Solvent-free genuine leather laminating adhesive and preparation method thereof

A solvent-free, laminating adhesive technology, applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve the problems of reduced use effect, impact of storage life, and overall quality of by-products, etc., to achieve Improved heat resistance, excellent solvent resistance, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

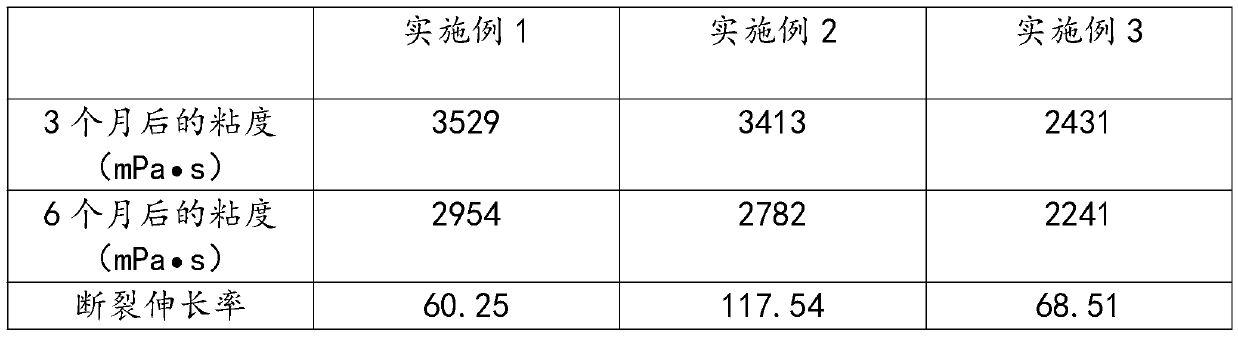

Embodiment 1

[0038] A solvent-free leather lamination adhesive, which is composed of A component, B component and C component, and A component is composed of diethylene glycol, 1,2-propylene glycol and sebacic acid in a ratio of 3:3:4 The weight percentage composition; B component is made up of xylylene diisocyanate, diphenylmethane diisocyanate and polyether polyol by weight percentage of 3:3:4, and the hydroxyl value of polyether polyol is 112mgKOH / g; C component is composed of 2,6-di-tert-butyl-p-cresol and 3,5-dimethylpyrazole in a weight percentage of 1:1;

[0039] And the weight percentage among A component, B component and C component is 5:8:2.

[0040] A preparation method of solvent-free type leather laminating glue, comprising the steps of:

[0041] Preparation of component A: first add diethylene glycol, 1,2-propanediol and sebacic acid into the stirring tank according to the weight percentage of 3:3:4, and then continuously feed nitrogen into it, and set the temperature at 2 ...

Embodiment 2

[0052] A solvent-free leather laminating glue, the difference from Example 1 is that component A is composed of diethylene glycol, 1,2-propanediol and sebacic acid in a weight percentage of 1:1:2.

[0053] A kind of preparation method of solvent-free type dermis laminating glue, the difference with embodiment 1 is that, the preparation of A component: first add diethylene glycol, 1 , 2-propanediol and sebacic acid.

Embodiment 3

[0055] A solvent-free leather lamination adhesive, the difference from Example 1 is that component C is 2,6-di-tert-butyl-p-cresol.

[0056] A preparation method of a solvent-free leather laminating glue, the difference from Example 1 is that the mixing of component C: first introduce the component B in the dry bottle into the reaction kettle, and then add 2, 6-Di-tert-butyl-p-cresol, and continue to feed nitrogen, and at the same time, introduce and mix the component A in the dry thermostat at 30 degrees for 15 minutes, and finally place it in a dry dust-free tank, To obtain solvent-free leather laminating glue;

[0057] And the application method of the solvent-free leather laminating glue obtained by the preparation method is as follows: all the solvent-free leather laminating glue placed in a dry dust-free tank is applied to the scrubbed and dried leather, and Cover with another scrubbed and dried leather, heat and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com