Polyphosphate oligomer flame retardant and preparation method thereof

A polyphosphate and oligomer technology, applied in the field of polyphosphate oligomer and phosphate oligomer flame retardant, can solve the problems of increasing process complexity and difficulty, and achieve efficient preparation, low volatile content and less , the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

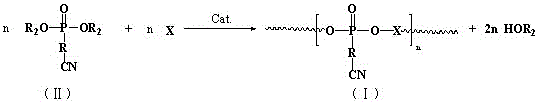

Method used

Image

Examples

Embodiment 1

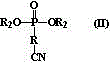

[0037] Add 456g (2mol) of bisphenol A (BPA), 378g (2.13mol) of diethyl nitrile methyl phosphate, and 4.2g (0.5%) of catalyst NaOH into a multi-necked flask equipped with a stirrer and nitrogen inlet and outlet. After replacing the air, pass nitrogen protection, gradually increase the temperature, and start stirring after the BPA melts. The temperature is gradually raised from 140°C to 200°C. At the same time, the pressure is gradually reduced from 760mmHg to the final residual pressure of 10mmHg. The entire reaction process takes 3.5 to 5 hours. The step-by-step temperature rise and negative pressure are controlled as follows:

[0038] 140°C×1.5h×760mmHg, 160°C×1h×200mmHg, 180°C×0.5h×50mmHg, 200°C×0.5h×10mmHg, after the reaction, a light brown viscous liquid was obtained with a yield of 90%. The viscosity of the product was measured as 820mPa.

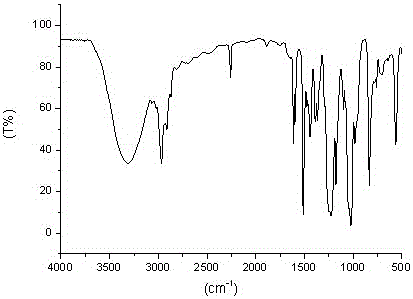

[0039] Infrared Spectrum ( figure 1 ) shows that at 2258cm -1 Nitrile characteristic absorption appears at 1246cm -1 The left and...

Embodiment 2

[0041] Using tetrabutylphosphine hydroxide and NaOH as the composite catalyst (the weight ratio of the two is 1:1), the amount of catalyst added is 0.3% (2.5g) of the total weight of 456g of bisphenol A (BPA) and 378g of diethyl nitrile methyl phosphate , other with embodiment 1. After the reaction was finished, the polyphosphate oligomer of light brown viscous liquid was obtained, the yield was 92%, and the measured product viscosity was 850mPa.

Embodiment 3

[0043] Lanthanum acetylacetonate was used as the catalyst, and the amount of the catalyst added was 0.3% (2.5 g) of the total weight of 456 g of bisphenol A (BPA) and 378 g of diethyl nitrile methyl phosphate. Others were the same as in Example 1. After the reaction was finished, a polyphosphate oligomer of light brown viscous liquid was obtained, the yield was 89%, and the measured product viscosity was 780mPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com