Whole-sealed aluminum alloy online refining device

A refining device and technology of aluminum alloy, applied in the field of on-line refining of aluminum alloy, can solve the problems of large consumption of graphite rotor, pollution of graphite powder to melt, poor system sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

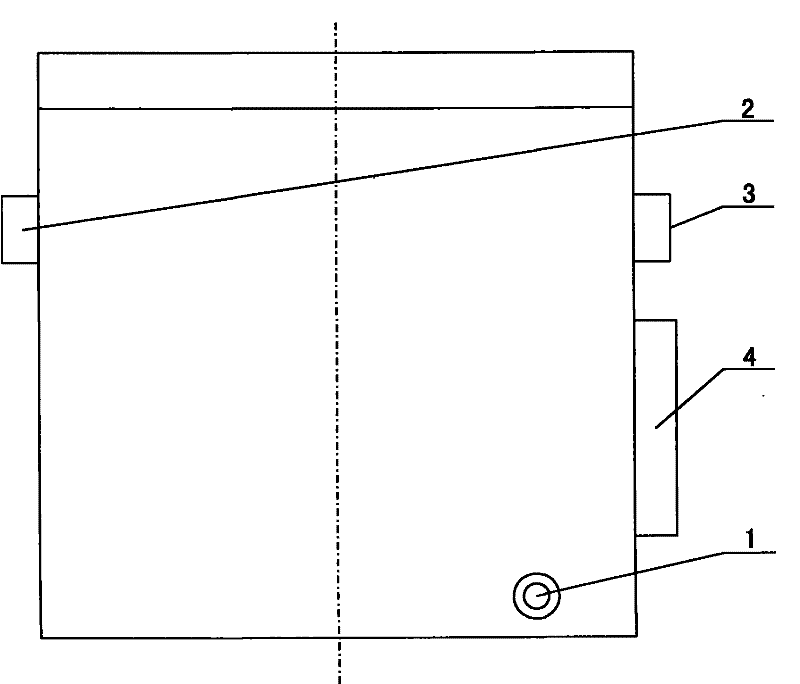

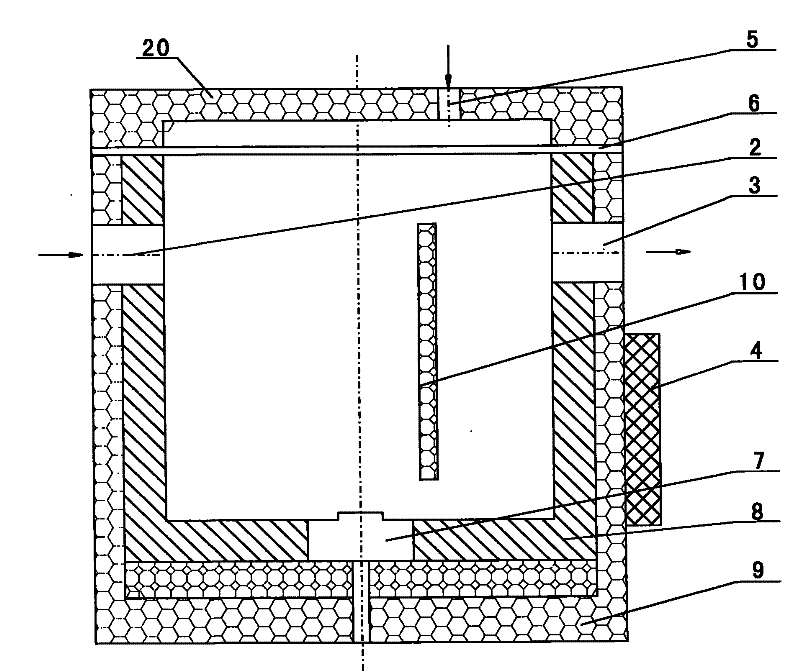

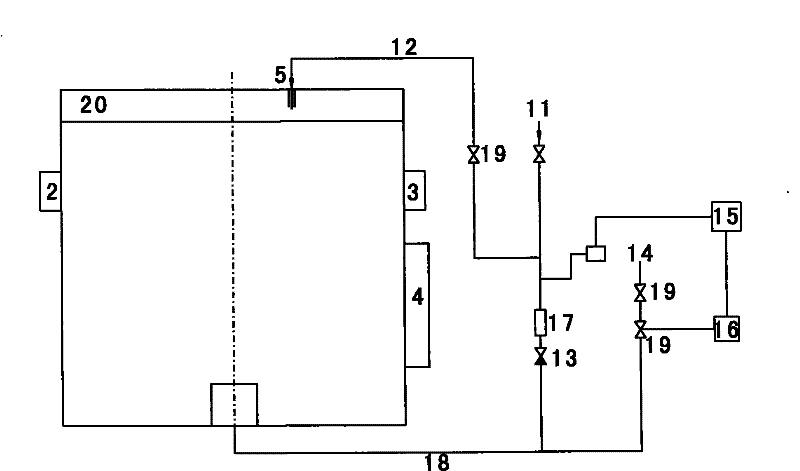

[0018] combine figure 1 , 2 Or a fully sealed aluminum alloy online refining device according to the present invention in 3, including a refining furnace structure for refining electrolytic aluminum liquid; a gas supply system for providing nitrogen in the production gas of the refining furnace and interruption of the production gas of the refining furnace The security system when the refining furnace produces gas is interrupted; the warning system that sends out the alarm signal when the production gas of the refining furnace is interrupted; the refining furnace structure of the electrolytic aluminum liquid aluminum refining is composed of an external insulation layer 9 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com