A kind of carrier tape packaging paper and preparation method

A technology for carrying tape and packaging paper and pulp, applied in pulp beating/refining method, wrapping paper, wrapping paper, etc., can solve the problems of jamming electronic components, troubles of lower-end manufacturers, and achieve high-level bonding strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

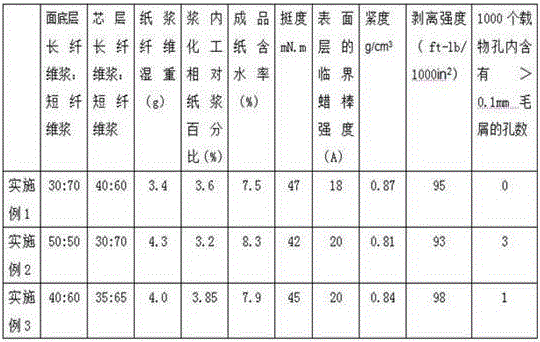

Embodiment 1

[0032] The specific production process is as follows:

[0033] (1) Send the bleached coniferous pulp into the high-consistency pulper for 25-30 minutes for pulping treatment, the pulping concentration is 10-12%, after pulping, put it into the pulp tank to adjust the pulp concentration to 3.5%-4.0 %stand-by;

[0034] (2) Send the slurry treated in step (1) into the double-disk refiner for pulping, and the grinding discs are arranged in the order of cutting first and then fibrillating, and the pulp fibers are disentangled, cut and fibrillated until The beating degree is 35-48°SR, the wet weight is 2.5g-5.0g, and the treated slurry is put into the slurry tank for use;

[0035] (3) Send the bleached broadleaf pulp into the high-consistency pulper for 25-30 minutes for pulping treatment, the pulping concentration is 10-12%, after pulping, put it into the pulp tank to adjust the pulp concentration to 3.5%-4.0 %stand-by;

[0036] (4) Send the slurry treated in step (3) to double-d...

Embodiment 2

[0045] The specific production process is as follows:

[0046] (1) Send the bleached coniferous pulp into the high-consistency pulper for 25-30 minutes for pulping treatment, the pulping concentration is 10-12%, after pulping, put it into the pulp tank to adjust the pulp concentration to 3.5%-4.0 %stand-by;

[0047] (2) Send the slurry treated in step (1) into the double-disk refiner for pulping, and the grinding discs are arranged in the order of cutting first and then fibrillating, and the pulp fibers are disentangled, cut and fibrillated until The beating degree is 35-48°SR, the wet weight is 2.5g-5.0g, and the treated slurry is put into the slurry tank for use;

[0048] (3) Send the bleached broadleaf pulp into the high-consistency pulper for 25-30 minutes for pulping treatment, the pulping concentration is 10-12%, after pulping, put it into the pulp tank to adjust the pulp concentration to 3.5%-4.0 %stand-by;

[0049] (4) Send the slurry treated in step (3) to double-d...

Embodiment 3

[0058] The specific production process is as follows:

[0059] (1) Send the bleached coniferous pulp into the high-consistency pulper for 25-30 minutes for pulping treatment, the pulping concentration is 10-12%, after pulping, put it into the pulp tank to adjust the pulp concentration to 3.5%-4.0 %stand-by;

[0060] (2) Send the slurry treated in step (1) into the double-disk refiner for pulping, and the grinding discs are arranged in the order of cutting first and then fibrillating, and the pulp fibers are disentangled, cut and fibrillated until The beating degree is 35-48°SR, the wet weight is 2.5g-5.0g, and the treated slurry is put into the slurry tank for use;

[0061] (3) Send the bleached broadleaf pulp into the high-consistency pulper for 25-30 minutes for pulping treatment, the pulping concentration is 10-12%, after pulping, put it into the pulp tank to adjust the pulp concentration to 3.5%-4.0 %stand-by;

[0062] (4) Send the slurry treated in step (3) to double-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com