System for performing hydrochloric acid waste fluid spray roasting through industrial waste heat and control method

A technology of hydrochloric acid waste liquid and industrial waste heat, which is applied in the fields of metallurgy, mechanical processing and chemical industry, can solve the problems of high operating costs, and achieve low operating costs and significant energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The waste heat temperature of the industrial flue gas is about 780°C. The heat of the waste heat flue gas can meet the maximum heat demand of the roaster under the condition of full load operation, and the temperature of the flue gas can also meet the temperature required for the decomposition reaction in the roaster (500-650°C).

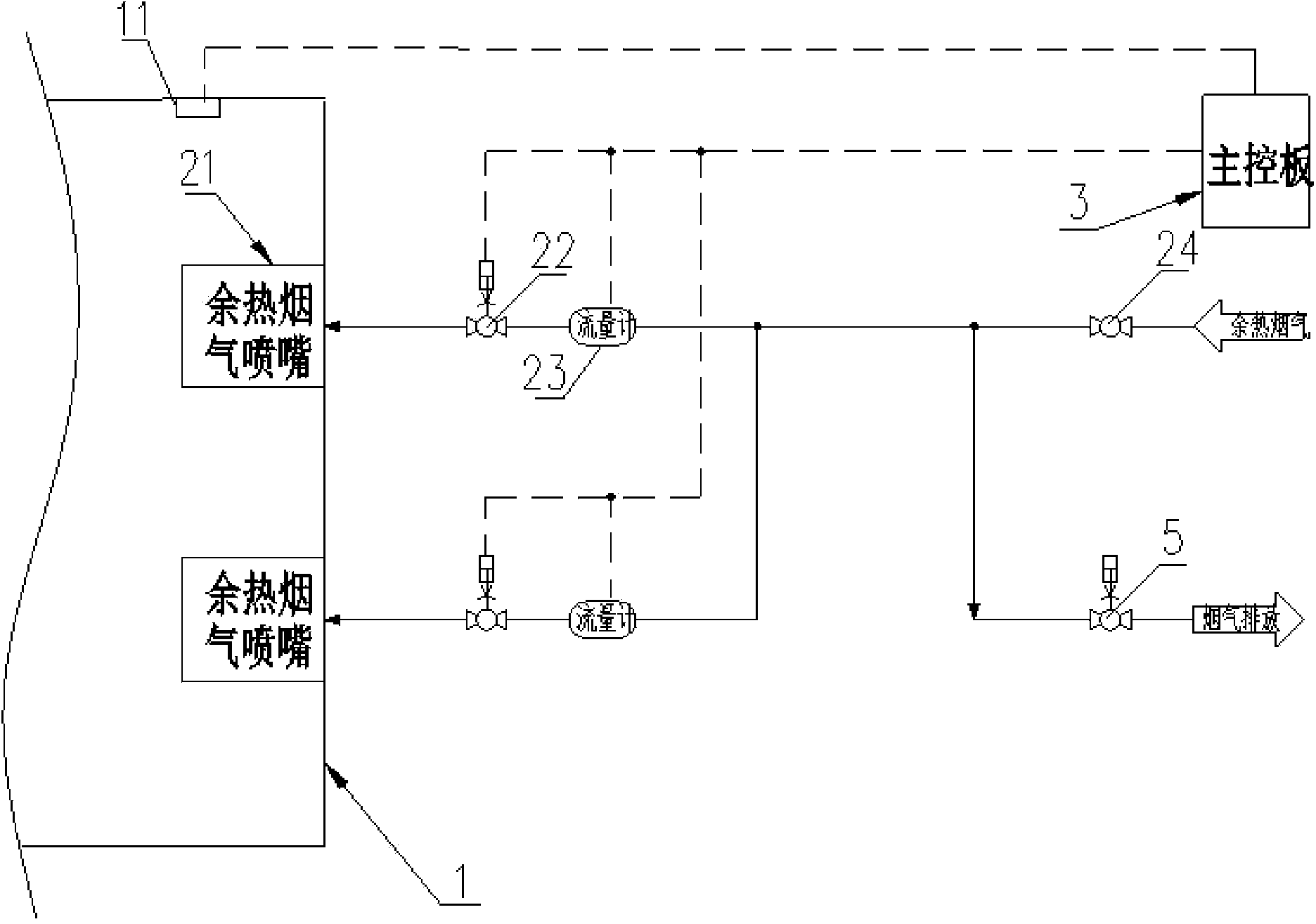

[0042] Such as figure 1 As shown, in order to realize the utilization of industrial waste heat in the hydrochloric acid regenerative roaster of spray roasting method to provide heat source, one or more waste heat flue gas nozzles should be installed along the tangential direction on the furnace waist of the roaster, and the flow rate of the waste heat flue gas nozzles should be set to 20m / s. The nozzle adopts a tapered type, shrinking from the outside to the inside. Each waste heat flue gas nozzle is connected with the waste heat heat supply pipe, and the waste heat flow regulating valve 22, waste heat flow meter 23 and waste heat switch valv...

Embodiment 2

[0047] The waste heat temperature of industrial flue gas is about 350°C. The heat of waste heat flue gas can meet the maximum heat demand of the roaster under the condition of full load operation, but the temperature of the flue gas cannot meet the temperature required for the decomposition reaction in the roaster (500-650°C). Also can not satisfy the requirement of iron oxide powder quality.

