Resource utilization method and device for ammonium fluoride waste brine

A waste brine and ammonium fluoride technology, applied in chemical instruments and methods, metallurgical wastewater treatment, calcium/strontium/barium fluoride, etc., can solve the problems of enrichment of impurities and no export of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

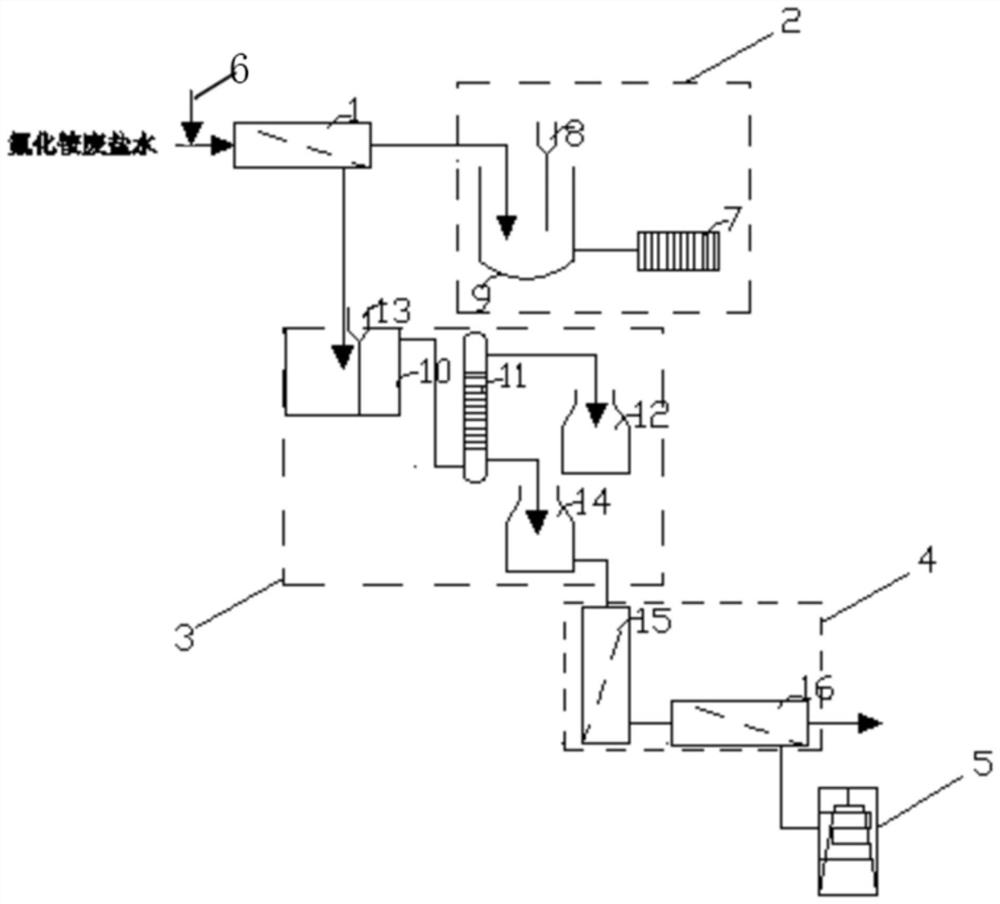

Method used

Image

Examples

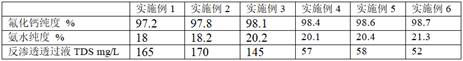

Embodiment 1

[0048]Fluorinated abiotic water was filtered after 5 μm security filter, and the nanofiltration membrane was used to intercept the molecular weight 200Da, and the operating pressure was 1.5 MPa, concentrated by 8 times, and the stable flux reached after operation 2h. 20 l / m2· H, you can remove SO42-, CA2+Mg2+Equisical and other multivalent impurity ions, obtained nanofiltration membrane osmotic sulfate 0.1 g / l, COD201Mg / L, ammonia nitrogen 25 g / L, ammonium fluoride 49g / L; nanofiltration permeation Add CA (OH)261g / L, after the reactor is fully reacted, f-Change to CAF2The calcium fluoride tapers were washed with pure water, and the calcium fluoride products were dried; nanofiltration membrane concentrates were added to CA (OH)261g / L, after the adequate reaction pH reaches 12, join (NH4)2CO35.2g / L, after the reactor is fully reacted, make CA2+Change to Caco3Entering the stripper deamper, obtaining ammonia water, stripping residual liquid re-enters the ultrafiltration m...

Embodiment 2

[0050]Fluorinated abiotic water was filtered through a 5 μm security filter into the nanofiltration membrane separation, and the nanofiltration membrane of 150 DA was used, and the operating pressure was 1.5 MPa, concentrated by 8 times, and the stable flux reached after operation 2h. 18L / m2· H, you can remove SO42-, CA2+Mg2+Equisical impurity ions, obtained nanofiltration membrane osmotic sulfate 0.07 g / l, COD165 mg / L, ammonia nitrogen 25 g / L, ammonium fluoride 50 g / L; nanofiltration membrane permeation Add CA (OH)261.6g / L, after the reactor is fully reacted, f-Change to CAF2The calcium fluoride tapers were washed with pure water, and the calcium fluoride products were dried; nanofiltration membrane concentrates were added to CA (OH)262g / L, after the adequate reaction pH reaches 12, join (NH4)2CO35.28g / L, after the reactor is fully reacted, make CA2+Change to Caco3Entering the stripper deammine, obtaining ammonia water, the stripping residue re-enters the ultrafiltr...

Embodiment 3

[0052]Fluorinated abiotic water was filtered through a 5 μm security filter, and the nanofiltration membrane was separated. It used a nanofiltration membrane of 300 Da, which was 1.5 MPa, and 10 times concentrated. After operation 2h, the stable flux is 21L / m.2· H, you can remove SO42-, CA2+Mg2+Equisical and other multivalent impurity ions, obtained by nanofiltration membrane osmotic sulfate 0.14 g / l, COD205 mg / L, ammonia nitrogen 27 g / L, ammonium fluoride 50 g / L; nanofiltration permeation Add CA (OH)261.6g / L, after the reactor is fully reacted, f-Change to CAF2The calcium fluoride tapers were washed with pure water, and the calcium fluoride products were dried; nanofiltration membrane concentrates were added to CA (OH)261g / L, after the adequate reaction pH reaches 12, join (NH4)2CO35.2g / L, after the reactor is fully reacted, make CA2+Change to Caco3Entering the stripper deammine, obtaining ammonia water, the stripping residue re-enters the ultrafiltration membrane f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com