High-toughness polypropylene/elastomer composite material and preparation method thereof

A technology of composite materials and elastomers, which is applied in the field of high-toughness polypropylene/elastomer composite materials and its preparation, can solve the problems of normal temperature toughness of polypropylene, poor processing performance of polypropylene, and insignificant low-temperature toughening effect, etc. Achieving the effects of low price, excellent low temperature toughness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with embodiment the present invention will be further described:

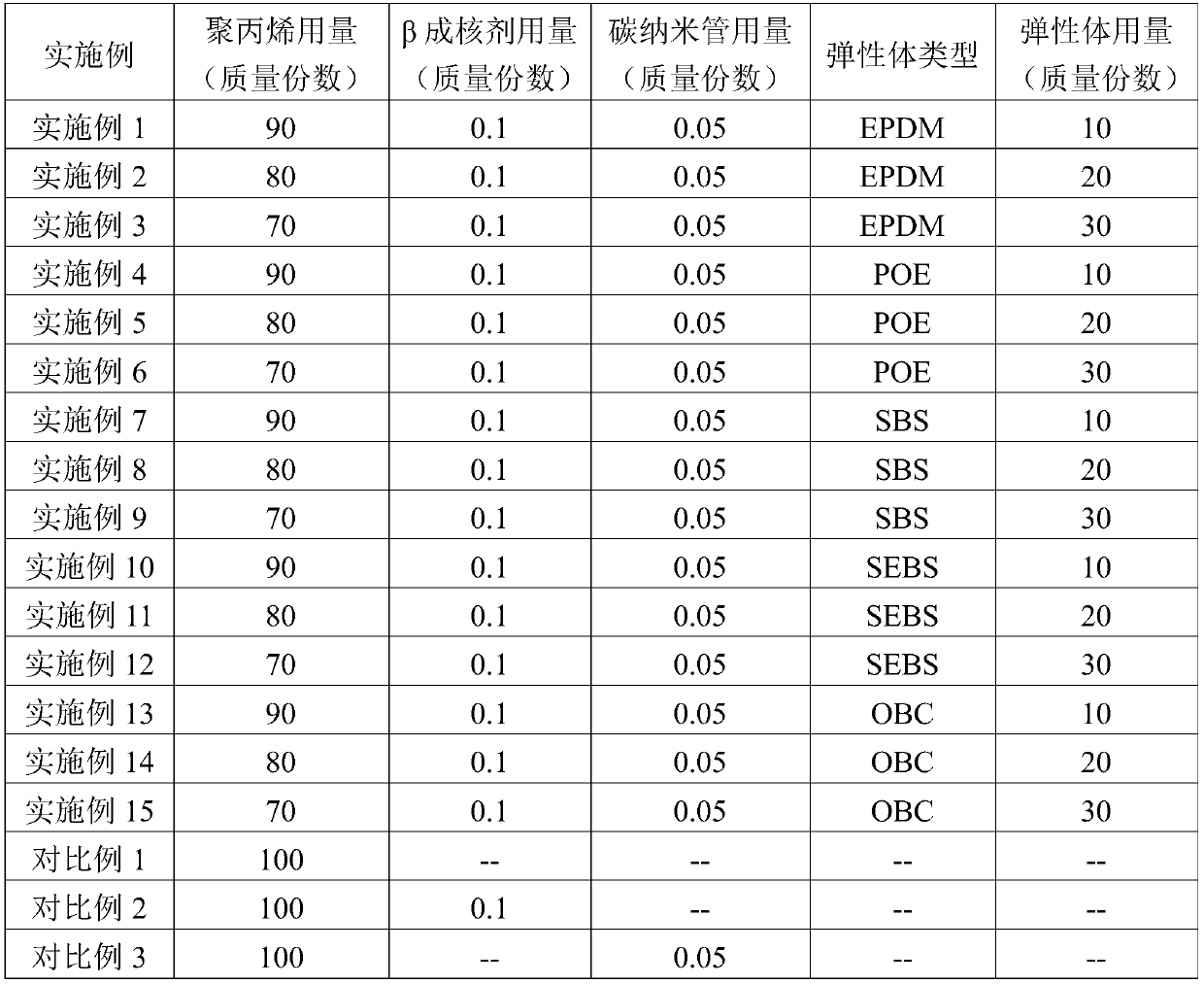

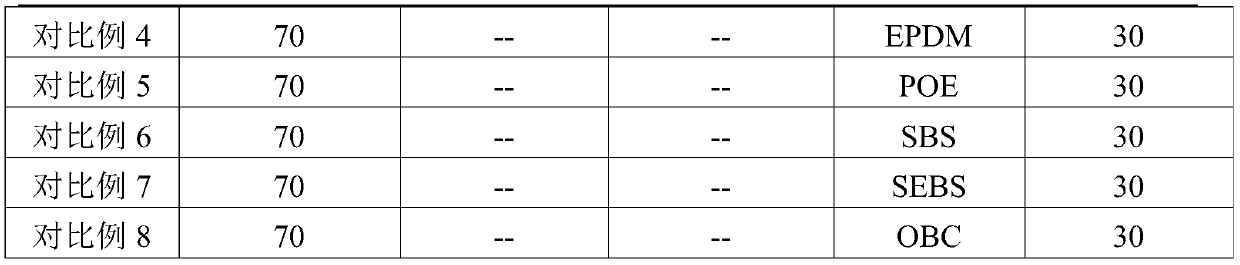

[0025] Table 1 provides the formula tables of 1-15 examples of the present invention, and the formula tables of comparative examples 1-8 of the prior art.

