Steel strip punching processing detection system and method based on vision measurement

A technology of visual measurement and detection method, applied in the field of detection, can solve problems such as punching detection of steel strips with a wider size, and achieve the effects of improving motion accuracy, facilitating surface image processing, and simplifying image processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

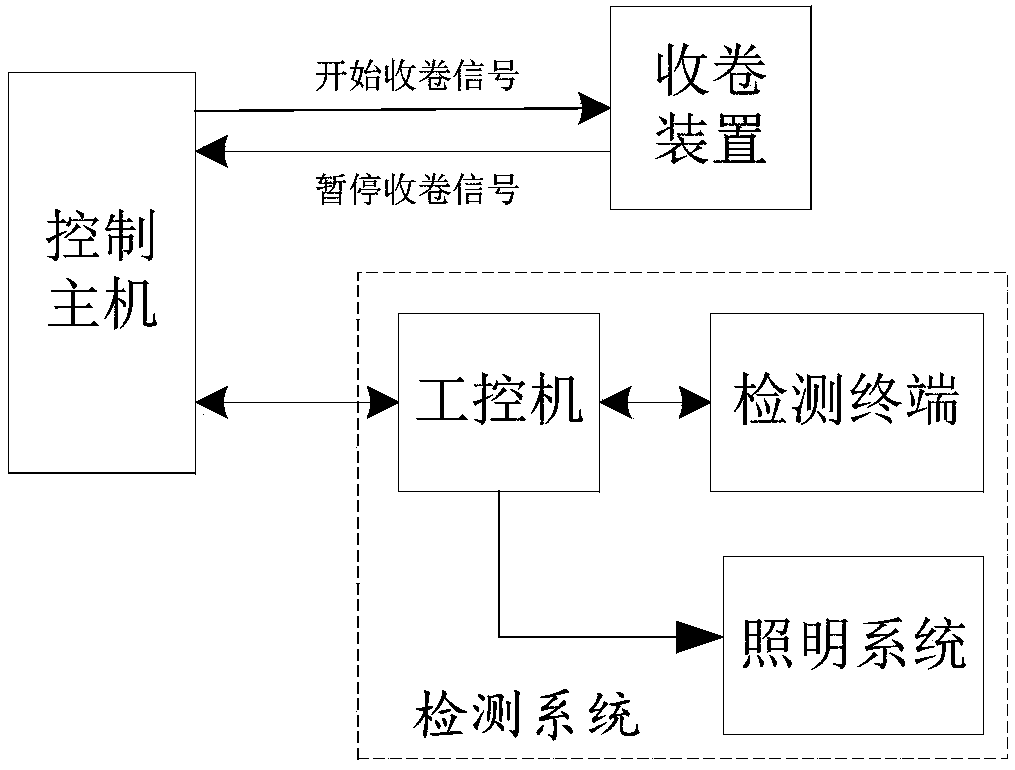

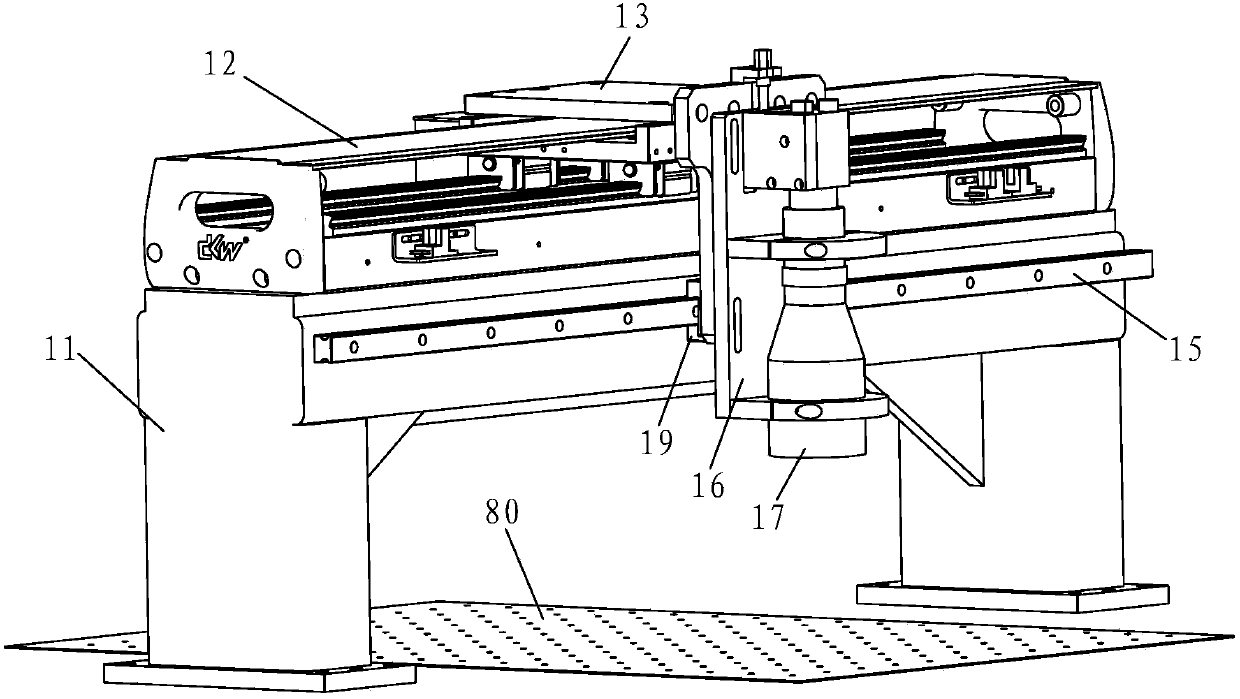

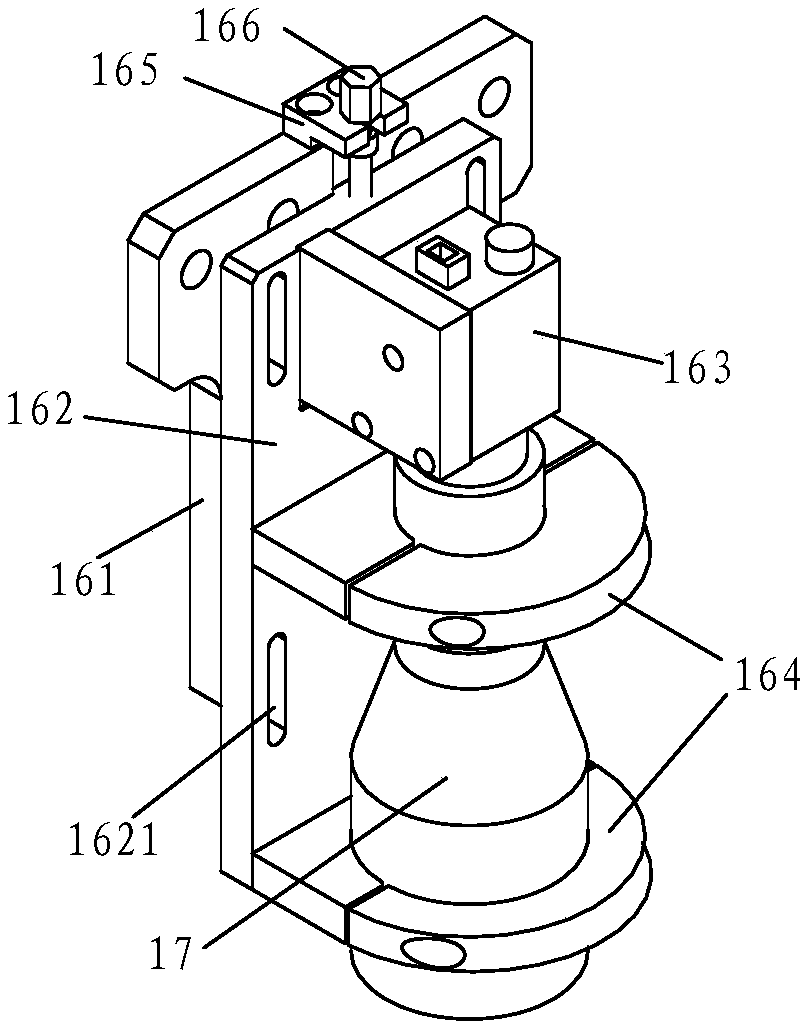

[0042] combine figure 1 As shown, the present invention proposes a steel strip punching processing detection system based on visual measurement, which mainly includes an industrial computer, at least one detection terminal and a lighting system located below the punched steel strip. The detection terminal and the lighting system are all connected to the industrial computer Connected, the lighting system provides a light source with stable brightness and no flickering so that the detection terminal can collect the upper surface image of the punched steel strip (also known as "steel strip surface image" or "steel strip upper surface image" or "steel strip image" even "surface images").

[0043] The existing punching processing production line already has a steel strip processing control system, which includes a control host and a winding device. The industrial computer is connected with the control host through the RS232 interface, and communicates with the control host using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com