Method and device for producing titanium by fused salt electrolysis process

A technology of molten salt electrolysis and mixed molten salt, applied in electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of high energy consumption, high cost of raw material preparation, unsatisfactory product purity, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

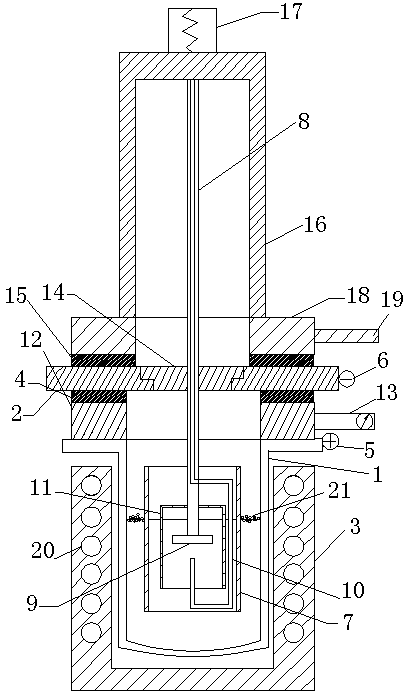

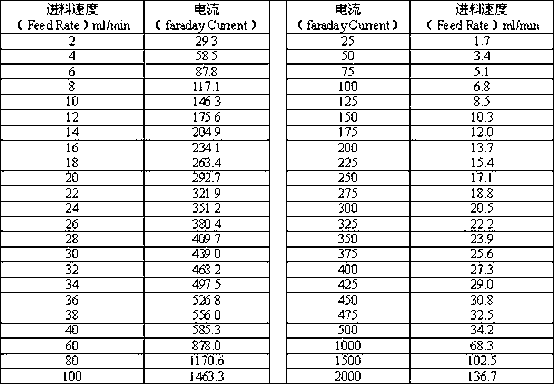

[0060] First put sodium chloride and potassium chloride into the electrolytic reaction pot, the molar ratio of sodium chloride and potassium chloride is 1:1; figure 1 The device for producing titanium by molten salt electrolysis shown in the figure is connected, and the vacuum pumped to 5×10 through the vacuum pumping device of the electric reaction pot -1 pa, start the resistance heating furnace of the electrolytic reaction pot to melt the sodium chloride and potassium chloride in the electrolytic reaction pot, control the temperature at 745.9°C, feed titanium tetrachloride liquid and argon gas through the feed pipe, and the tetrachloride The purity of the titanium liquid is 99.995%, and the feeding speed is controlled at 28ml / min. Electrolysis is carried out by electrification. The electrolysis process conditions are voltage: 1.9V and current: 400A. After the electrolysis is completed, the cathode link rod is lifted up by the lifting device of the lifting motor, and the meta...

Embodiment 2

[0062] First put sodium chloride and potassium chloride into the electrolytic reaction pot, the molar ratio of sodium chloride and potassium chloride is 1:1; figure 1 The device for producing titanium by molten salt electrolysis shown in the figure is connected, and the vacuum pumped to 5×10 through the vacuum pumping device of the electric reaction pot -1 pa, start the resistance heating furnace of the electrolytic reaction pot to melt the sodium chloride and potassium chloride in the electrolytic reaction pot, control the temperature at 745.9°C, feed titanium tetrachloride liquid and argon gas through the feed pipe, and the tetrachloride The purity of the titanium liquid is 99.995%, and the feeding speed is controlled at 26ml / min. Electrolysis is carried out by electrification. The electrolysis process conditions are voltage: 1.9V and current: 380A. After the electrolysis is completed, the cathode link rod is lifted up by the lifting device of the lifting motor, and the meta...

Embodiment 3

[0064] First put sodium chloride and potassium chloride into the electrolytic reaction pot, the molar ratio of sodium chloride and magnesium chloride is 3:2; figure 1 The device for producing titanium by molten salt electrolysis shown in the figure is connected, and the vacuum pumped to 5×10 through the vacuum pumping device of the electric reaction pot -1 pa, start the resistance heating furnace of the electrolytic reaction pot to melt the sodium chloride and potassium chloride in the electrolytic reaction pot, control the temperature at 510°C, feed titanium tetrachloride liquid and argon gas through the feed pipe, and the tetrachloride The purity of the titanium liquid is 99.995%, and the feeding speed is controlled at 28ml / min. Electrolysis is carried out by electrification. The electrolysis process conditions are voltage: 1.9V and current: 400A. After the electrolysis is completed, the cathode link rod is lifted up by the lifting device of the lifting motor, and the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com