Novel continuous process for preparing acetonitrile

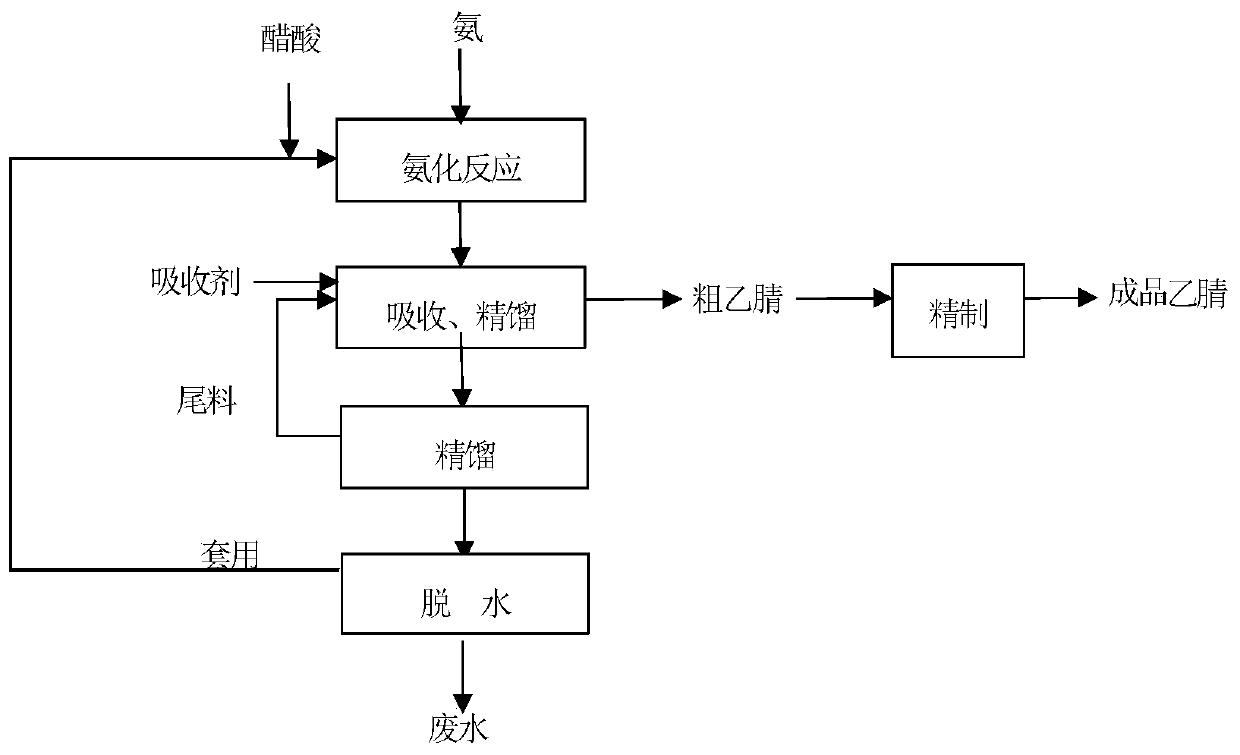

A new process, acetonitrile technology, is applied in ammonia-carboxylic acid reaction preparation, organic chemistry, carboxylic acid nitrile purification/separation, etc. It can solve the problems of harsh process conditions, low acetonitrile yield, troublesome production, etc., and achieve low overall cost , Reduce equipment investment and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: a kind of continuous process for preparing acetonitrile:

[0044] (1) Reaction process

[0045] Preheat the liquid ammonia to 150-200°C, preheat the acetic acid or the mixed solution with recovered acid to 200-250°C, the two gases enter the top of the fixed-bed reactor to mix, and pass through the distributor through the fixed-bed reactor with catalyst for reaction Reactor: The two materials are ammonified at 360-365°C under the action of a catalyst, the top pressure of the fixed-bed reactor is 5Kpa-25Kpa, the molar ratio of acetic acid to ammonia in the mixed solution is 1:1.2, and the catalyst load is 0.3t / (m 3 *h), reaction residence time: 7s.

