Environment-friendly fluorine coating for solar battery back plate

A technology for solar cells and fluorine coatings, applied in coatings, circuits, photovoltaic power generation, etc., can solve the problems of inability to balance the weather resistance and adhesion of fluorine coatings, and solve the problems of weather resistance and adhesion, increase weather resistance, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

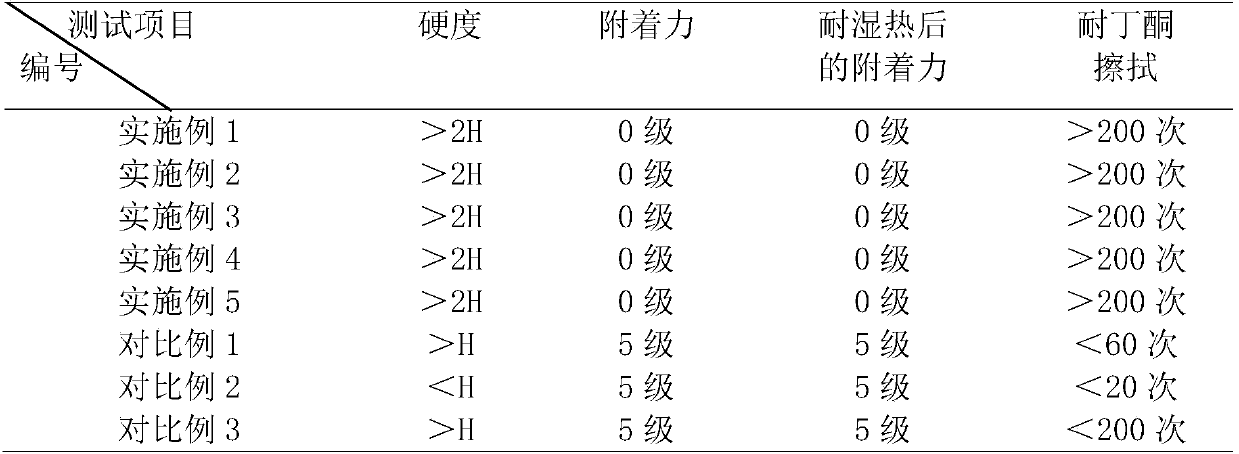

Examples

preparation example Construction

[0027] The preparation method of the aqueous functionalized vinylidene fluoride emulsion is to add fluorine-containing acrylic acid monomer, vinyl monomer, and vinylidene fluoride gas-phase monomer into the autoclave by weight ratio, and add an initiator, such as peroxide Diisopropyl dicarbonate was reacted in ethyl acetate solvent at 40°C for 15 hours, cooled to room temperature to complete the reaction to obtain a functionalized vinylidene fluoride resin, which was added with a neutralizing agent such as triethylamine, deionized The water is stirred and emulsified at a high speed, and finally the solvent ethyl acetate is distilled off under reduced pressure to obtain a water-based functionalized vinylidene fluoride emulsion.

[0028] The fluorine coating provided by the present invention also includes a water-based curing agent, which is one or more selected from hydrophilic aliphatic polyisocyanates, such as Bayer curing agent XP-2700, Kangrui Easaqua XL600, the water-based ...

Embodiment 1

[0034] Aqueous functionalized vinylidene fluoride emulsion, composed of 10g vinylidene fluoride monomer, 20g hexafluoroisopropyl acrylate, 58g ethyl acrylate, 4.2g methyl methacrylate, 1.3g methacrylic acid, 6.5g hydroxymethacrylate Propyl ester monomers are copolymerized, of which vinylidene fluoride monomers account for 10% of the total mass of the resin, the fluorine content is 15%, the hydroxyl value is 25mgKOH / g, the acid value is 8mgKOH / g, and the solid content of the emulsion is 45%.

[0035]Weigh 50g of the above water-based functionalized vinylidene fluoride emulsion, 0.2g of wetting and dispersing agent BYK190, 0.2g of defoamer DC-650.2g, 22.5g of titanium dioxide R706, after high shear dispersion, then weigh 4.4g of curing agent XP-27000 , Bayer, Germany; deionized water 22.5g, leveling agent BYK 3455 0.2g to prepare fluorine coatings.

[0036] Coating the paint on both sides of the PET base material, and drying at 135° C., to obtain a solar battery back sheet.

Embodiment 2

[0038] Aqueous functionalized vinylidene fluoride emulsion, made by copolymerization of 18g vinylidene fluoride, 16g hexafluoroisopropyl acrylate, 50g butyl acrylate, 7.4g methyl methacrylate, 1.4g acrylic acid, 7.2g hydroxybutyl acrylate monomer The vinylidene fluoride monomer content accounts for 18% of the total mass of the resin, the fluorine content is 18%, the hydroxyl value is 28mgKOH / g, the acid value is 9mgKOH / g, and the solid content of the emulsion is 47%.

[0039] Weigh 50g of the above emulsion, 25.8g of titanium dioxide R706, 0.3g of wetting and dispersing agent BYK190, 50.2g of defoamer DC-6, after high shear dispersion, then weigh 5.6g of curing agent XP-2700, Bayer, Germany, deionized Water 17.8g, leveling agent BYK3455 0.3g to prepare fluorine coating.

[0040] The paint is coated on the PET substrate, dried at 135°C, and then the uncoated PET surface is compounded with PE with a polyurethane adhesive to obtain a solar battery back sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com