Heating type paper wrapped around non-burning cigarette core material for heating and preparation method of heating type paper

A heating, non-combustion, heating technology, applied in non-woody plant/crop pulp, paper, papermaking, etc., can solve the problems of macula and low heating temperature of cut tobacco, reduce macula, improve paper heat transfer, increase waterproof and moisture resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] As introduced in the background technology, for the peripheral heating type, there are problems such as the lower heating temperature of the cut tobacco, and yellow spots on the paper wrapping the cut tobacco during the storage of cigarettes. Therefore, the present invention proposes a paper wrapping the core material of a heated non-combustible cigarette with peripheral heating and a preparation method thereof, comprising the following steps:

[0031] 1) select natural or regenerated plant fibers and carry out papermaking after a certain degree of pulping;

[0032] 2) Add heat-conducting fillers during the dilution process of the thick slurry after grinding, and the addition ratio of heat-conducting fillers is 30-60% of the mass of the slurry

[0033] 3) Sizing after papermaking to improve the waterproof and moisture-proof properties of the base paper and reduce the possibility of cigarette macula;

[0034] The weight of paper is 20~30g / m 2 ; Paper air permeability i...

Embodiment 1

[0042] Embodiment 1: preparation quantification is 30g / m 2 1. The paper with an air permeability of 20CU for wrapping the core material of non-combustible cigarettes around the periphery. The fiber raw materials, heat-conducting fillers, and surface sizing agents used are shown in Table 1. The particle size of the heat-conducting filler is required to be 2 to 10 microns.

[0043] Table 1

[0044] composition

[0045] Other pulping and papermaking processes are carried out according to the traditional cigarette paper production process.

[0046] The obtained quantitative is 30g / m 2 The paper wrapped around the core material of non-combustible cigarettes was heated with a non-combustible cigarette heater at 300°C and the main smoke aroma components were analyzed. The results are shown in Table 2.

