Double eccentric circle mechanism with adjustable transmission shaft center position

A technology of center position and eccentric circle, which is applied in the mechanical field of adjusting the installation position of the axis (center), can solve the problems of vibration of the transmission device, reduce the machining accuracy, shorten the life and other problems, achieve simple action, and promote the improvement and adjustment of the design accuracy. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

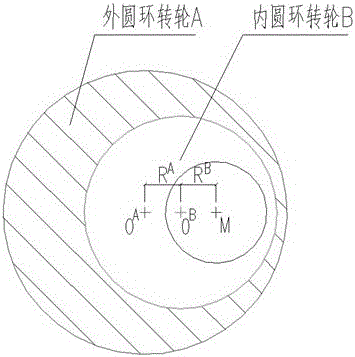

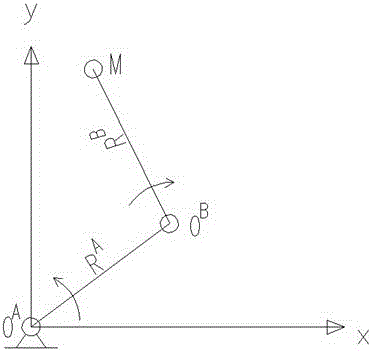

[0056] The sun—the rocker in the planetary gear train is replaced with two eccentric rings, namely the outer ring runner A and the inner ring runner B. Such as figure 1 , 2 shown.

[0057] The outer ring runner A is composed of an outer circle and an inner circle, and its outer circle center is the center of the sun wheel axis O A , its inner center is the axis O of the planetary wheel B , O A with O B The distance between is the outer ring eccentricity R A .

[0058] Inner ring runner B is also an eccentric ring. The center of its outer circle coincides with the center of the inner circle of the outer ring runner A, which is O B . Its inner circle center M is the center of the target axis, O B The distance from M is the inner ring eccentricity R B .

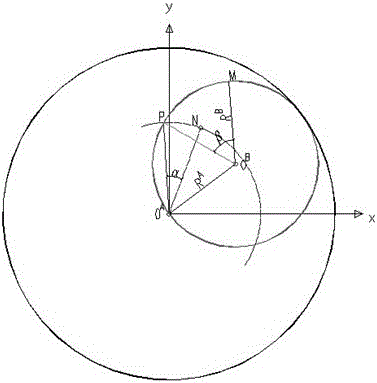

[0059] Order R A =R B , then the trajectory of the target axis axis M can be covered by O A as the center of the circle, with R A +R B is the circular area with radius, that is, M can reach any point within this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com