connection, and the lower end of the adjusting bolt 2 is threaded with the upper end of the conical top block 4 .

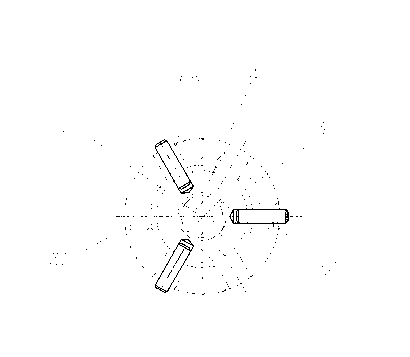

[0016] The top of the elastic expansion sleeve 3 has a polyhedral structure, and in this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com