Preparation method of white light OLED new material

A new material, white light technology, applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of chromophore color instability, poor device performance, phase separation, etc. The effect of improved performance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

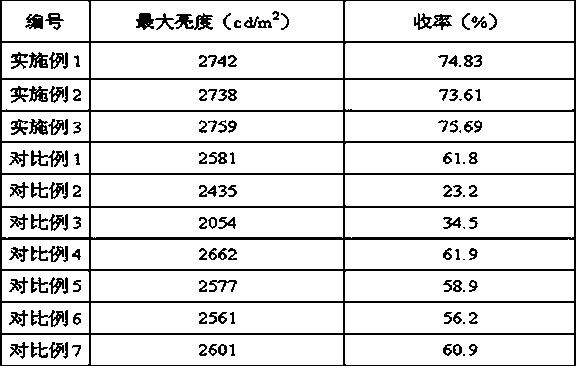

Examples

Embodiment 1

[0020] A preparation method of a new white light OLED material, the preparation technical scheme is as follows:

[0021] Step 1, the synthesis of intermediates: according to the mass parts, 2.7 parts of 2,7-dibromofluorenone, 2.3 parts of 2-thiophene boronic acid and 50 parts of dimethylformamide were added to the glass reactor, and then At room temperature, stir for 25 minutes until completely dissolved, then add 2.1 parts of sodium carbonate, 0.08 parts of catalyst tetrakis(triphenylphosphine) nickel and 45 parts of dimethylformamide, continue stirring for 60 minutes; then raise the temperature to 100°C , reacted for 13h; completed the reaction, added 400 parts of the system into ice water for precipitation, filtered and washed three times with methanol and ether, and dried in vacuum at 70°C for 8 hours to obtain a red solid; 3.6 parts of the red solid and 0.3 parts of Benzoyl peroxide is dissolved in 100 parts of dimethylformamide, the temperature of the control system is 8...

Embodiment 2

[0029] Step 1. Synthesis of intermediates: According to the parts by mass, 2.4 parts of 2,7-dibromofluorenone, 2.0 parts of 2-thiophene boronic acid and 40 parts of dimethylformamide were added to the glass reactor, Then at room temperature, stir for 20min to completely dissolve, then add 1.8 parts of sodium carbonate, 0.05 parts of catalyst tetrakis (triphenylphosphine) nickel and 40 parts of dimethylformamide, continue to stir for 50min; then heat up to 90 ℃, reacted for 10 h; after the reaction was completed, the system was added to 380 parts of ice water for precipitation, filtered, washed three times with methanol and ether, and dried in vacuum at 60 °C for 5 h to obtain a red solid; 3.2 parts of the red solid and 0.1 parts of The benzoyl peroxide is dissolved in 80 parts of dimethylformamide, the temperature of the control system is 5°C, and then 30 parts of dimethylformamide solution of 3.6 parts of N-bromosuccinimide are dissolved , slowly added dropwise to the system,...

Embodiment 3

[0037] Step 1, the synthesis of intermediates: according to the mass parts, 3.0 parts of 2,7-dibromofluorenone, 2.5 parts of 2-thiophene boronic acid and 60 parts of dimethylformamide were added to the glass reactor, and then At room temperature, stir for 30 minutes until completely dissolved, then add 2.4 parts of sodium carbonate, 0.10 parts of catalyst tetrakis(triphenylphosphine) nickel and 50 parts of dimethylformamide, continue stirring for 70 minutes; then heat up to 110°C , reacted for 15h; completed the reaction, added 420 parts of the system to ice water for precipitation, filtered and washed three times with methanol and ether, and dried in vacuum at 80°C for 10 hours to obtain a red solid; 3.8 parts of the red solid and 0.5 parts of Benzoyl peroxide is dissolved in 120 parts of dimethylformamide, and the temperature of the control system is 10°C, and then 40 parts of dimethylformamide solution of 4.2 parts of N-bromosuccinimide are dissolved, Slowly add dropwise to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com