Novel inorganic decoration base material plate and preparation method thereof

A decorative substrate board and inorganic technology, applied in the field of new inorganic decorative substrate board and its preparation, can solve the problems of returning halogen and frost on the surface of the glass magnesium board, shortening the service life of the product, poor waterproofness of the glass magnesium board, etc. Moisture absorption and halogen return, improved fire resistance and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

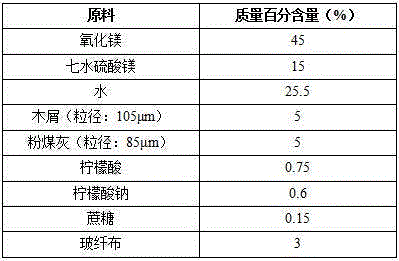

[0051] A new type of inorganic decorative substrate plate, its raw material composition is as follows in Table 1:

[0052] Table 1 The raw material composition of the new inorganic decorative base plate

[0053]

[0054] It has been determined that the water resistance coefficient of the inorganic decorative substrate board is 0.8-0.9, and the mass percentage of chloride ions is 0.012%. Compared with the traditional glass magnesium board, the fireproof performance is enhanced by 10%. , no formaldehyde release.

Embodiment 2

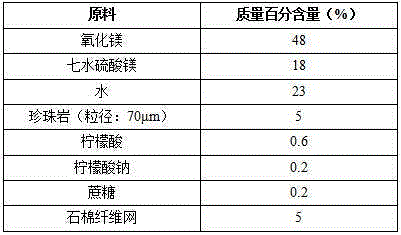

[0056] A new type of inorganic decorative substrate plate, its raw material composition is as follows in Table 2:

[0057] Table 2 The raw material composition of the new inorganic decorative base plate

[0058]

[0059] It has been determined that the water resistance coefficient of the inorganic decorative substrate board is 0.7-0.8, and the mass percentage of chloride ions is 0.010%. Compared with the traditional glass magnesium board, the fire resistance is 8% stronger than the traditional one. The preparation and use process , no formaldehyde release.

Embodiment 3

[0061] A new type of inorganic decorative substrate plate, its raw material composition is as follows in Table 3:

[0062] Table 3 The raw material composition of the new inorganic decorative base plate

[0063]

[0064] It has been determined that the water resistance coefficient of the inorganic decorative substrate board is 0.8-0.9, and the mass percentage of chloride ions is 0.012%. Compared with the traditional glass magnesium board, the fireproof performance is 9% stronger than the traditional one. The preparation and use process , no formaldehyde release.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com