Polyurethane elastomer composition of paraffin wax aggregate thickened by solid nano particles and preparation method thereof

A technology of polyurethane elastomer and polyurethane prepolymer, which is applied in the field of polyurethane elastomer composition, can solve the problems of paraffin wax flowing and melting at high temperature, and achieve the effects of reducing migration and precipitation, good compatibility, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

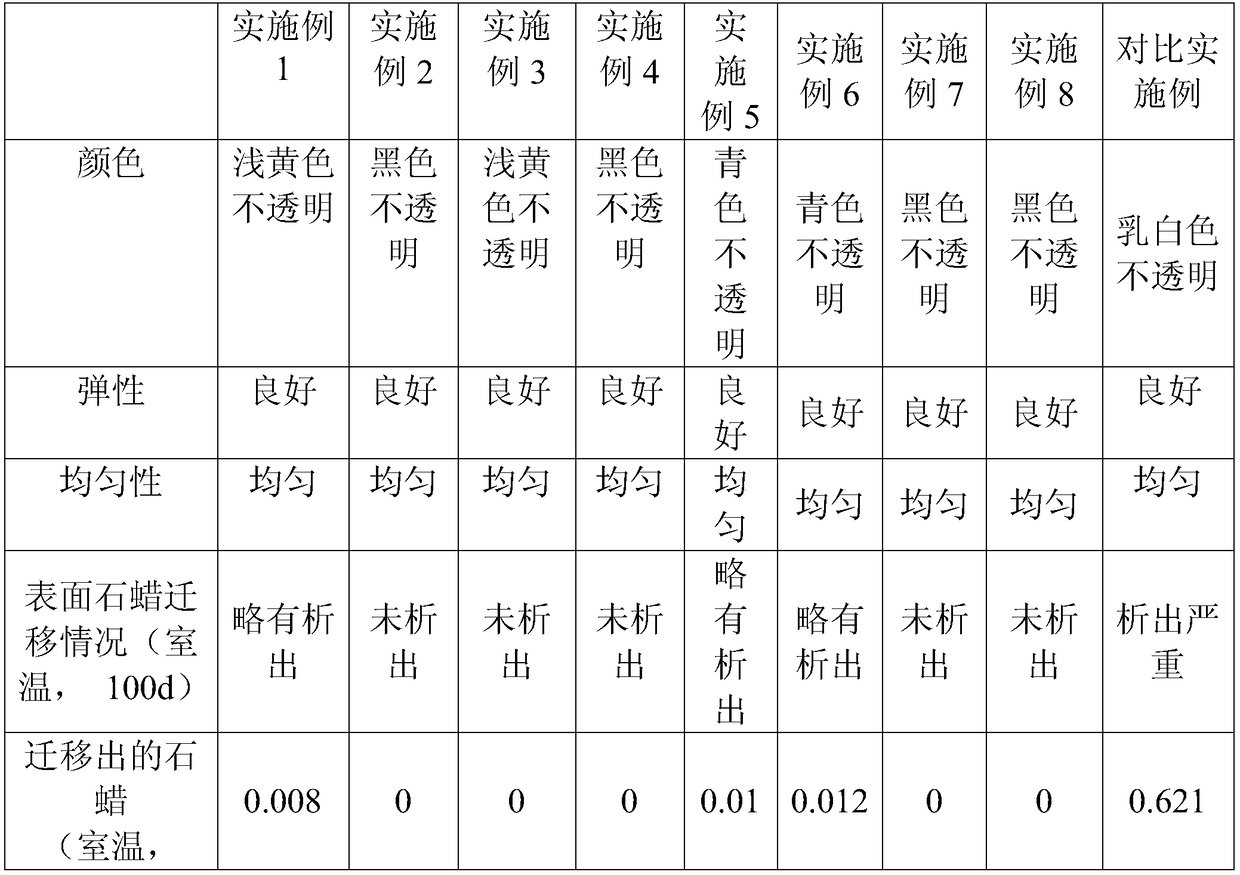

Examples

Embodiment 1

[0033] Heat 76.5g of 50# paraffin to 100°C and stir for 10 minutes to dissolve it completely. Add 13.5g of nano-silicon nitride into the paraffin wax system under high-speed stirring conditions (500 rpm), continue to stir at 100°C for 20min, then raise the temperature to 180°C, refine at high temperature for 1.5h, stop heating, and let it stand to cool to At room temperature, a paraffin aggregate thickened with nano-silicon nitride particles is obtained.

[0034] Weigh 16g of hydroxyl-terminated polybutadiene HTPB and 8g of plasticizer dioctyl sebacate (DOS), stir evenly at 78°C, add 1.5g of toluene diisocyanate (TDI), stir evenly and react for 10min, Add 5.5g of nano-silicon nitride thickened paraffin aggregates (solid nano-particle thickener content 15%, paraffin: lubricating oil base oil is 1:0) that has been preheated to 60 ℃ therein, continue stirring reaction 20min , under the condition of vacuum degree of 400Pa, defoam under reduced pressure for 6min; then raise the te...

Embodiment 2

[0036] Heat 38.5g of 50# paraffin and 38.5g of base oil 150BSM to 80°C, add 4.5g of structure stabilizer diphenylsilanediol to it, stir for 10min to dissolve completely. Add 15.0g of nano-silicon nitride into the paraffin wax system under high-speed stirring conditions (500 rpm), stir evenly and heat up to 120°C, add 3.5g of expanded graphite, stir for 40min, then heat up to 220°C, and refine at high temperature After 2.5 hours, the heating was stopped, and the mixture was left to cool down to room temperature to obtain paraffin aggregates thickened with nano-silicon nitride particles.

[0037] Weigh 16.5g of hydroxyl-terminated polybutadiene HTPB and 9g of plasticizer dioctyl sebacate (DOS), stir evenly at 85°C, add 2.0g of toluene diisocyanate (TDI), and then add 1 drop of diisocyanate Dibutyltin laurate (DBTL) stirs and reacts 10min, adds the paraffin aggregate (18.5% of solid nano particle thickener content of thickening agent content 18.5%, paraffin:lubricating oil The b...

Embodiment 3

[0039] Heat 87.0g of 50# paraffin to 100°C and stir for 10 minutes to dissolve it completely. Add 13.0g of nano-silica to the paraffin wax system under high-speed stirring conditions (600 rpm), stir evenly and raise the temperature to 120°C and stir for 30min, then raise the temperature to 200°C, refine at high temperature for 1.5h, stop heating, and stand Cool to room temperature to obtain paraffin aggregates thickened by nano-silica particles.

[0040] Weigh 17.0g hydroxyl-terminated polybutadiene HTPB and 8.5g plasticizer dioctyl sebacate (DOS), stir evenly at 80°C, add 1.8g toluene diisocyanate (TDI) to it, stir evenly and react 10min, add the paraffin aggregate (13% of solid nano particle thickener content, paraffin:lubricating oil base oil is 1:0) of 6g nano silicon dioxide thickening that has been preheated to 80 ℃ therein, continue stirring reaction For 20 minutes, under the condition of vacuum degree of 200Pa, decompress and defoam for 4 minutes; then raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com