Anti-aging epoxidized natural rubber and preparation method thereof

A technology of natural rubber and epoxidation, which is applied to the field of aging-resistant epoxidized natural rubber and its preparation, can solve the problems of short service life, short storage time, easy aging and the like, and achieves easy large-scale production and simple preparation method. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention provides the preparation method of anti-ageing epoxidized natural rubber described in above-mentioned technical scheme, comprises the following steps:

[0033] (1) under ultrasonic stirring condition, stearate is reacted with surfactant in aqueous phase system, obtains modified stearate dispersion;

[0034] (2) the modified stearate dispersion is mixed with the milky epoxidized natural rubber, and the ultrasonic stirring is continued to obtain the epoxidized natural rubber of the latex state;

[0035] (3) mixing the epoxidized natural rubber in the latex state with a coagulant to obtain the epoxidized natural rubber dry glue;

[0036] (4) Mixing the epoxidized natural rubber dry rubber with rare earth carboxylates and vulcanization processing aids to obtain aging-resistant epoxidized natural rubber.

[0037] In the present invention, under the condition of ultrasonic stirring, the stearate and the surfactant are reacted in the water phase system t...

Embodiment 1

[0044]Add 0.2 parts of calcium stearate to 100 parts of deionized water, control the ultrasonic power to 500W, and add 0.05 parts of sodium dodecylbenzenesulfonate in the state of ultrasonic dispersion, and place it in a water bath at 60°C for continuous Ultrasonic stirring for 4 hours to obtain a modified stearate dispersion, followed by adding 100 parts of epoxidized natural rubber latex with an epoxidation degree of 2 in dry rubber, and continuing ultrasonic stirring for 0.5 hours to obtain epoxidized natural rubber latex in a latex state. Natural rubber; add 0.5 part of methanol to coagulate the epoxidized natural rubber in the milk state, after solidification, go through tableting, granulation, and dry to obtain the epoxidized natural rubber in the dry state, then add 0.2 part on the double-roller open mill Lanthanum oleate and 0.8 parts of sulfur, 2 parts of accelerator NS, 5 parts of zinc oxide and 1 part of stearic acid are mixed and vulcanized to obtain aging-resistant...

Embodiment 2

[0047] Add 1 part of magnesium stearate to 100 parts of deionized water, control the ultrasonic power to 700W, and add 0.08 parts of sodium lauryl sulfate in the state of ultrasonic dispersion, and place it in a water bath at 70°C for 5 hours and continuously stir , to obtain a modified stearate dispersion, then add 100 parts of epoxidized natural rubber latex with a degree of epoxidation of 10 dry rubber, continue ultrasonic stirring for 0.6h, then add 2 parts of ethanol to make the milk state Epoxidized natural rubber is solidified to obtain the epoxidized natural rubber of dry rubber state, then on the two-roll mill, add 0.5 part of cerium stearate and 1 part of sulfur, 1.8 parts of accelerator NS, 4 parts of zinc oxide and 1 part of 100% stearic acid is mixed and vulcanized to obtain anti-aging epoxidized natural rubber.

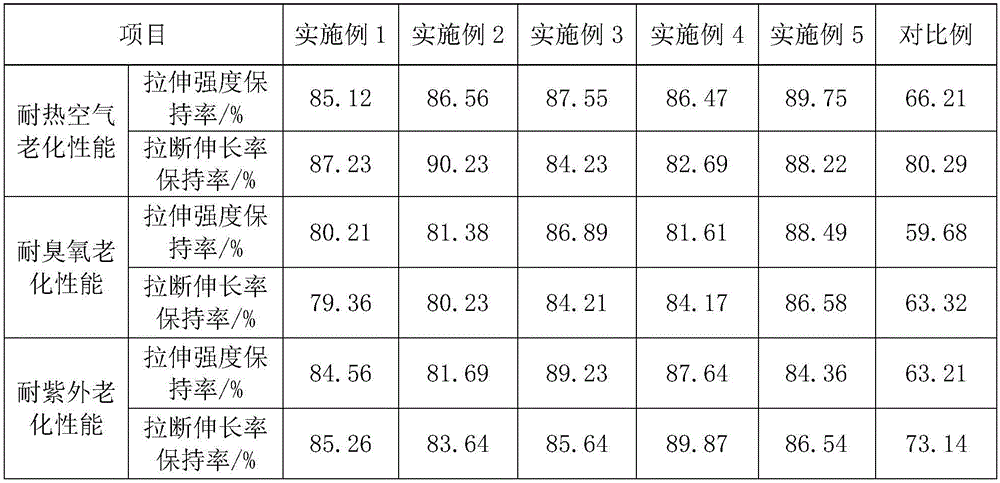

[0048] According to the methods described in GB / T3512-2001, GB / T7762-2003 and GB / T16585-1996, the air aging resistance, ozone aging resistance and ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com