Dispersed feeding device for kettle

A feeding device and dispersion technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting reaction quality, reactant zooming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

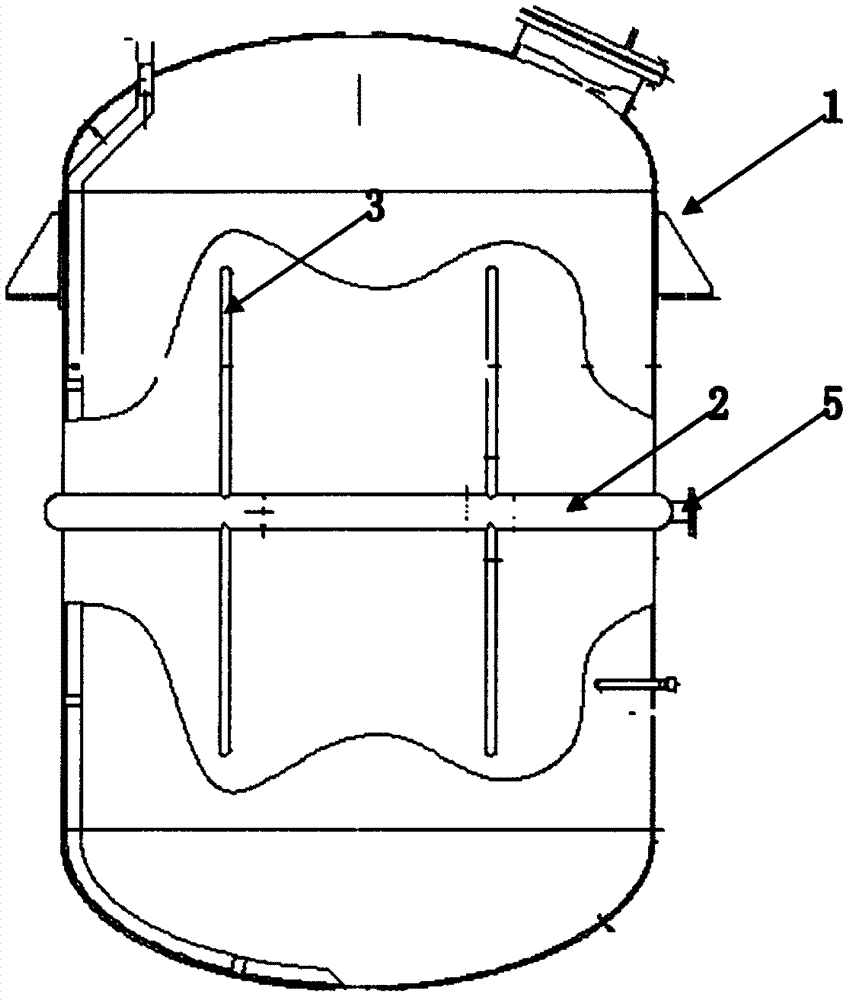

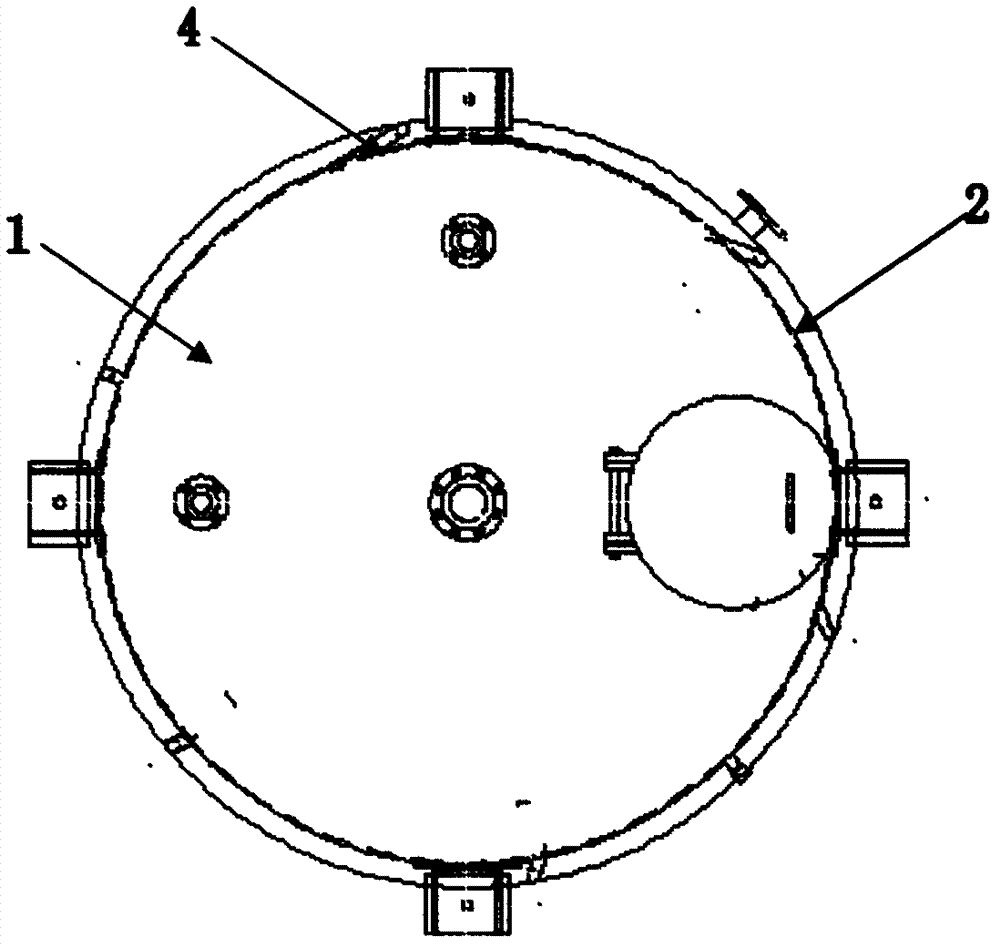

[0012] as attached figure 1 As shown, feed main pipe (2) is set around reactor still body (1), and described feed main pipe (2) is tubular body, and tubular body is close to kettle body, and its inlet end is feed inlet (5), tubular A plurality of feed branch pipes (3) are arranged on the body, and one end of the feed branch pipes (3), that is, the inlet end, is connected with the feed main pipe (2), and the outlet end extends to the reactor body up and down the reactor (1).