[0026] Table 1 embodiment 1~15 and comparative example 1~8 formula table:

[0027]

[0028]

[0029]The polypropylene is any isotactic polypropylene commercially available.

[0030] The β-nucleating agent is not particularly limited, and may be any commercially available β-nucleating agent.

[0031] The carbon nanotubes can be any commercially available carbon nanotubes.

[0032] The elastomer is EPDM, ethylene-1-octene copolymer elastomer (POE), styrene-butadiene-styrene block copolymer (SBS), styrene-ethylene - any one of butadiene-styrene block copolymer (SEBS), ethylene-octene block copolymer (OBC).

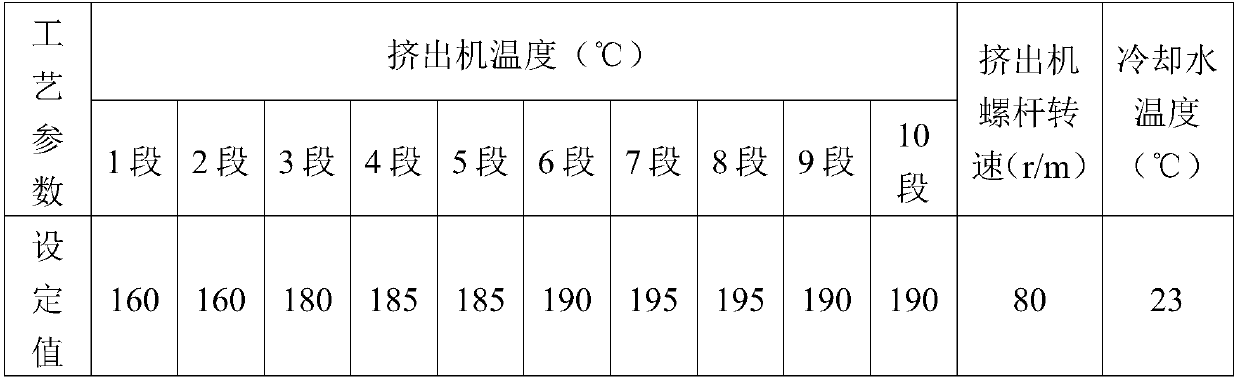

[0033] The preparation process is:

[0034] Step 1: Premix carbon nanotubes, β-nucleating agent, elastomer and polypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com