Tackifier for addition type organosilicon impregnating resin and preparation method thereof

A technology of silicone impregnation and tackifier, applied in the field of silicone polymer materials, can solve the problems of unsatisfactory bonding effect, affecting product transparency, reducing matrix hardness, etc., achieving easy industrial production, excellent heat resistance, The effect of improving adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

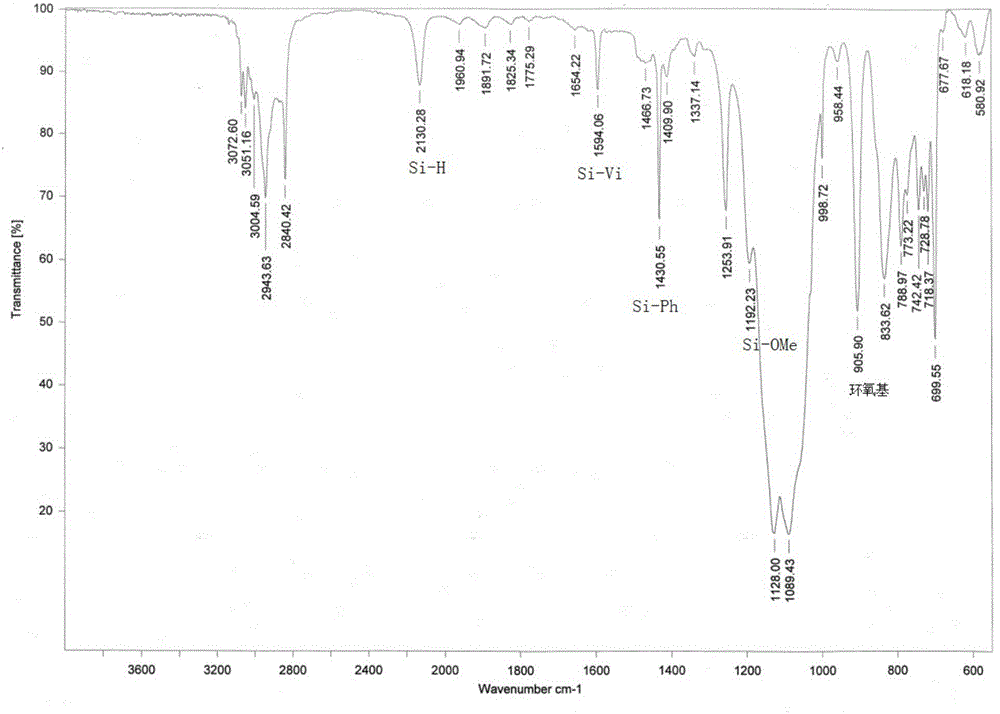

Image

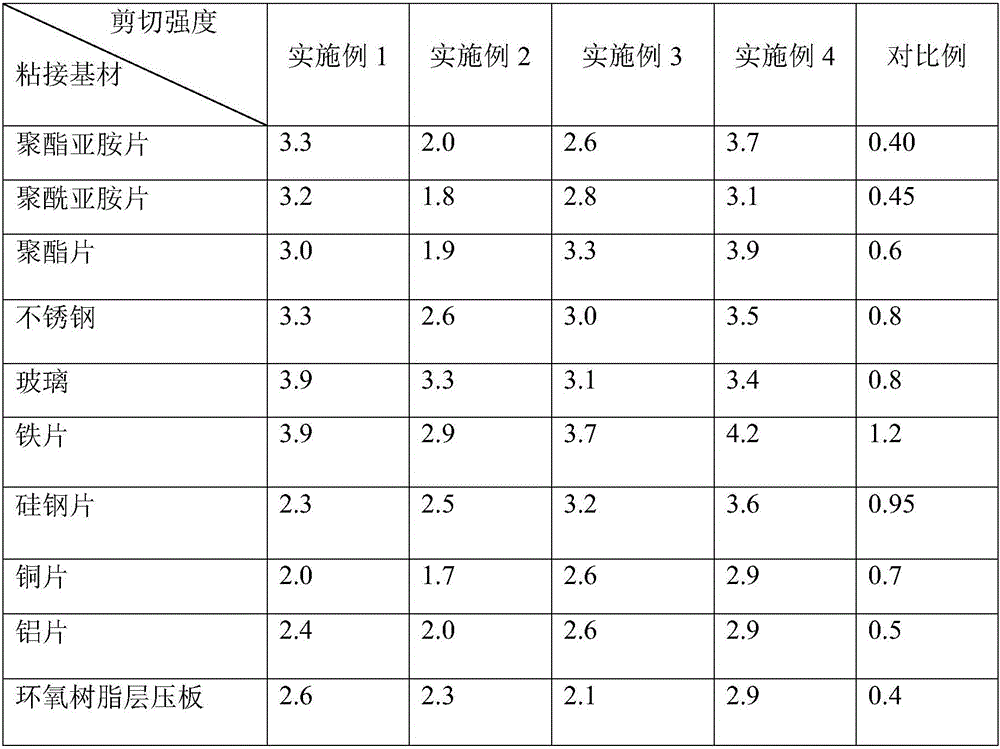

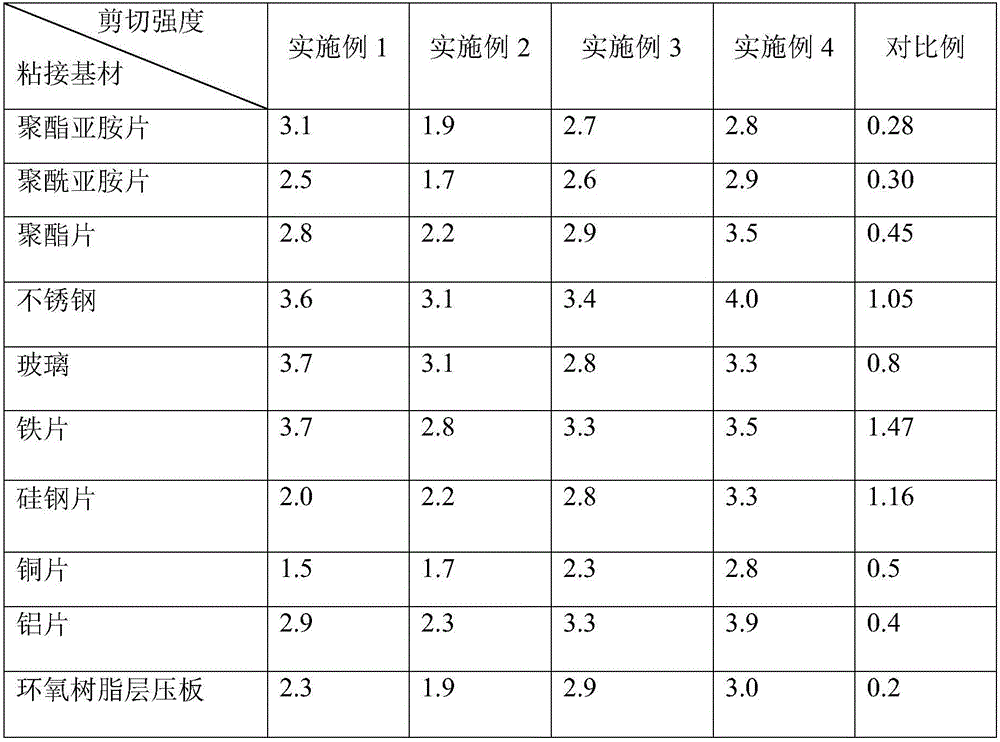

Examples

Embodiment 1

[0025] Add 193 g of water, 145 g of toluene, 65 g of ethyl acetate, and 12 g of 37% concentrated hydrochloric acid into the reaction flask. Weigh 356.2g phenyltrimethoxysilane, 138.46g methylhydrogendimethoxysilane, 7.6g dimethylvinylmethoxysilane, 106.4g methylvinyldimethoxysilane, 22.5g ethylene Trimethoxysilane and 82.7g of γ-glycidoxypropyltrimethoxysilane were evenly mixed and dropped into the reaction bottle, and the temperature of the reaction system was controlled not to be higher than 20°C. After the dropwise addition, react at room temperature for 0.5h, then raise the temperature to reflux, and react at about 75-80°C for 4h; after the reaction, take out the organic layer, wash with water until neutral, add anhydrous calcium chloride to dry for at least 5h, remove the solvent and Small molecules, to obtain the target product.

Embodiment 2

