Process for synthesizing high performance water reducing agent of polyocarboxy acid

A synthesis process and high-performance technology, applied in the field of polycarboxylate high-performance water reducer synthesis process, can solve the problems of cumbersome process control and complicated process, and achieve the effect of simple process flow, simple process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

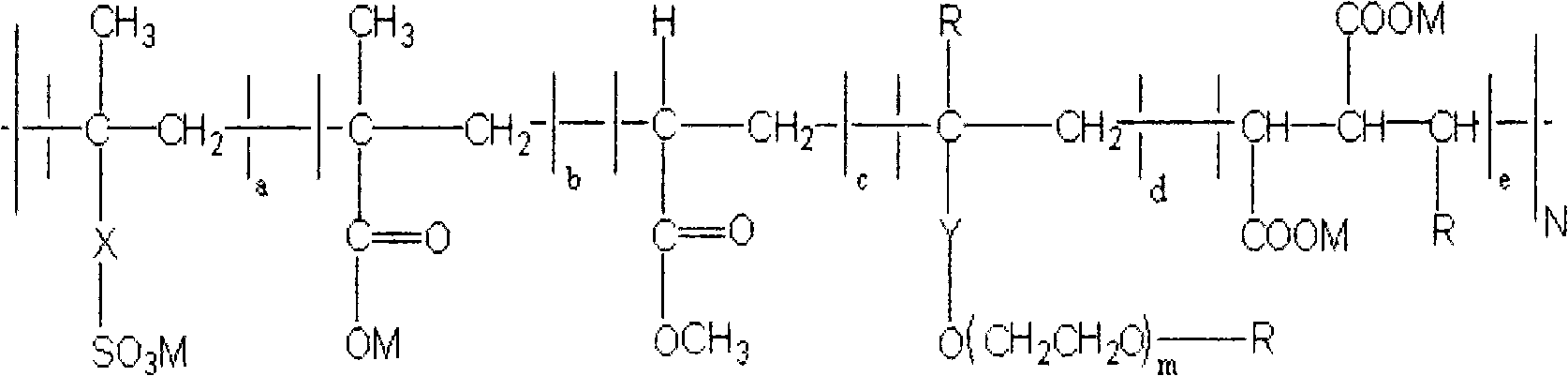

Method used

Image

Examples

Embodiment Construction

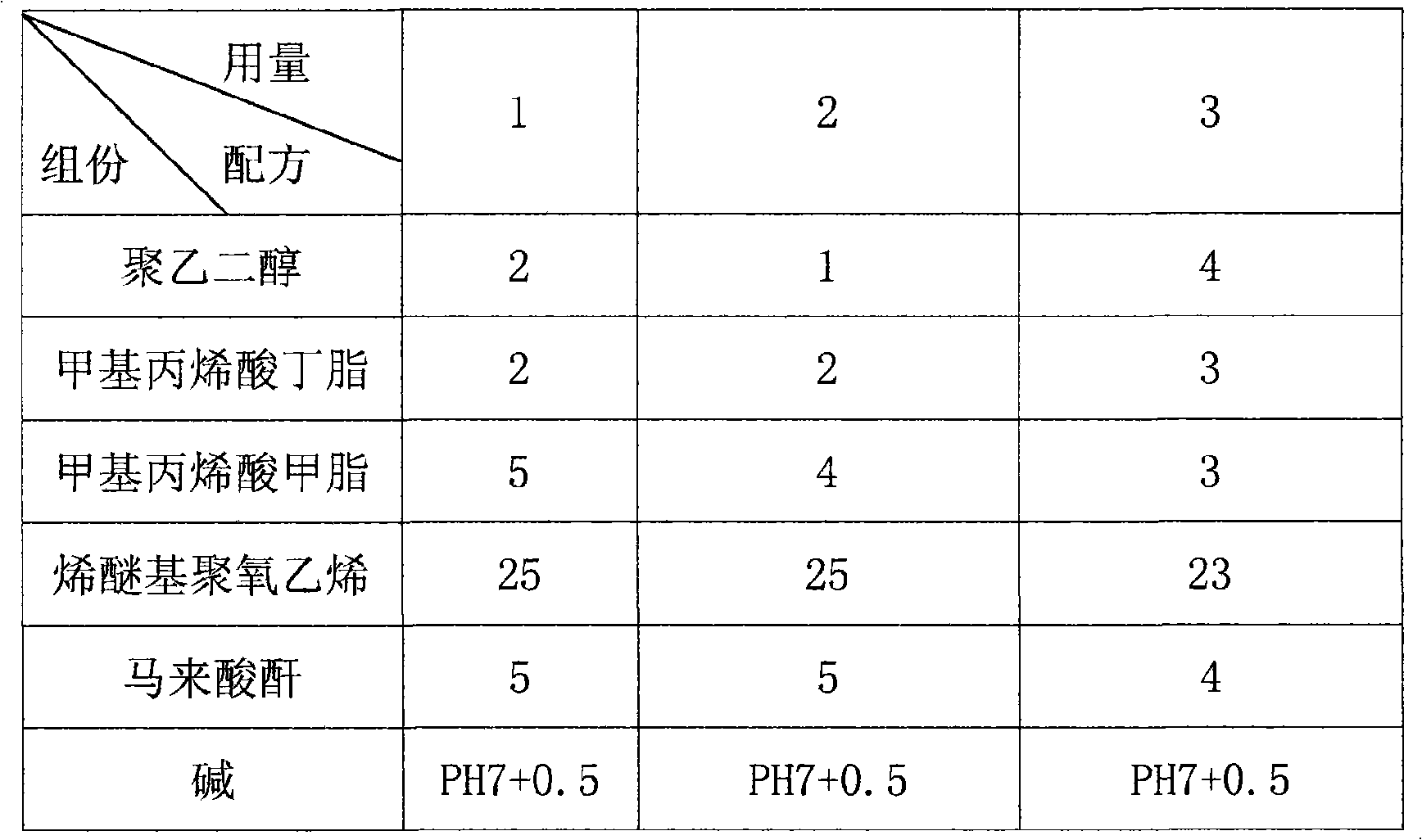

[0021] The formula of the present invention is as follows: parts by weight

[0022]

[0023] Technology of the present invention is as follows:

[0024] 1. Weigh various raw materials according to the formula;

[0025] 2. Pour water into the reactor;

[0026] 3. Add polyethylene glycol, butyl methacrylate, methyl methacrylate, ether-based polyoxyethylene, maleic anhydride and alkali in sequence, melt, stir and mix in the reaction kettle;

[0027] 4. Raise the temperature to 70-100°C. When the liquid in the kettle appears a yellow-brown viscous liquid, it indicates that the reaction is complete and complete. This means that the pH value should be 7-8, which is generally weakly alkaline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com