High-temperature self-crosslinking anti-flaming anti-dripping copolyester based on Schiff base structure and preparation method thereof

A Schiff base, self-crosslinking technology, applied in the high temperature self-crosslinking flame retardant anti-droplet copolyester and its preparation field, can solve the problem of limited application scope, large addition amount, polyester can not be spun and processed into Film and other problems, to achieve the effect of improving melt viscosity, reducing preparation cost, excellent flame retardant and anti-droplet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

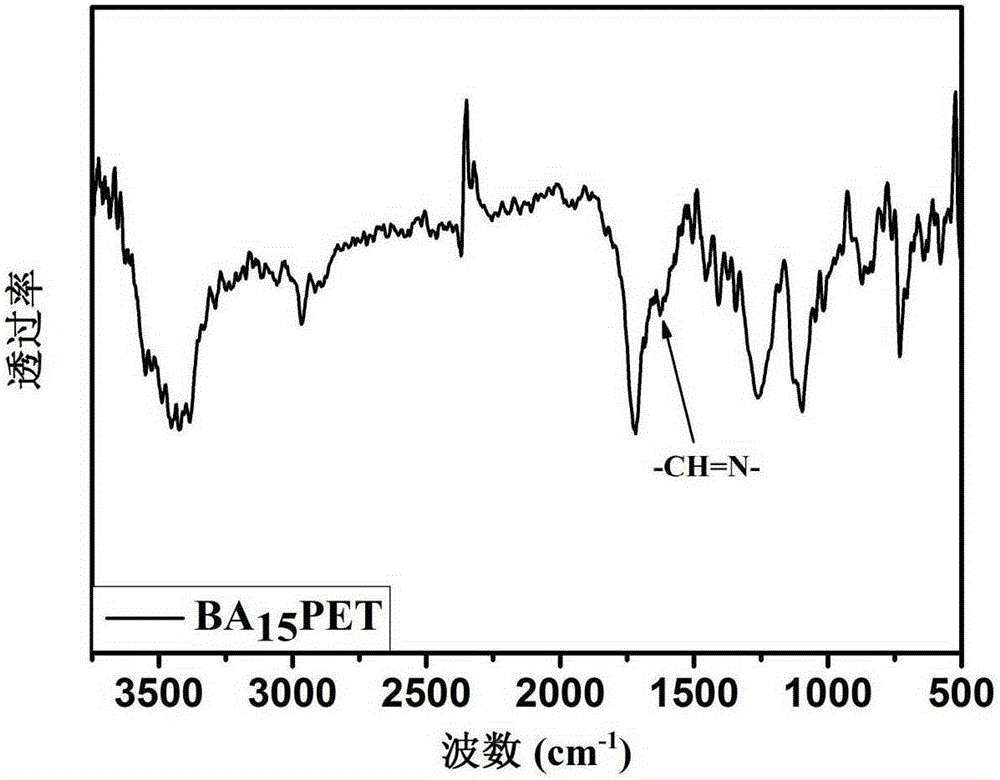

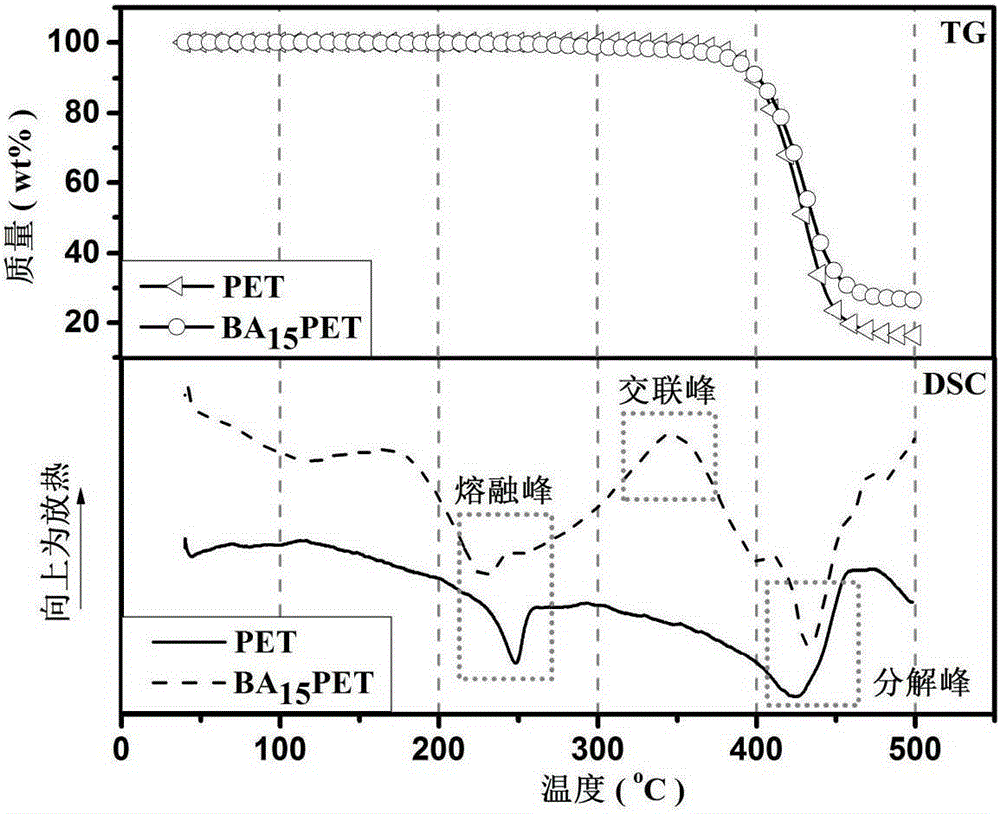

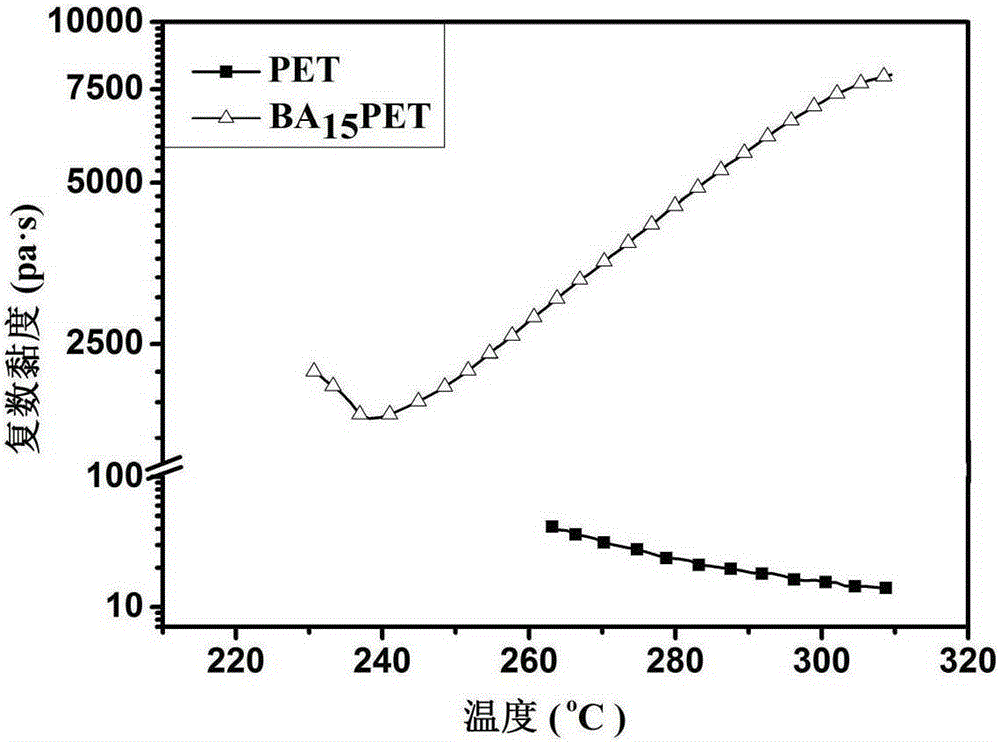

Method used

Image

Examples

Embodiment 1

[0044] 388g dimethyl terephthalate, 210mL ethylene glycol, 18.1g 4-(2-hydroxyethoxy) benzaldehyde acetal 4-(2-hydroxyethoxy) aniline Schiff base, 2.2g zinc acetate and 0.16 g tetrabutyl titanate was added to the reaction kettle, filled with nitrogen to remove the air in the kettle, and carried out the transesterification reaction at 180-210°C under normal pressure for 3-5 hours; ~ 1.5 hours, and then under high vacuum (pressure <60Pa) at 230 ~ 260 ° C for 1 ~ 3 hours after polycondensation, discharge, water cooling.

[0045] The intrinsic viscosity [η] of the copolyester is 0.71dL / g; the limiting oxygen index is 25.5%; the vertical combustion rating is V-2, and the peak heat release rate p-HRR in the cone calorimetry test is 704kW / m 2 .

