Fault analog simulation material used for fluid-solid coupling model test and preparation method thereof

A technology of coupled model and similarity simulation, applied in the field of material science, which can solve the problems of rare material ratio of similar faults, rarely considering the water characteristics of materials, and difficult to respond to seepage changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of similar materials for simulating faults in fluid-solid coupling model tests

[0032] The raw materials are as follows: 1 part of quartz sand, 0.12 part of talcum powder, 0.08 part of gypsum powder, 0.09 part of vaseline, and 0.13 part of water.

[0033] The preparation method is:

[0034] 1) Weigh quartz sand, gypsum powder, talcum powder, vaseline and mixing water in strict proportion;

[0035] 2) Mix the three fine-grained materials of quartz sand, gypsum powder and talcum powder and stir evenly;

[0036] 3) Add the weighed mixing water and stir thoroughly;

[0037] 4) Heat the vaseline to 55°C to melt it into a liquid state;

[0038] 5) Mix the liquid petroleum jelly with the material obtained in step 3), and stir well;

[0039] 6) Cool at room temperature for 5 minutes, ready to serve.

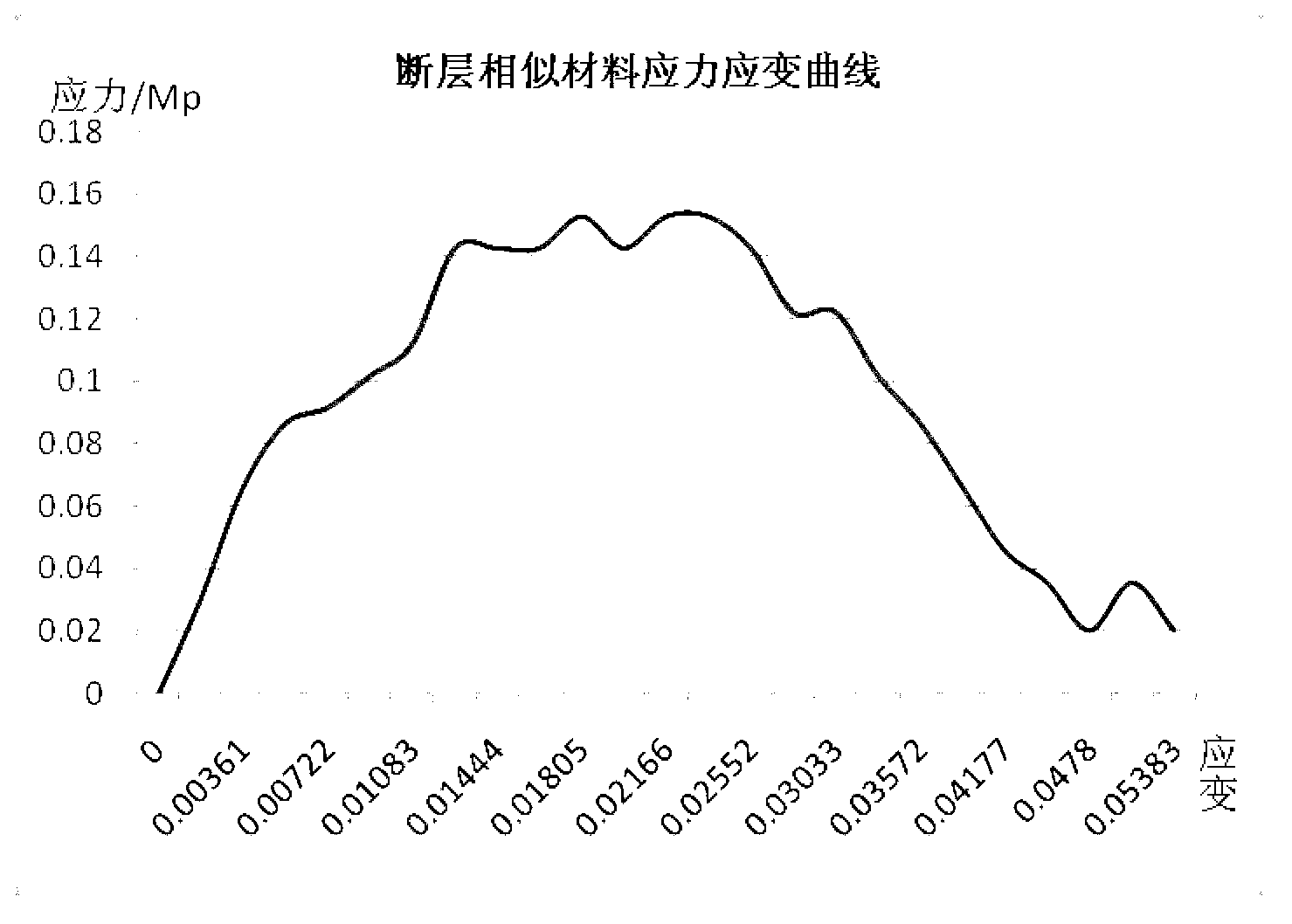

[0040] The stress-strain of the obtained material under uniaxial compressive condition is as follows: figure 1 As shown, it reflects the change proces...

Embodiment 2

[0041] Example 2 Preparation of similar materials for simulating faults in fluid-solid coupling model tests

[0042] The raw material composition is: 1 part of quartz sand, 0.18 part of talcum powder, 0.07 part of gypsum powder, 0.1 part of vaseline, and 0.12 part of water.

[0043] The preparation method is:

[0044] 1) Weigh quartz sand, gypsum powder, talcum powder, vaseline and mixing water in strict proportion;

[0045] 2) Mix the three fine-grained materials of quartz sand, gypsum powder and talcum powder and stir evenly;

[0046] 3) Add the weighed mixing water and stir thoroughly;

[0047] 4) Heat the vaseline to 55°C to melt it into a liquid state;

[0048] 5) Mix the liquid petroleum jelly with the material obtained in step 3), and stir well;

[0049] 6) Cool at room temperature for 5 minutes, ready to serve.

Embodiment 3

[0050] Example 3 Preparation of similar materials for simulating faults in fluid-solid coupling model tests

[0051] The raw materials are as follows: 1 part of quartz sand, 0.08 part of talcum powder, 0.12 part of gypsum powder, 0.13 part of vaseline, and 0.1 part of water. The preparation method is:

[0052] 1) Weigh quartz sand, gypsum powder, talcum powder, vaseline and mixing water in strict proportion;

[0053] 2) Mix the three fine-grained materials of quartz sand, gypsum powder and talcum powder and stir evenly;

[0054] 3) Add the weighed mixing water and stir thoroughly;

[0055] 4) Heat the vaseline to 55°C to melt it into a liquid state;

[0056] 5) Mix the liquid petroleum jelly with the material obtained in step 3), and stir well;

[0057] 6) Cool at room temperature for 5 minutes, ready to serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com