[0027] Add 193g of water, 145g of toluene, 65g of ethyl acetate, and 12g of concentrated hydrochloric acid into the reaction bottle. Weigh 322.3g phenyltrimethoxysilane, 46g methylphenyldimethoxysilane, 138.46g methylhydrogendimethoxysilane, 6.2g dimethylvinylmethoxysilane, 136.85g methyl Vinyldimethoxysilane, 47.2g γ-glycidoxypropyltrimethoxysilane, 37.3g γ-methacryloxypropyltrimethoxysilane were evenly mixed and dropped into the reaction bottle, and the temperature of the reaction system was controlled. higher than 20°C. After the dropwise addition, react at room temperature for 1 hour, then raise the temperature to 80-85°C for reflux reaction for 4 hours; take out the organic layer after the reaction, wash with water until neutral, add anhydrous calcium chloride to dry for at least 5 hours, remove the solvent and small molecules under reduced pressure, Obtain the target product.

Embodiment 3

[0029] Add 193g, 145g of toluene, 65g of ethyl acetate, and 1.5g of trifluoromethanesulfonic acid into the reaction bottle. Weigh 356.2g phenyltrimethoxysilane, 138.46g methylhydrogendimethoxysilane, 6.2g dimethylvinylmethoxysilane, 136.85g methylvinyldimethoxysilane, 42.5gγ- Glycidoxypropyltrimethoxysilane and 34.88g of 3-isocyanatopropyltrimethoxysilane were evenly mixed and dropped into the reaction bottle, and the temperature of the reaction system was controlled not to be higher than 20°C. After the dropwise addition, react at room temperature for 0.5h, then raise the temperature to 75-80°C for reflux reaction for 4h; after the reaction, take out the organic layer, wash with water until neutral, add anhydrous calcium chloride to dry for at least 5h, remove the solvent and small molecules under reduced pressure , to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com