Low-frosting blue light red nylon material and preparation method thereof

A technology of nylon and blue light, which is applied in the field of nylon material processing, can solve problems such as easy blooming, and achieve the effects of preventing blooming, simple operation and stable color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-2

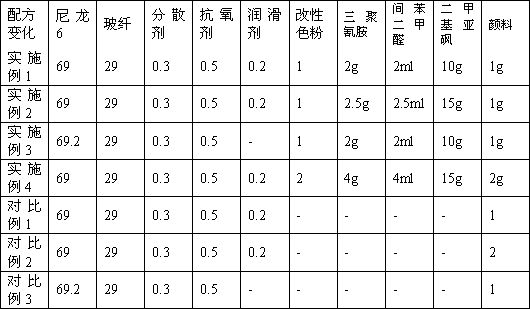

[0041] The formulations of Examples 1-4 and Comparative Examples 1-2 are shown in Table 1, and the units are parts by weight. Examples 1 to 4 are modified toners, antioxidants, dispersants, PA6, etc., mixed uniformly according to the proportion, then melt blended, extruded at 250 ° C, drawn, cooled with water, air-dried and pelletized to obtain modified Granules, injection molded into swatches at 250°C. Comparative examples 1 and 2 are prepared by mixing unmodified toner, antioxidant, dispersant, PA6, etc. according to the ratio, and then melt blending, extruding at 250°C, drawing, cooling in water, and air-drying to pelletize. Modified pellets, injection molded into color plates at 250°C.

[0042] The preparation method of the modified toner in Examples 1 to 4 includes: at room temperature, add melamine, m-phthalaldehyde and solvent to the reactor, stir to dissolve the solid powder completely, then add the pigment and continue to stir for 3-5min, and the reactor is heated C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com