High-flame retardant property solvent-free polyurethane synthetic leather and preparation method thereof

A solvent-free polyurethane and synthetic leather technology, used in textiles and papermaking, can solve problems such as a large number of toxic fumes and gases, endangering personal and property safety, and polyurethane is not flame-resistant, and achieves good performance, improved wear resistance, and improved The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

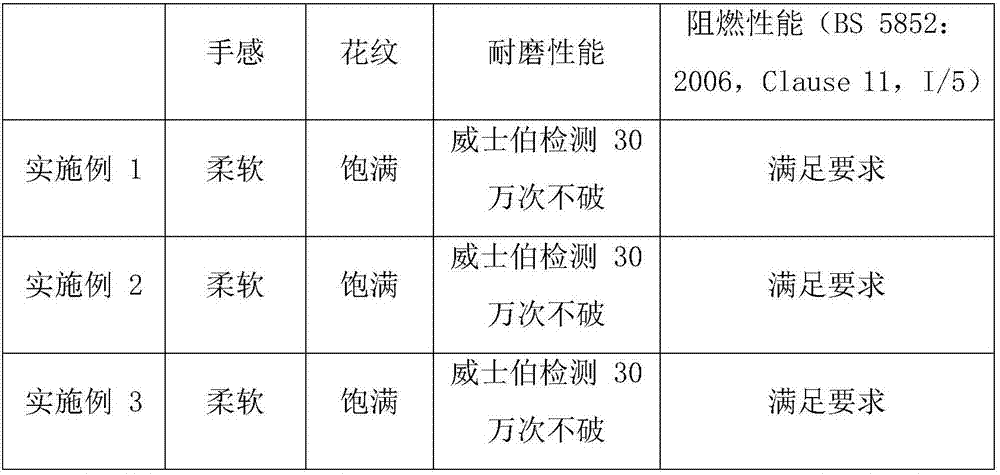

Embodiment 1

[0043] The synthetic leather of this embodiment comprises a four-layer structure of surface layer, middle layer, solvent-free layer and base cloth;

[0044] 120 parts of polyol combination material CC 6945-100 C-A, 30 parts of compound flame retardant (aluminum hydroxide and red phosphorus are 1:0.2 by mass ratio), 0.08 parts of amine catalyst 93600 are mixed to form component A; then Component A is mixed with isocyanate prepolymer CC6945-100 C-B in a mass ratio of 100:40 to form a solvent-free layer slurry.

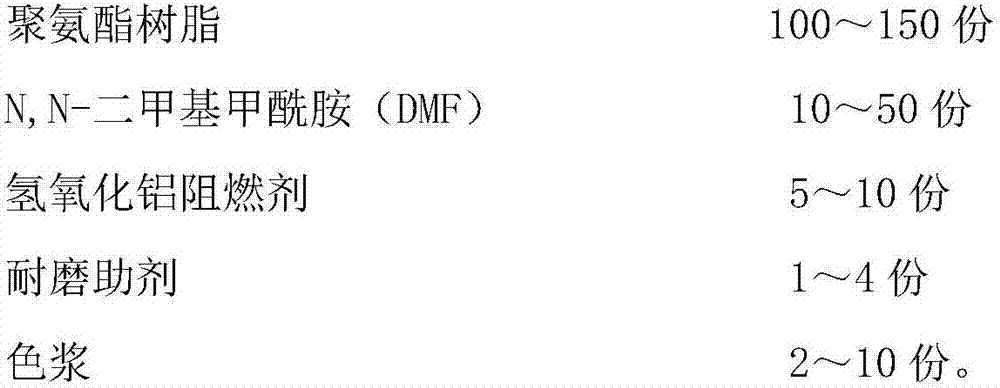

[0045] Mix 120 parts of polyurethane resin LT-80A, 30 parts of N,N-dimethylformamide (DMF), 8 parts of aluminum hydroxide flame retardant, 3 parts of ultra-high molecular weight polysiloxane 3300, and 5 parts of color paste Surface slurry.

