Paint for solar cell backsheet

A technology for solar cells and coatings, applied in coatings, circuits, electrical components, etc., can solve the problems of poor heat resistance, lamination appearance with texture, low coating hardness, etc., to improve weather resistance and reduce production costs. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the vinylidene fluoride polymer is that the gas-phase monomer of vinylidene fluoride is mixed with vinyl fluoride, hexafluoropropylene, tetrafluoroethylene, chlorotrifluoroethylene, trifluoroethylene, hexafluoroisobutylene, perfluorobutylethylene, One or more of the gas-phase monomers such as perfluorovinyl ether are pressed into the high-pressure reactor according to the weight ratio, the reactor is opened, and the reaction is carried out at 80°C for 3 hours, and the material is discharged after cooling to obtain partial Samples of vinyl fluoride copolymers.

[0032] The fluorine-containing acrylic resin is formed by copolymerizing acrylate monomers, hydroxyl-containing acrylate monomers and fluorine-containing acrylate monomers.

[0033] The acrylate monomer is selected from methyl methacrylate, methyl acrylate, ethyl methacrylate, ethyl acrylate, propyl methacrylate, propyl acrylate, methacrylic acid having good compatibility with vinylidene...

Embodiment 1

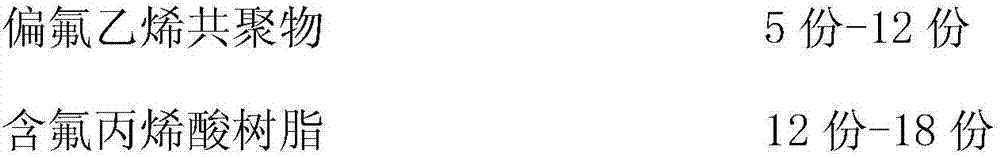

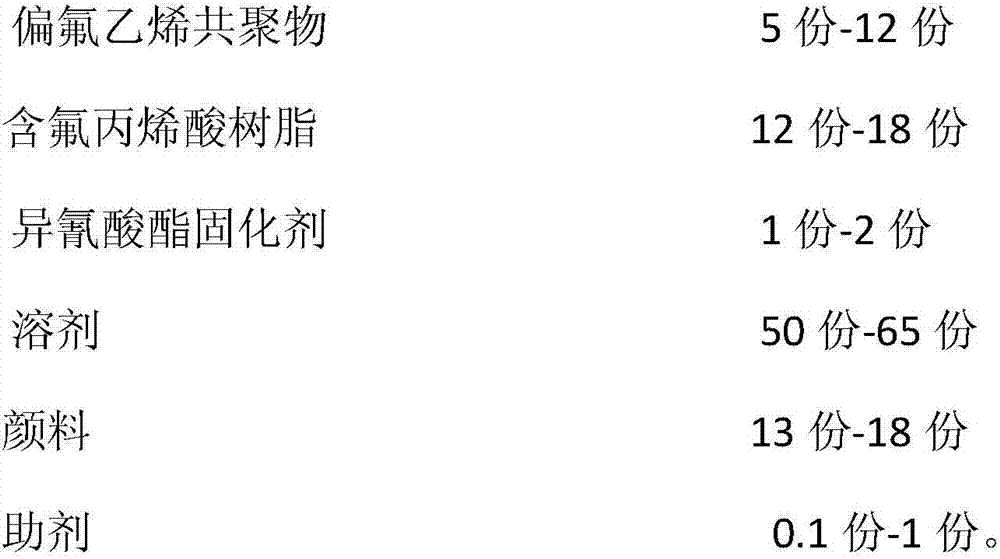

[0051] Paint Composition:

[0052] Vinylidene fluoride and hexafluoropropylene copolymer (vinylidene fluoride content 95%, melting point 158°C, molecular weight 150,000) 5g, fluorine-containing acrylic resin (fluorine-containing acrylic monomer content 8%, molecular weight 15,000) 16g, HDI 1.4g , 13g of titanium dioxide, 0.1g each of defoamer and dispersant, 64.4g of mixed solvent of butyl acetate, isoflurane, and nitrogen-nitrogen dimethylformamide.

[0053] Coating the paint on the PET substrate, drying at 180°C, and then compounding the uncoated PET surface with a polyurethane adhesive and PE to obtain a solar battery back sheet.

Embodiment 2

[0055] Paint Composition:

[0056] Copolymer of vinylidene fluoride and tetrafluoroethylene (vinylidene fluoride content 88%, melting point 150°C, molecular weight 300,000) 10g, fluorine-containing acrylic resin (fluorine-containing acrylic monomer content 14%, molecular weight 10,000) 15g, IPDI 1.9 g: 16g of titanium dioxide, 0.1g each of defoamer and dispersant, 57.2g of butyl acetate, isoflurane, and nitrogen-nitrogen dimethylacetamide.

[0057] Coating the paint on both sides of the PET base material, and drying at 180° C., to obtain a solar battery back sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com