Device for automatically spraying glaze to open ceramic product

A technology for ceramic products and glaze spraying is applied in the field of automatic glaze spraying devices for open ceramic products, which can solve the problems of uneven thickness of glaze, uneven glaze layer, slow production speed, etc. The effect of improving the quality of spray glaze and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

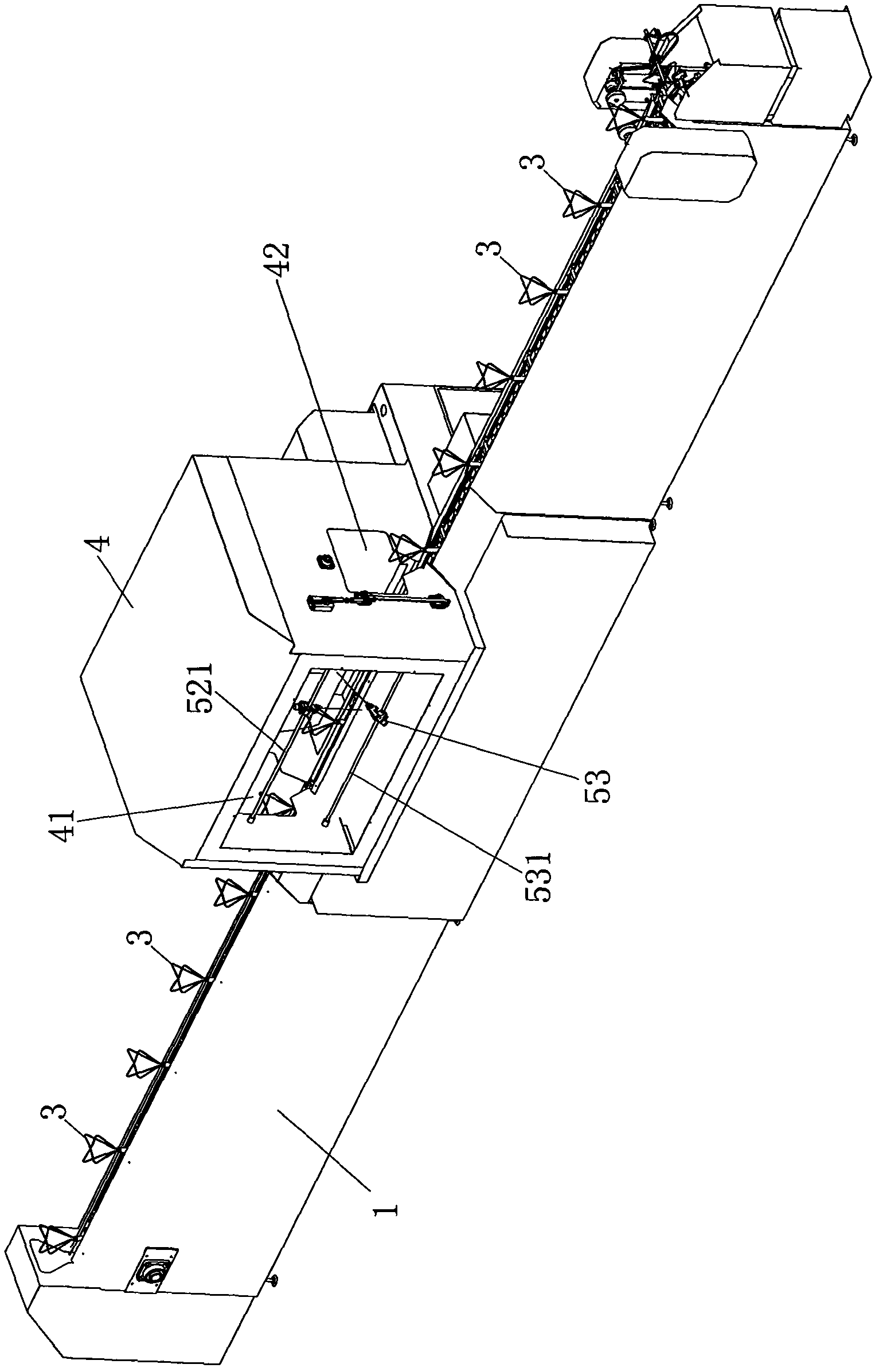

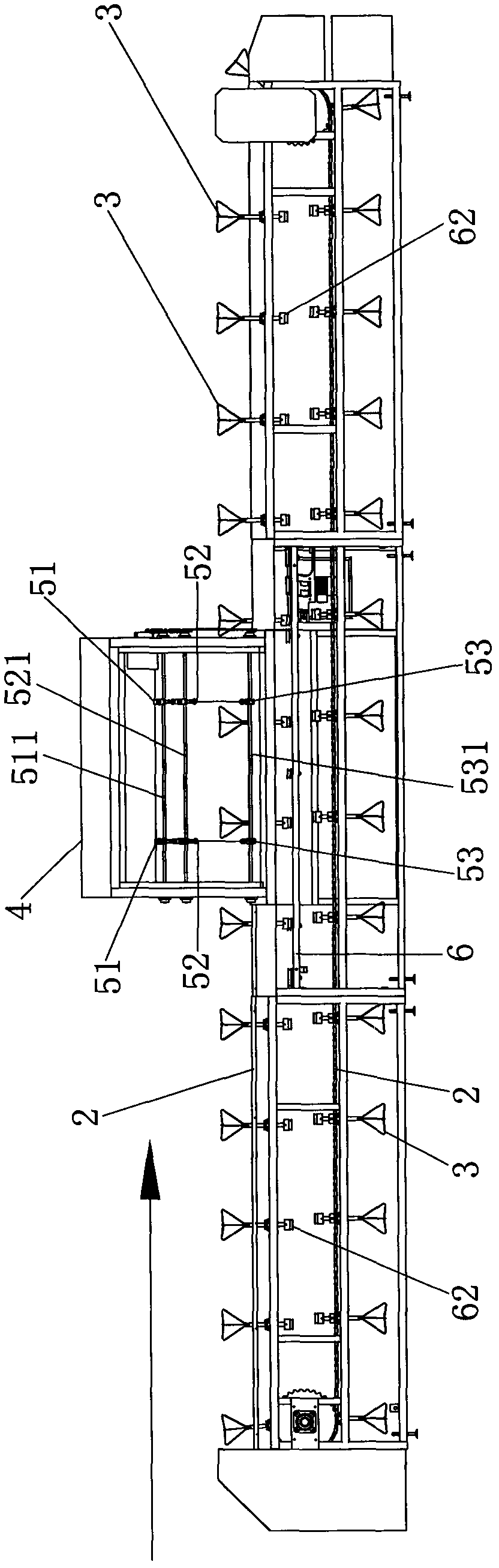

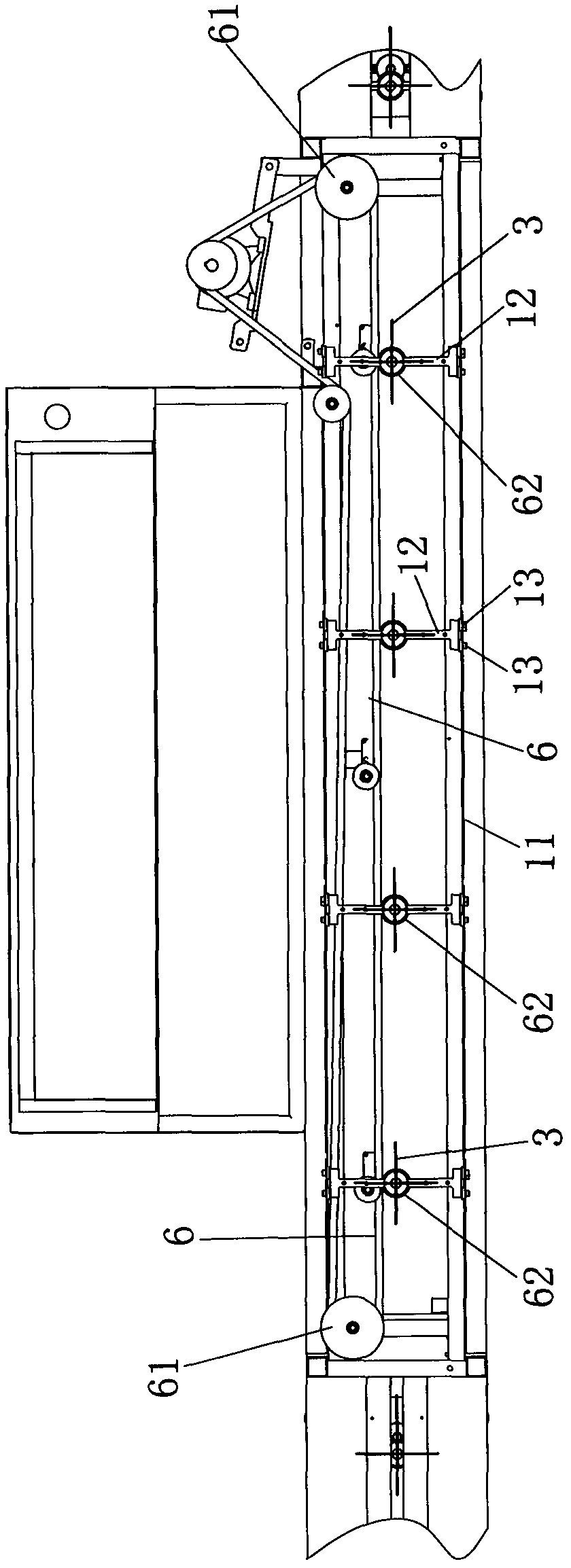

[0025] figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 As shown, the automatic glaze spraying device for open ceramic products includes a frame 1, the frame is provided with a first motor 21, and two circulating chains 2 arranged side by side on the left and right, the structure and length of the two circulating chains are the same, and the two circulating chains 2 The sprocket wheel 22 is synchronously driven by the first motor 21; a longitudinal guide rail 11 is respectively installed next to the upper horizontal section of each endless chain. Twenty-eight horizontal bars 12 are connected between the left and right circulating chains, and each horizontal bar is evenly arranged along the circumferential direction of the circulating chain. Each horizontal bar 2 center is rotatably equipped with a workpiece support 3 for placing ceramic products. The left and right sides of each horizontal bar 12 are respectively fixedly connected with one of the chain links of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com