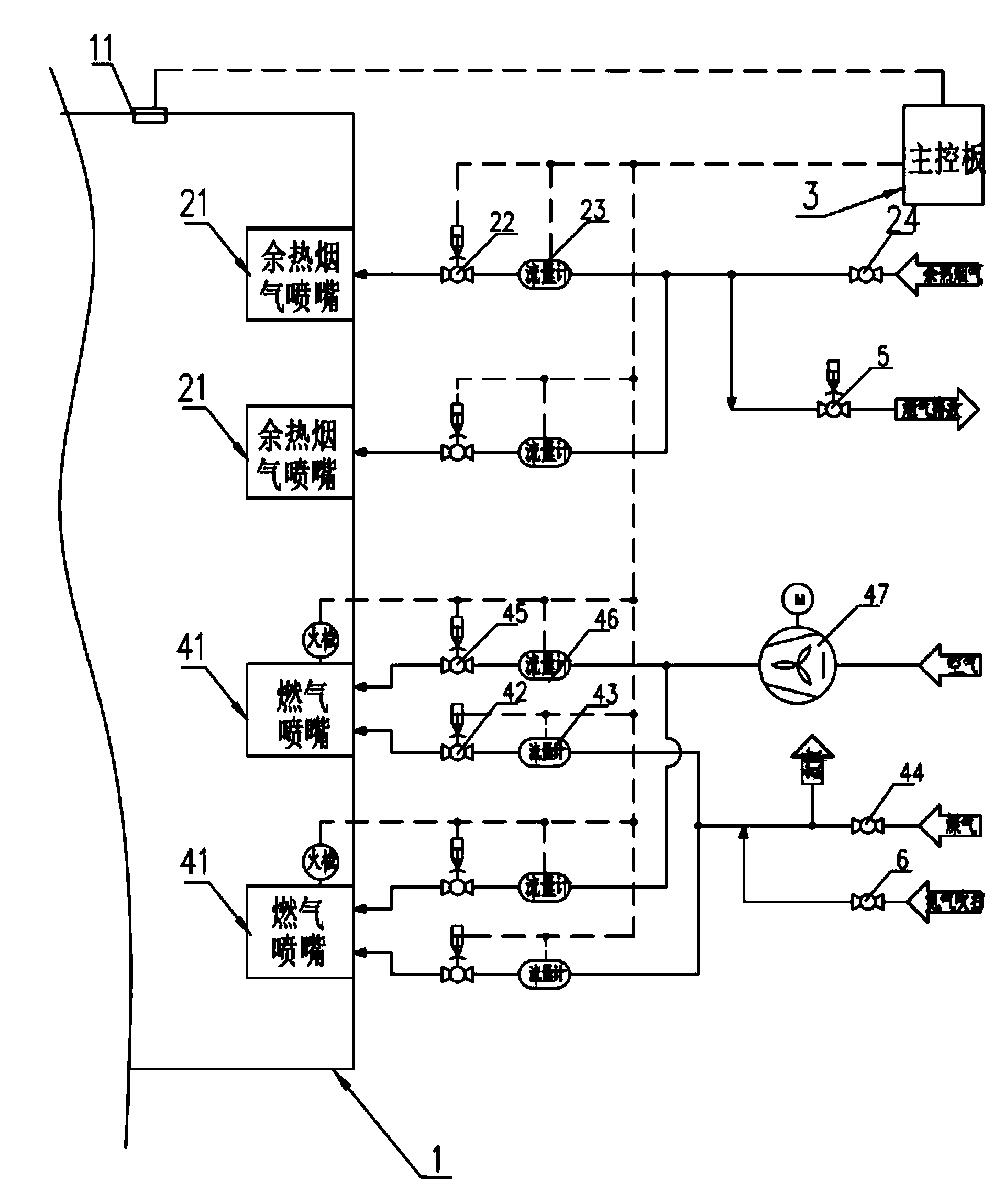

[0048] Such as figure 2 As shown, in order to realize the utilization of industrial waste heat in the hydrochloric acid regenerative roaster of spray roasting method to provide heat source, one or more waste heat flue gas nozzles should be installed along the tangential direction on the furnace waist of the roaster, and the flow rate of waste heat flue gas nozzles should be set to 25m / s. The nozzle adopts a tapered type, shrinking from the outside to the inside. Each waste heat flue gas nozzle is connected with a waste heat heat supply pipe, and a waste heat flow regulating valve 22 ,...

Embodiment 3

[0056] The waste heat temperature of industrial flue gas is about 700°C. Under normal circumstances, the heat of waste heat flue gas can meet the maximum heat demand of the roaster under the condition of full load operation, and the temperature of waste heat flue gas can also meet the temperature required for the decomposition reaction in the roaster (500-650 ℃), but within a certain period of time it cannot meet the heat supply requirements of the roaster of the acid regeneration unit.

[0057] Such as figure 2 As shown, under normal working conditions, waste heat is the main source of heat, supplemented by external gas heating. When the external heating is completely interrupted, the full gas heat source is used for heating. In order to realize the utilization of industrial waste heat in the spray roasting hydrochloric acid regenerative roaster to provide heat source, one or more waste heat flue gas nozzles should be installed along the tangential direction on the furnace w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com