Digital control machine tool positioning error real-time compensation device

A technology of numerical control machine tools and positioning errors, applied in the direction of program control, computer control, general control systems, etc., can solve the problems of not reaching the level of commercialization, not universal, complex application and implementation, etc., and achieve flexible and universal software modification Strong, hardware-simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

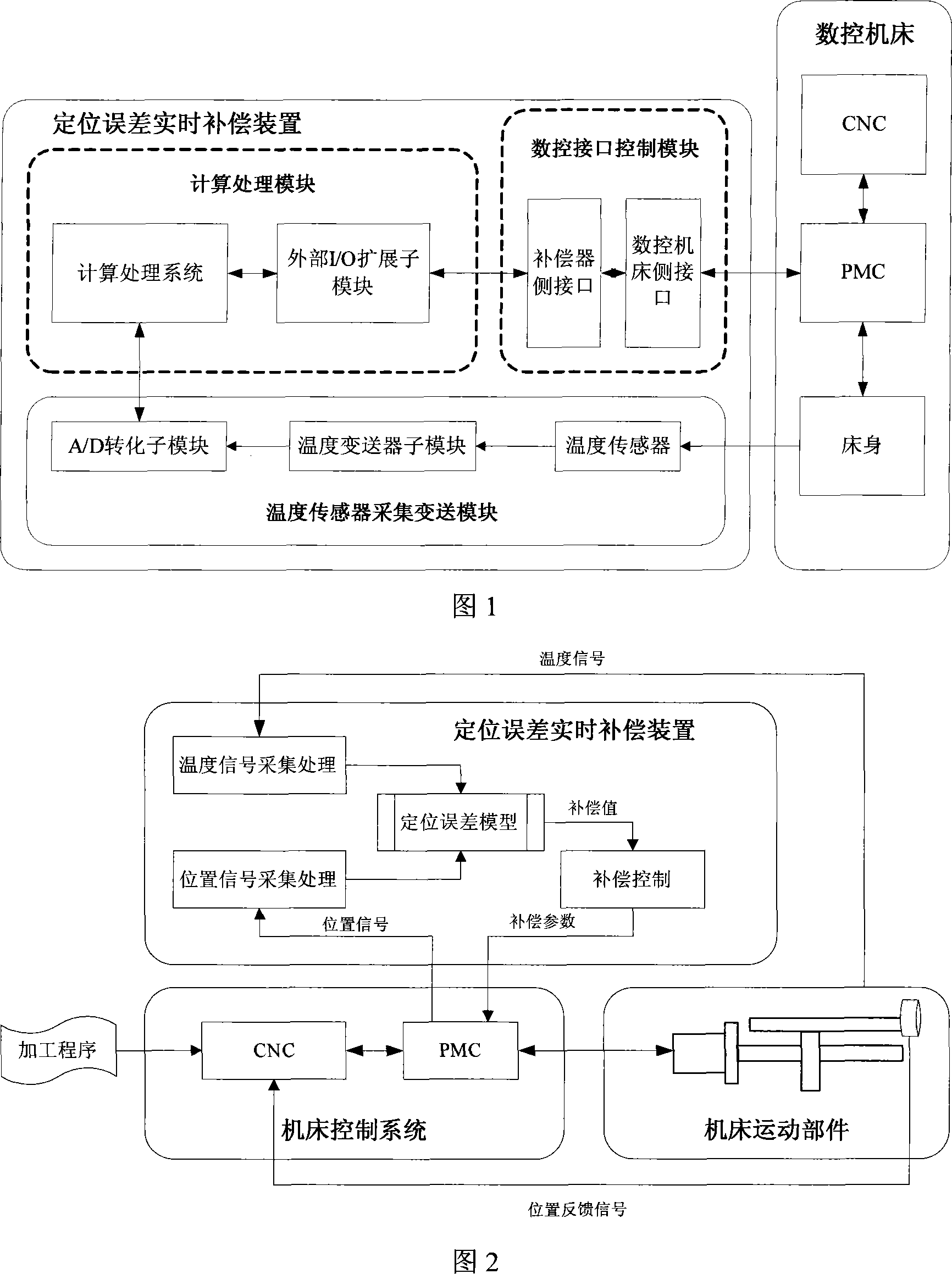

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The structure of the device of the present invention is shown in Figure 1, which is composed of a calculation processing module, a temperature sensor acquisition and transmission module, and a numerical control interface control module. The calculation processing module includes the calculation processing system and external I / O expansion sub-module; the temperature sensor acquisition and transmission module includes the A / D conversion sub-module, the temperature transmitter sub-module and several temperature sensors; the numerical control interface control module can include the compensator side interface and CNC machine side interface.

[0018] In the calculation processing module, the calculation processing system is connected to the A / D conversion sub-module in the temperature sensor acquisition and transmission module through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com