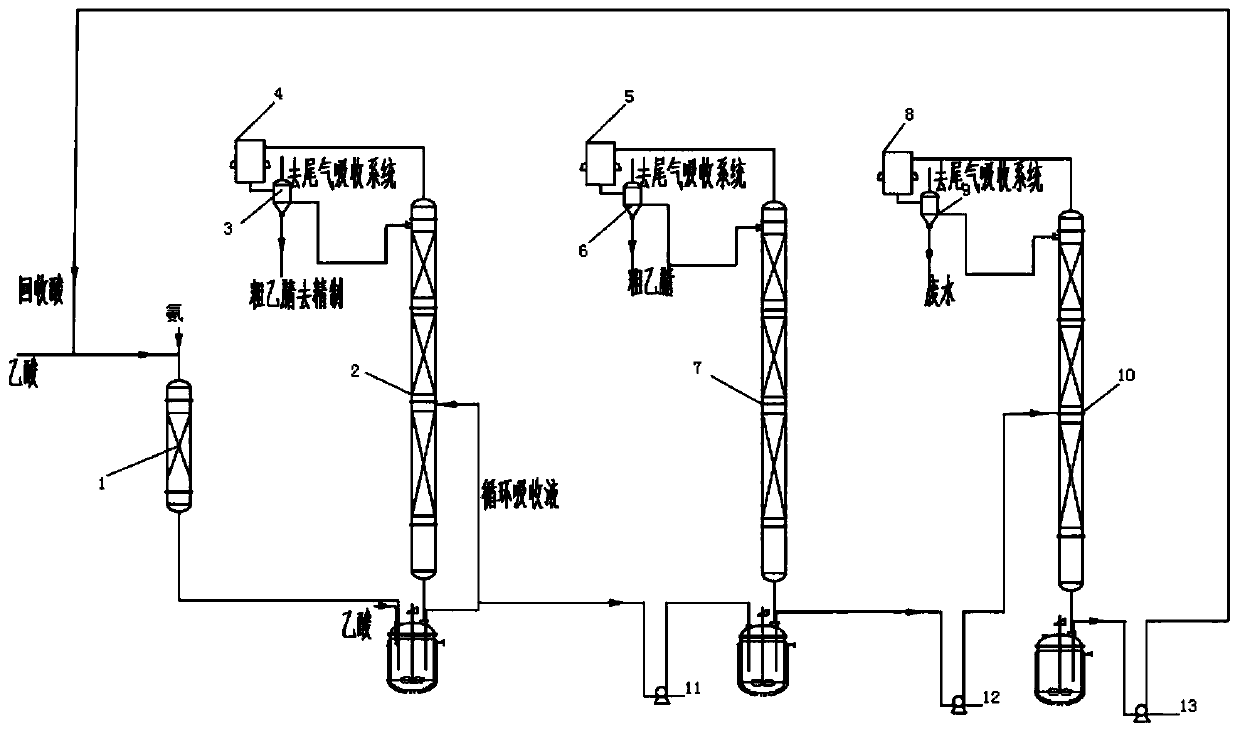

[0046] (2) Separation process

[0047] The separation tower is divided into upper and lower sections, the lower section is the spray absorption section, the upper section is the rectification section, and the tower kettle is the absorption liquid, which enters through the top of the spray absorption section th...

Embodiment 2

[0051] Embodiment 2: a kind of continuous process for preparing acetonitrile:

[0052] (1) Reaction process

[0053] Preheat the liquid ammonia to 200-300°C, preheat the acetic acid or the mixed solution with the recovered acid to 250-300°C, the two gases enter the top of the fixed-bed reactor to mix, and pass through the distributor to react through the fixed-bed with catalyst Reactor: The two materials are ammonified at 450°C under the action of a catalyst, the top pressure of the fixed bed reactor is 20Kpa-25Kpa, the molar ratio of acetic acid to ammonia in the mixed solution is 1:0.9, and the catalyst load is 2t / (m 3 *h), reaction residence time: 4s.

[0054] (2) Separation process

[0055] The separation tower is divided into upper and lower sections, the lower section is the spray absorption section, the upper section is the rectification section, and the tower kettle is the absorption liquid, which enters through the top of the spray absorption section through the ext...

Embodiment 3

[0059] Embodiment 3: a kind of continuous process for preparing acetonitrile:

[0060] (1) Reaction process

[0061] Preheat the liquid ammonia to 150-200°C, preheat the acetic acid or the mixed solution with recovered acid to 200-250°C, the two gases enter the top of the fixed-bed reactor to mix, and pass through the distributor through the fixed-bed reactor with catalyst for reaction Reactor: The two materials are ammonified at 400°C under the action of a catalyst, the top pressure of the fixed bed reactor is 10Kpa-15Kpa, the molar ratio of acetic acid to ammonia in the mixed solution is 1:0.2, and the catalyst load is 1t / (m 3 *h), reaction residence time: 7s.

[0062] (2) Separation process

[0063] The separation tower is divided into upper and lower sections, the lower section is the spray absorption section, the upper section is the rectification section, and the tower kettle is the absorption liquid, which enters through the top of the spray absorption section through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com