Full-automatic omnibearing rubber roller cleaning device

A cleaning device and all-round technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve problems such as uneven surface of rubber rollers, affecting product quality, surface vitrification, etc., to achieve color stability, labor saving, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

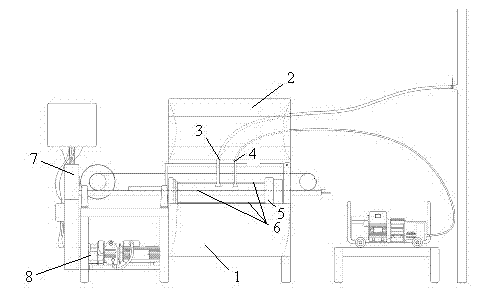

[0021] Rubber roller cleaning device of the present invention such as figure 1 shown. The cleaning operation procedure is as follows.

[0022] Fix the rubber roller on the cylindrical support 5, and lock the locking compass (lock wheel) to prevent the rubber roller from falling off. Close the workbench upper cover 2, open the tap water valve, and then turn on the power supply of the booster pump to pressurize the tap water. Start the left and right swing motor 7 of the high-pressure water nozzle, and the high-pressure water nozzle 3 swings left and right in the horizontal direction, and starts to clean the rubber roller. Start rubber roller to rotate motor 8, and rubber roller does circular rotation. Turn off the tap water valve after cleaning twice. Open the 4 valves of the drying hole, use compressed air to dry the moisture inside the rubber roller, loosen the locking compass, and take off the rubber roller.

[0023] This specific embodiment is only to make readers more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com