Novel thermosetting ultraviolet stabilizer and preparation method thereof

A UV stabilizer and thermal curing technology, applied in fiber type, textile and papermaking, fiber treatment, etc., can solve the problems affecting the uniformity of spinning solution, poor compatibility, easy to fall off, etc., to achieve adhesion and anti-corrosion Excellent shedding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 2.14g of 4,4'-dihydroxybenzophenone, 1.86g of aniline, 1.21g of paraformaldehyde, and 200mL of xylene into a reaction flask equipped with a stirrer, a thermometer, and a condenser, and raise the temperature Stir mechanically at 100°C, condense and reflux for 4 hours to obtain a brown solution. The cooled brown solution was poured into a separatory funnel, washed three times with 5% sodium hydroxide solution and deionized water respectively, separated the organic layer, and rotated at 80°C for 2 hours, then put it in a vacuum oven Dry at 90°C for 6 hours to obtain 3.39 g of a yellow solid product with a yield of 75.4%. The reaction equation is as follows attached Figure 4 Shown:

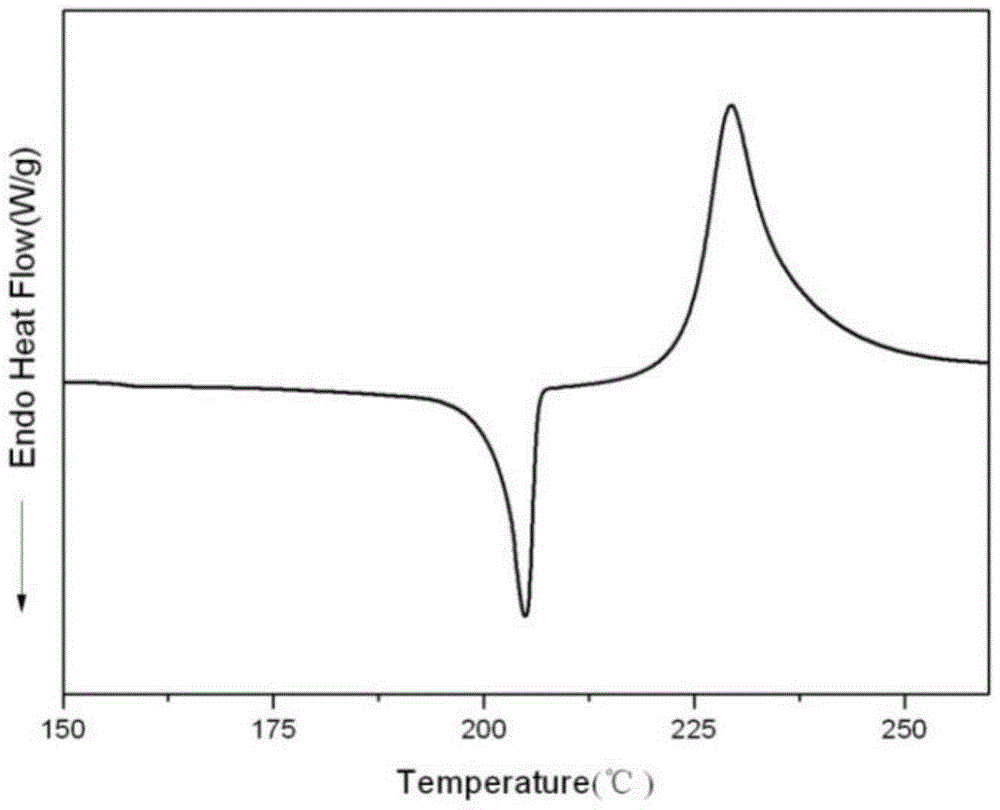

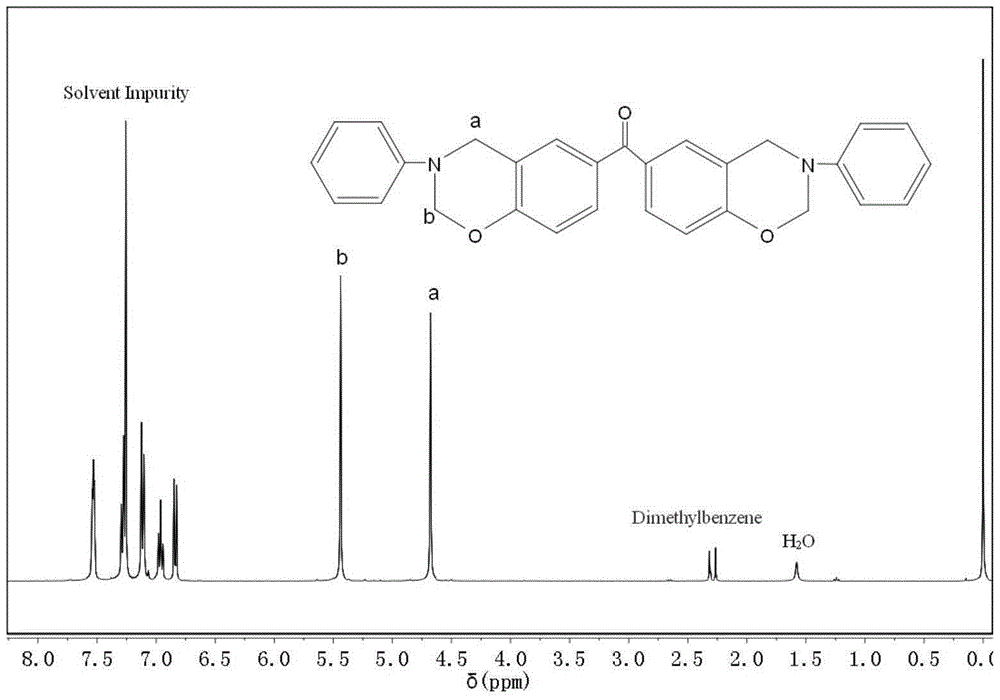

[0030] The characterization results of the product by proton nuclear magnetic spectrum and differential scanning calorimetry (DSC) are shown in attached Figure 5 and attached Image 6 . attached Figure 5 It is the H NMR spectrum, where the shifts at a and b are the char...

Embodiment 2

[0034] The aniline in Example 1 was replaced by p-aminophenylacetylene, and the amount of reactants was changed to: 2.14g of 4,4’-dihydroxybenzophenone, 2.34g of p-aminophenylacetylene, and 1.21g of paraformaldehyde. Except that the amount of the reactant and the thermal curing temperature are changed accordingly, other operating steps are the same as those in Example 1.

[0035] The PBO fiber that this example obtains passes through 1100w / m 2 After 100 hours of ultraviolet light irradiation, the strength retention rate was 78%.

Embodiment 3

[0037] The aniline in Example 1 was replaced by m-aminophenylacetylene, and the amount of reactants was changed to: 2.14g of 4,4'-dihydroxybenzophenone, 2.34g of m-aminophenylacetylene, and 1.21g of paraformaldehyde. Except that the amount of the reactant and the thermal curing temperature are changed accordingly, other operating steps are the same as those in Example 1.

[0038] The PBO fiber that this example obtains passes through 1100w / m 2 After 100 hours of ultraviolet light irradiation, the strength retention rate was 76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com