Glazing method of jun porcelain glaze

A technology of Jun porcelain and glaze, applied in the field of glazing of Jun porcelain glaze, can solve the problems of large workload, affecting the quality of Jun porcelain products, and inability to guarantee the accuracy of the glazing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

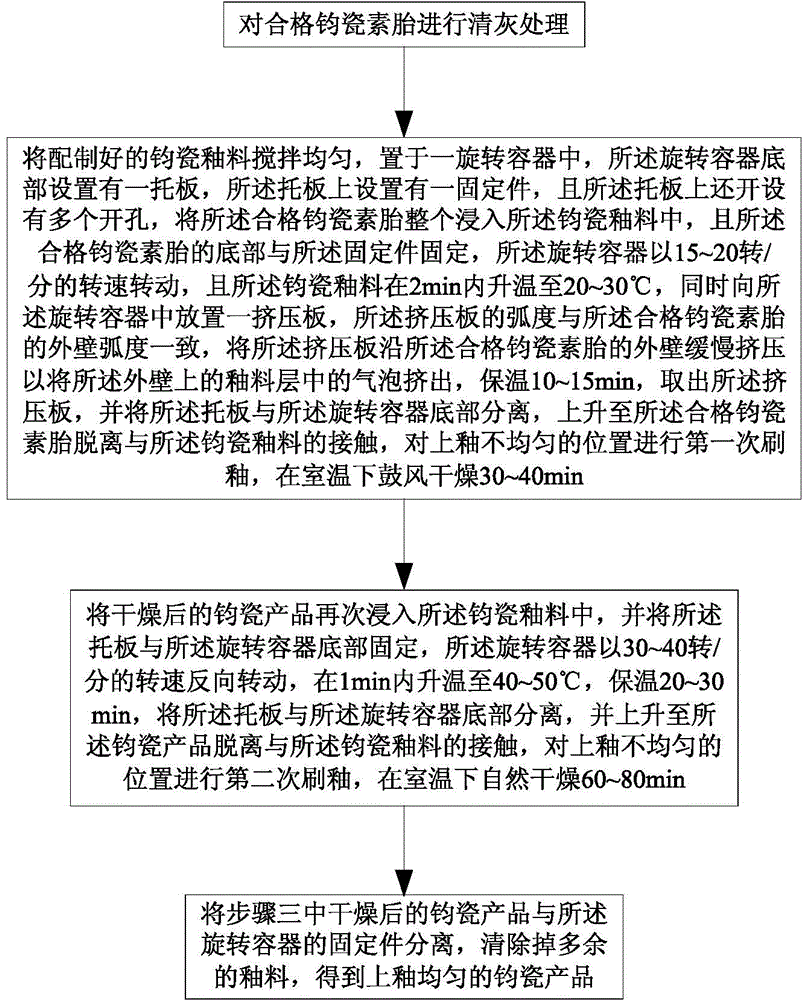

[0020] Such as figure 1 Shown, the present invention provides a kind of glazing method of Jun porcelain glaze, comprises the following steps:

[0021] Step 1: Clean the dust of the qualified Jun porcelain plain body. Brush the ash residue on the inner surface and outer surface of the qualified Jun porcelain plain body with a brush to prevent slag particles from appearing on the glaze surface and affect the quality of the glaze surface, and spray a small amount of clear water on the inner surface and outer surface of the qualified Jun porcelain plain body to make it dry. It is soaked to make the glaze layer and the surface of Jun porcelain firmly bonded after glazing.

[0022] Step 2: Stir the prepared Jun porcelain glaze evenly, and place it in a rotating container, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com