Modified magnesium oxychloride cement product and preparation method thereof

A technology of magnesium oxychloride cement and products, which is applied in the field of preparation of modified magnesium oxychloride cement, which can solve problems such as poor water resistance, abrasive wear, and poor surface finish, and achieve good surface finish, enhanced water resistance, and flexural strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

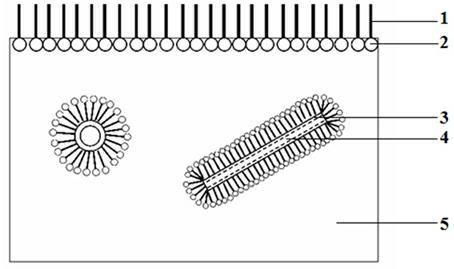

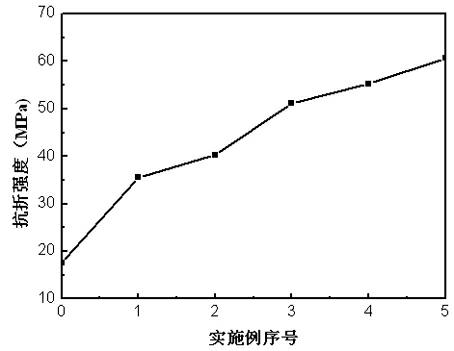

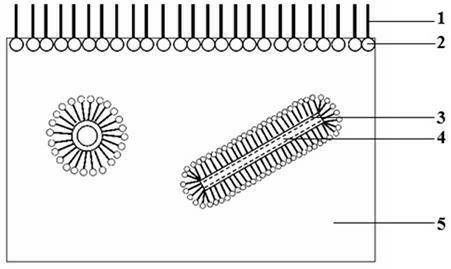

[0026] Modified magnesium oxychloride cement products are composed of the following components and proportions: light burnt magnesium oxide powder (containing 75-95% wt MgO): 100 parts; magnesium chloride (anhydrous MgCl) 2 ): 10 parts; water: 140 parts; calcium carbonate whiskers: 5 parts; silane coupling agent KH-570: 0.05 parts; sodium dodecylbenzene sulfonate: 5 parts.

[0027]

Embodiment 2

[0029] Modified magnesium oxychloride cement products are composed of the following components and proportions: light burnt magnesium oxide powder (containing 75-95% wt MgO): 100 parts; magnesium chloride (anhydrous MgCl) 2 ): 10 parts; water: 140 parts; calcium carbonate whiskers: 10 parts; silane coupling agent KH-570: 0.1 parts; sodium dodecylbenzene sulfonate: 5 parts.

[0030]

Embodiment 3

[0032] Modified magnesium oxychloride cement products are composed of the following components and proportions: light burnt magnesium oxide powder (containing 75-95% wt MgO): 100 parts; magnesium chloride (anhydrous MgCl) 2 ): 10 parts; water: 140 parts; calcium carbonate whiskers: 15 parts; silane coupling agent KH-570: 0.15 parts; sodium dodecylbenzene sulfonate: 5 parts.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com