Multi-color metal oxide electrochromic battery and preparation method and application thereof

An electrochromic and colored metal technology, applied in the field of optical technology and optoelectronic applications, can solve the problems of capacity decline, low coulombic efficiency, poor cycle performance, etc., and achieve the effect of small radiation influence, high capacity and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] In some embodiments, the preparation method includes: connecting the prepared multi-color manganese oxide electrochromic electrode with the metal zinc electrode with a zinc sulfate electrolyte to form a multi-color manganese oxide electrochromic battery.

[0089] In some embodiments, the preparation method of the multi-color metal oxide electrochromic electrode comprises:

[0090] By physical or chemical deposition methods, such as coating, printing, casting, etc., or magnetron sputtering, electron beam evaporation, thermal evaporation, electrochemical deposition, chemical vapor deposition, atomic force deposition, sol-gel technology, etc. to form the first An optical structure layer or a second optical structure layer, a medium layer, etc., and not limited thereto.

[0091] Further, the preparation method specifically includes:

[0092] provide a base;

[0093] By means of PVD deposition, the metal layer is first sputtered on the substrate, and then metal oxide diele...

Embodiment 1

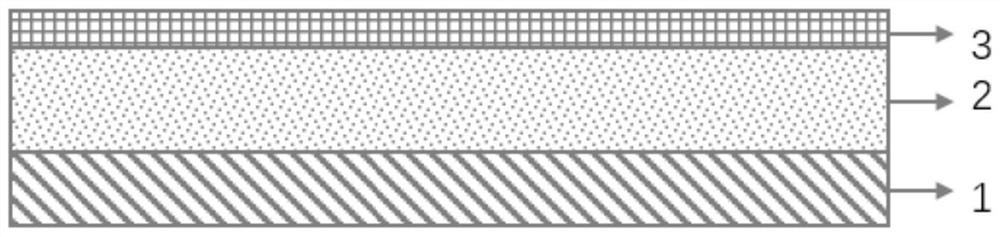

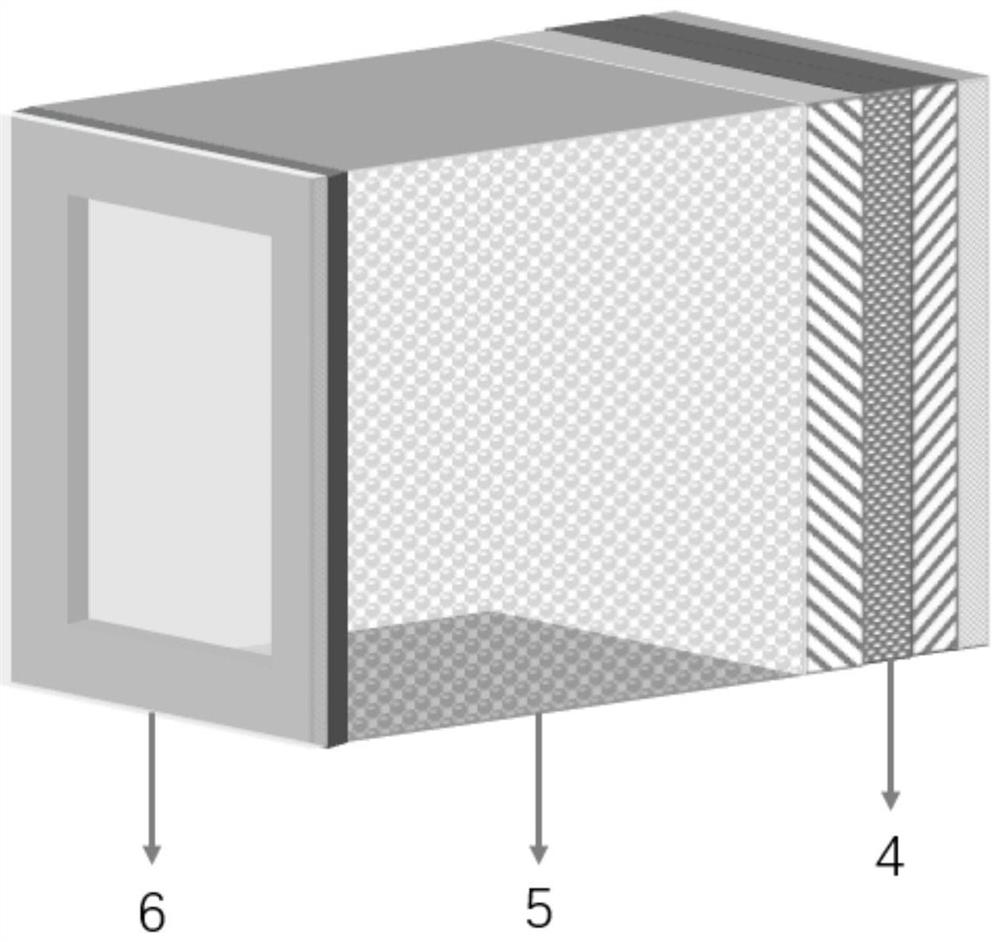

[0109] A multi-color manganese oxide electrochromic battery disclosed in this embodiment includes a multi-color manganese oxide electrochromic electrode 4, a metal zinc electrode 6 and an electrolyte 5, which can be referred to figure 2 shown. Among them, the multi-color manganese oxide electrochromic electrode is composed of substrate 1, metal reflective layer 2, and dielectric layer manganese oxide 3, which can be referred to figure 1 shown.

[0110] The preparation method of the multi-color manganese oxide electrochromic battery of this embodiment is as follows: on a clean base glass, a metal Cu film is deposited by magnetron sputtering, wherein the thickness of the Cu film is set at 100 nm. Afterwards, a layer of MnO was sputtered on the surface of the film by magnetron sputtering. 2 film, where MnO 2 The film thickness was set at 180 nm. The multi-color manganese oxide electrochromic electrode and the metal zinc sheet are obtained to form a battery, and the electroly...

Embodiment 2

[0113] A multi-color manganese oxide electrochromic battery disclosed in this embodiment includes a multi-color manganese oxide electrochromic electrode 4, a metal zinc electrode 6 and an electrolyte 5, which can be referred to figure 2 shown. Among them, the multi-color manganese oxide electrochromic electrode is composed of substrate 1, metal reflective layer 2, and dielectric layer manganese oxide 3, which can be referred to figure 1 shown.

[0114]The preparation method of the multi-color manganese oxide electrochromic battery of this embodiment is as follows: on a clean substrate glass, a layer of metal W film is firstly deposited by magnetron sputtering, wherein the thickness of the W film is set at 100 nm. Afterwards, a layer of MnO was sputtered on the surface of the film by magnetron sputtering. 2 film, where MnO 2 The film thickness was set at 180 nm. The multi-color manganese oxide electrochromic electrode and the metal zinc sheet are obtained to form a battery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com