Embodiment 2

[0047] 388g dimethyl terephthalate, 210mL ethylene glycol, 30.1g 4-(2-hydroxyethoxy) benzaldehyde acetal 4-(2-hydroxyethoxy) aniline Schiff base, 2.2g zinc acetate and 0.16 g of tetrabutyl titanate was added to the reaction kettle, and after the transesterification and polycondensation reactions were carried out according to the steps and conditions given in Example 1, the material was discharged.

[0048] The intrinsic viscosity [η] of the copolyester is 0.66dL / g; the limiting oxygen index is 28.0%; the vertical combustion rating is V-1, and the peak heat release rate p-HRR in the cone calorimetry test is 624kW / m 2 .

Embodiment 3

[0050] 388g dimethyl terephthalate, 210mL ethylene glycol, 60.2g 4-(2-hydroxyethoxy) benzaldehyde acetal 4-(2-hydroxyethoxy) aniline Schiff base, 2.2g zinc acetate and 0.16 g antimony trioxide was added to the reaction kettle, and after transesterification and polycondensation were carried out according to the steps and conditions given in Example 1, the material was discharged.

[0051] The intrinsic viscosity [η] of the copolyester is 0.67dL / g; the limiting oxygen index is 29.5%; the vertical combustion rating is V-1, and the peak heat release rate p-HRR in the cone calorimetry test is 546kW / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com