[0047] Table 2

[0048] main aroma ingredient

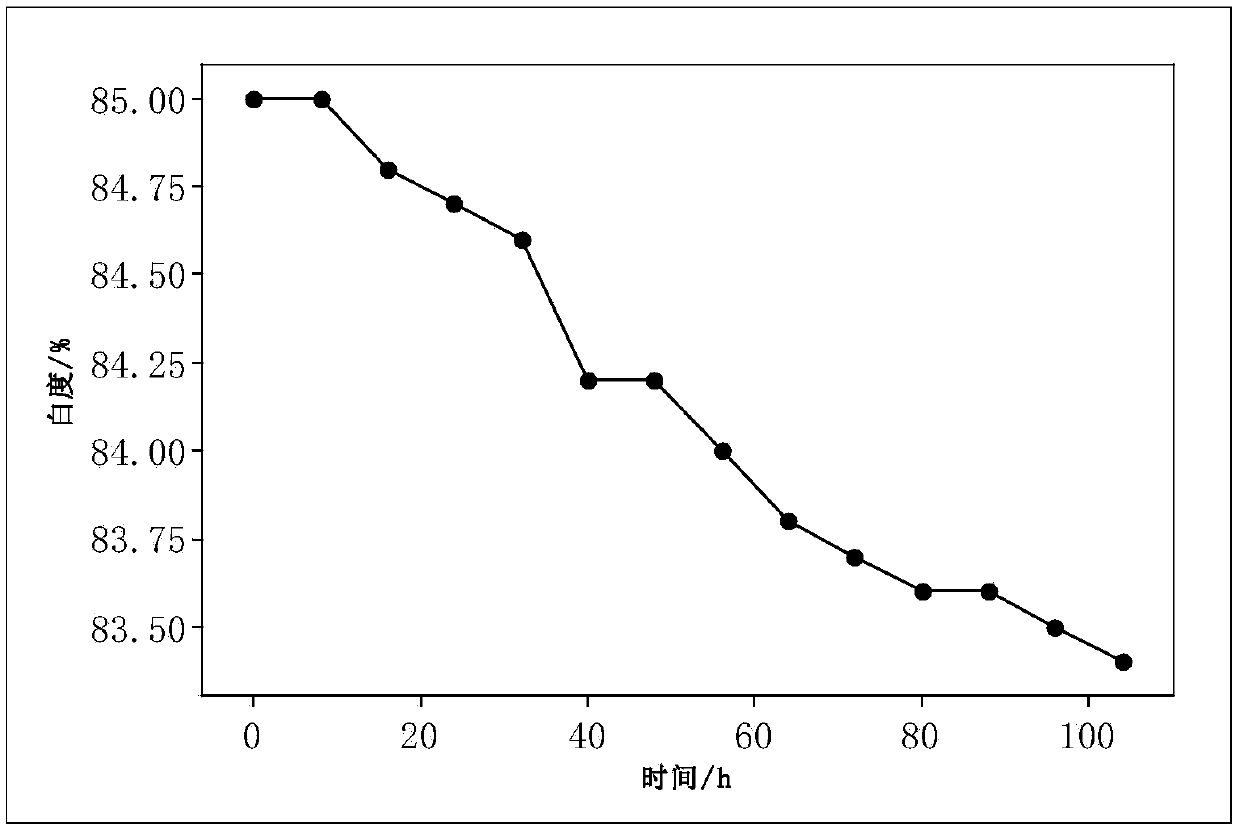

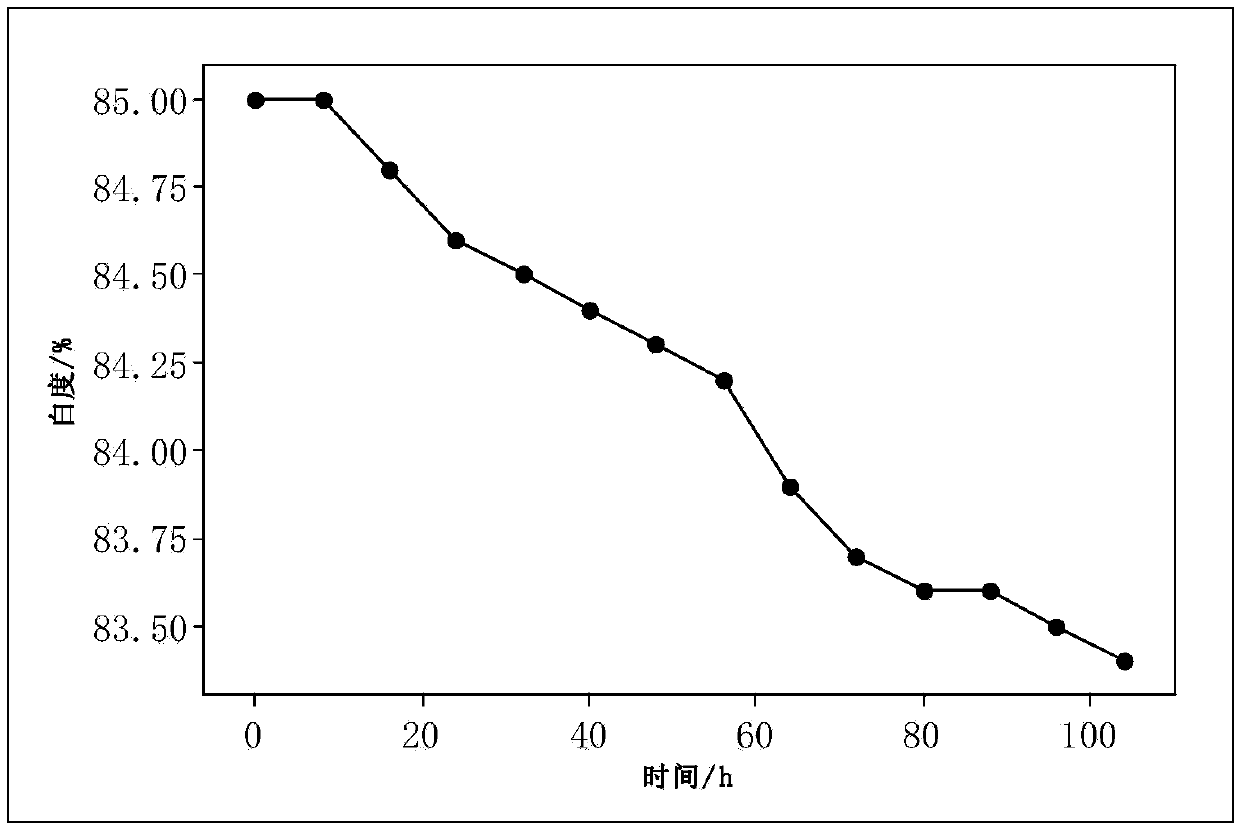

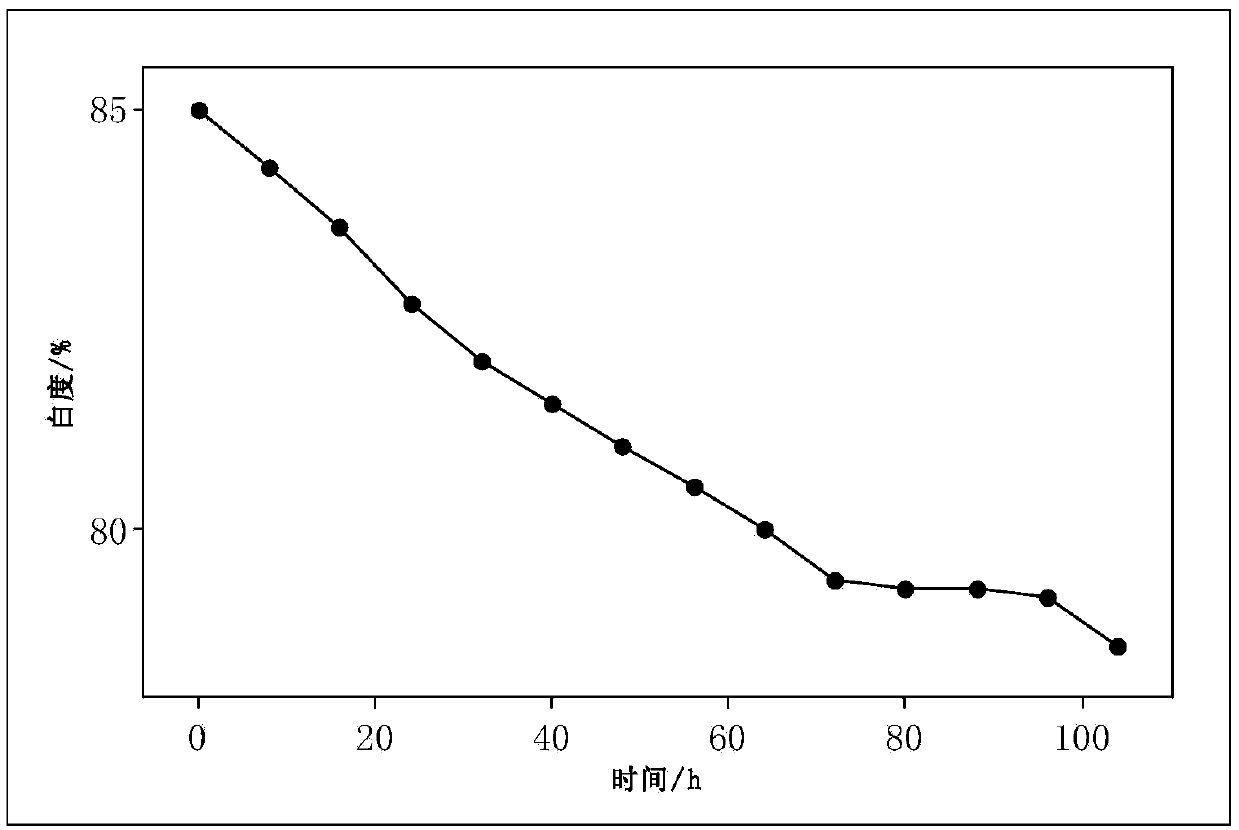

[0049] At the same time, take regular photos of the cigarettes in the storage process, and use software to analy...

Embodiment 2

[0050] Embodiment 2: preparation quantification is 20g / m 21. The paper with an air permeability of 5CU for wrapping the core material of non-combustible cigarettes around the periphery. The fiber raw materials, thermally conductive fillers, and surface sizing agents used are shown in Table 3. The particle size of the thermally conductive filler is required to be 2 to 10 microns.

[0051] table 3

[0052]

[0053]

[0054] Other pulping and papermaking processes are carried out according to the traditional cigarette paper production process.

[0055] The obtained quantitative is 20g / m 2 The paper wrapped around the core material of non-combustible cigarettes was heated with a non-combustible cigarette heater at 300°C and the main smoke aroma components were analyzed. The results are shown in Table 4.

[0056] Table 4

[0057] main aroma ingredient

[0058] At the same time, take regular photos of the cigarettes in the storage process, and use software to anal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com