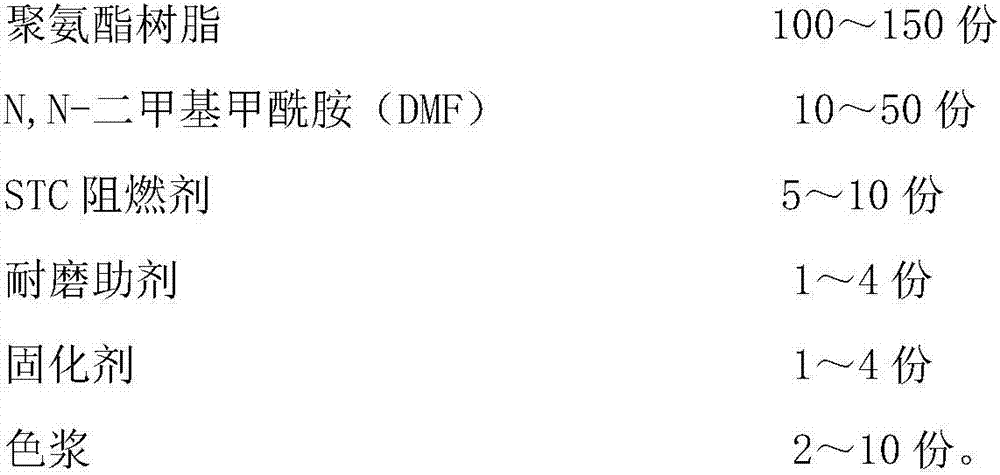

[0046] 120 parts of polyurethane resin ST-8030PC, 30 parts of N,N-dimethylformamide (DMF), 8 parts of STC flame retardant, 3 parts of ultra-high molecular weight polysiloxane 3300, curing agent N-753 parts, Mix 5 parts of color pas...

Embodiment 2

[0053] The synthetic leather of this embodiment comprises a four-layer structure of surface layer, middle layer, solvent-free layer and base cloth;

[0054] Mix 100 parts of polyol composite material CC 6945-100 C-A, 20 parts of compound flame retardant (aluminum hydroxide and red phosphorus are 1:0.4 by mass ratio), 0.05 parts of amine catalyst 93600 to form component A; then Component A is mixed with isocyanate prepolymer CC6945-100 C-B at a mass ratio of 100:45 to form a solvent-free layer slurry.

[0055] Mix 100 parts of polyurethane resin LT-80A, 10 parts of N,N-dimethylformamide (DMF), 5 parts of aluminum hydroxide flame retardant, 4 parts of ultra-high molecular weight polysiloxane 3300, and 10 parts of color paste Surface slurry.

[0056] 100 parts of polyurethane resin ST-8030PC, 10 parts of N,N-dimethylformamide (DMF), 5 parts of STC flame retardant, 1 part of ultra-high molecular weight polysiloxane 3300, curing agent N-methylol compound 1 part and 10 parts of co...

Embodiment 3

[0063] The synthetic leather of this embodiment comprises a four-layer structure of surface layer, middle layer, solvent-free layer and base cloth;

[0064] Mix 110 parts of polyol composite material CC 6945-100 C-A, 40 parts of compound flame retardant (aluminum hydroxide and red phosphorus are 1:0.3 by mass ratio), and 0.1 part of amine catalyst 93600 to form component A; then Component A is mixed with isocyanate prepolymer CC6945-100 C-B at a mass ratio of 100:50 to form a solvent-free layer slurry.

[0065] Mix 150 parts of polyurethane resin LT-80A, 50 parts of N,N-dimethylformamide (DMF), 10 parts of aluminum hydroxide flame retardant, 4 parts of ultra-high molecular weight polysiloxane 3300, and 2 parts of color paste Surface slurry.

[0066] 150 parts of polyurethane resin ST-8030PC, 50 parts of N,N-dimethylformamide (DMF), 10 parts of STC flame retardant, 4 parts of ultra-high molecular weight polysiloxane 3300, curing agent polycarbodiimide 4 2 parts and 2 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com