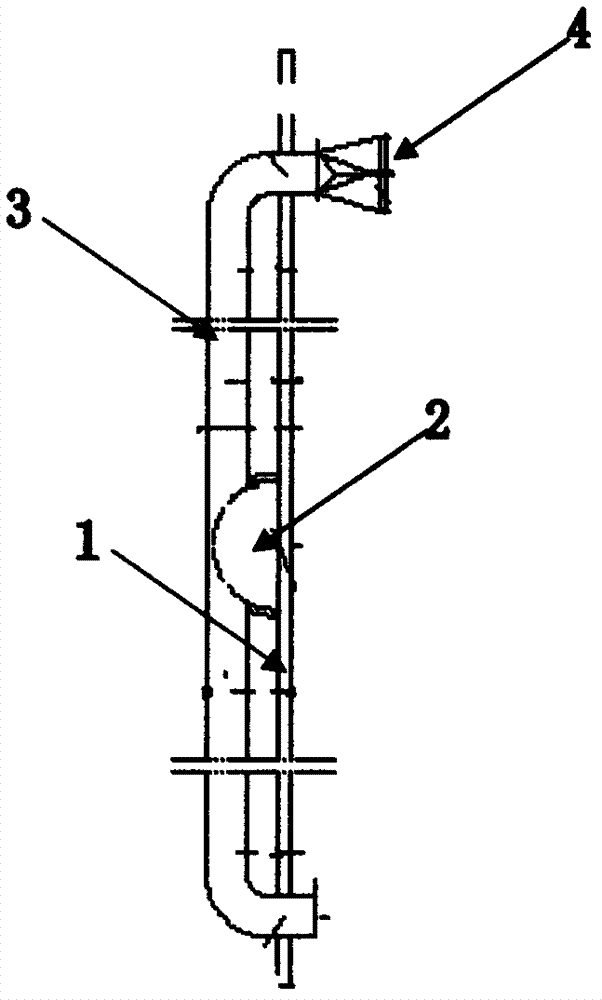

[0013] as attached figure 2 , 3 As shown, feed nozzle (4) is provided at the end of feed branch pipe (3) outlet end, and described feed nozzle (4) is flat, and it stretches into reactor (1) inner wall from feed branch pipe (3), The two-dimensional plane of the flat spout forms a certain angle with the tangential plane of the inner wall of the reaction kettle (1), and the angle should be an acute angle.

[0014] When the device is in use, the liquid material enters each feed branch pipe (3) from the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com