Adsorption and catalysis integrated device for organic waste gas

A technology for adsorption and catalysis and organic waste gas, which is applied in gas treatment, incinerator, transportation and packaging, etc. It can solve the problems of low treatment efficiency of organic waste gas treatment devices, low removal rate of organic matter, secondary pollution of tail gas, etc., and achieve energy saving effect Significant, fully automated operation process, and stable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

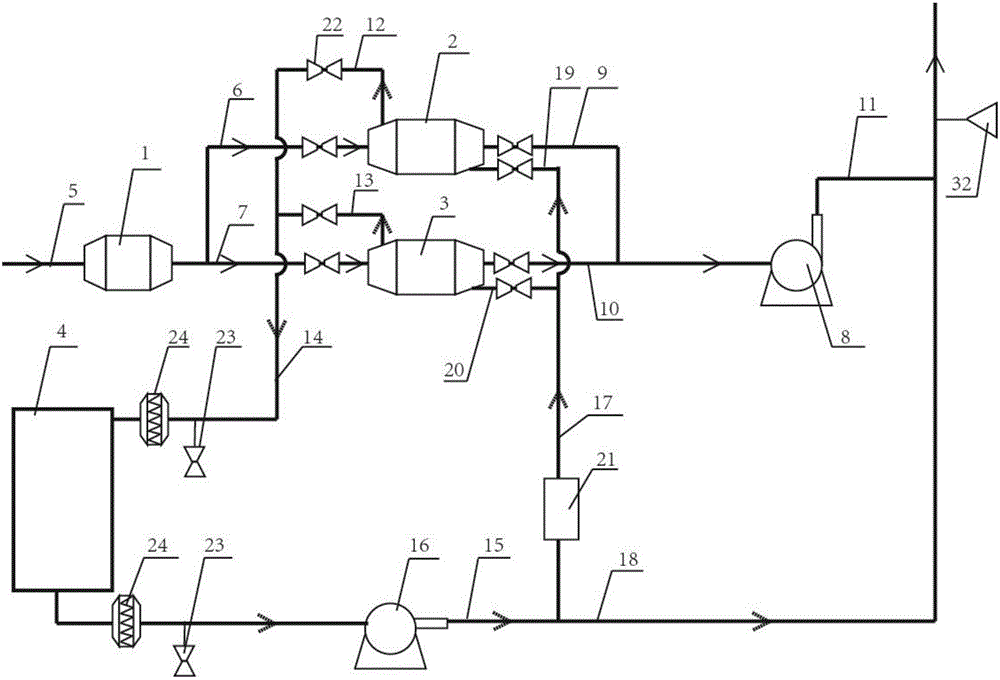

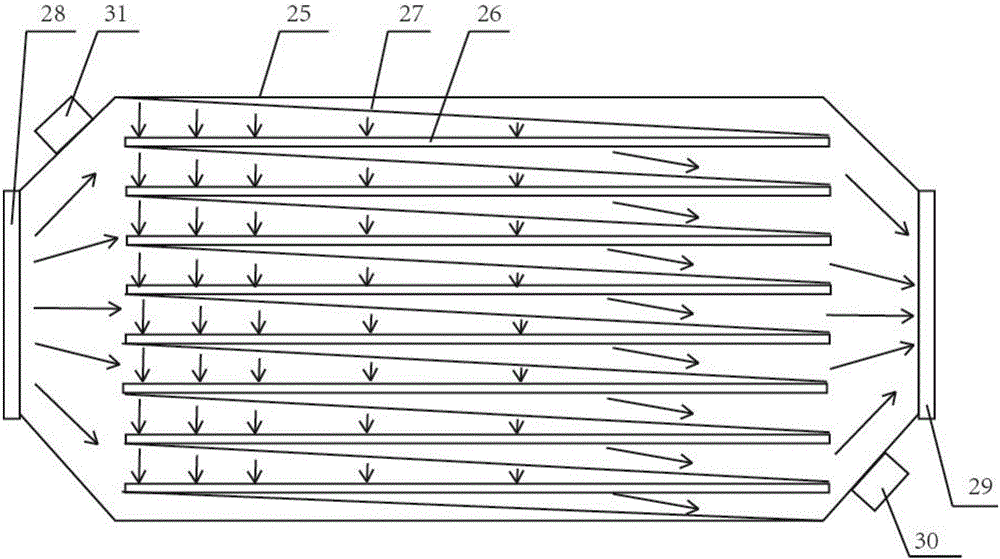

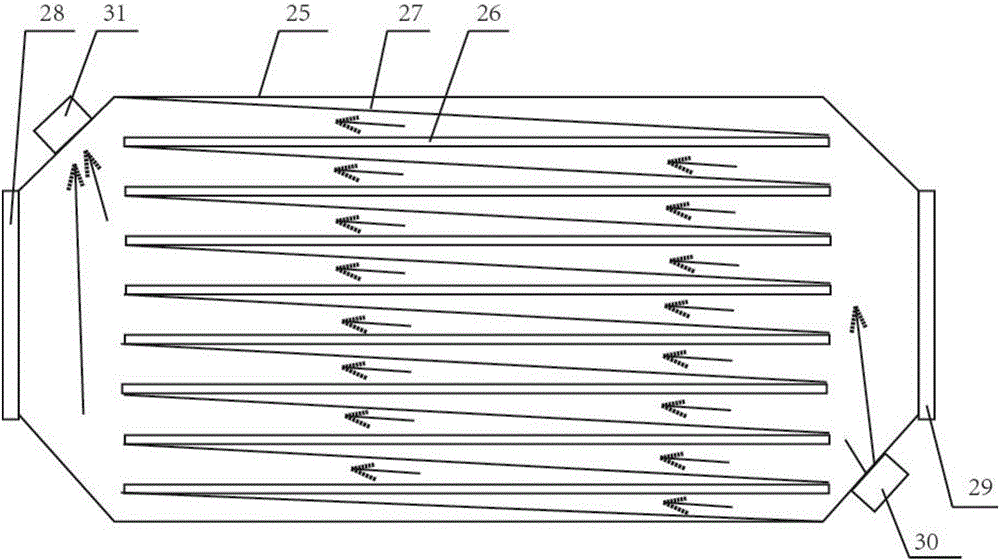

[0040]An organic waste gas adsorption and catalysis integrated device, the device includes a filter device 1, a No. 1 activated carbon adsorption box 2, a No. 2 activated carbon adsorption box 3 and a catalytic combustion bed 4. The waste gas to be treated passes through the waste gas pipeline 5 and enters the filter device 1. The filter device 1 communicates with No. 1 activated carbon adsorption box 2 and No. 2 activated carbon adsorption box 3 through No. 1 exhaust gas inlet pipe 6 and No. 2 exhaust gas inlet pipe 7 respectively. No. 1 activated carbon adsorption box 2 and No. 2 activated carbon adsorption box 3 It communicates with the adsorption main exhaust fan 8 through No. 1 net gas outlet pipe 9 and No. 2 net gas outlet pipe 10 respectively. The adsorption main exhaust fan 8 communicates with the atmosphere through the clean gas pipeline 11. The No. 1 activated carbon adsorption No. 1 desorption intake pipe 12 and No. 2 desorption intake pipe 13 are arranged on box 2 a...

Embodiment 2

[0045] Others are all the same as in the embodiment, the difference is that the filtering device is a biological trickling filter, and the biological trickling filter is cylindrical, and the inside includes a liquid collection pool 34, a filter material layer 35 and a spray tank arranged in sequence from bottom to top. Shower room 36, spray room 36 is connected with liquid sump 34 through circulation pump 37, and described filter material layer 35 comprises several filter material cylinders 38, and described filter material cylinder 38 is fixed on the biotrickling filter through filter screen 39 In the device, the filter material cylinder 28 is in the shape of a truncated cone, the cross section of the filter material cylinder 28 is circular, and the ratio of the diameter of the upper surface of the filter material cylinder 28 to the diameter of the lower surface is 0.9-0.95:1. A gas drying box 40 is arranged between the filter filter and No. 1 activated carbon adsorption box a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com