Ceramic product, and preparing and sintering process thereof

A technology of ceramic products and porcelain stones, which is applied in the field of ceramic products and their preparation and firing process, to achieve the effects of reducing production costs, improving the appearance and exquisiteness, and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

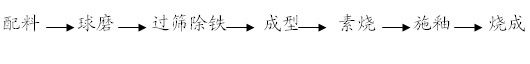

[0033] The raw material components of ceramic products include washed kaolin, Changxing white clay, Fujian porcelain stone, feldspar, and burnt talc. The preparation and firing steps are as follows ( figure 1 ):

[0034] (1) Prepare ceramic products according to the following raw material weight percentages:

[0035] Washed Kaolin 54%;

[0036] Changxing white clay 18%;

[0037] Fujian porcelain stone 12%;

[0038] Feldspar 14%;

[0039] Burnt talc 2%.

[0040] (2) Put the above ingredients into the ball mill according to the weight ratio of ball: water = 1:1.1:0.6, add 0.15% of sodium humate and 0.3% of sodium humate into the cylinder ball mill, and after 24 hours of ball milling, the cylinder is discharged Pass through a 120-mesh sieve to remove iron, and make grouting blanks for ceramic products.

[0041] (3) The above-mentioned grouting blanks are made by grouting molding. The blanks are bisque-fired at 1030°C, and beige glaze is applied by dipping glaze. After dryin...

Embodiment 2

[0043] The raw material components of ceramic products include washed kaolin, Changxing white clay, Fujian porcelain stone, feldspar, and burnt talc. The preparation and firing steps are as follows ( figure 1 ):

[0044] (1) Prepare ceramic products according to the following raw material weight percentages:

[0045] Washed Kaolin 50%;

[0046] Changxing white clay 24%;

[0047] Fujian porcelain stone 14%;

[0048] Feldspar 11%;

[0049] Burnt talc 1%.

[0050] (2) Put the above ingredients into the ball mill according to the weight ratio of ball: water = 1:1.1:0.6, add 0.2% sodium humate and 0.35% sodium humate by weight of the ingredients into the ball mill, after 24 hours of ball milling, out of the barrel Pass through a 100-mesh sieve to remove iron, and make a grouting blank for ceramic products.

[0051] (3) The above-mentioned grouting blanks are made by grouting molding. The blanks are bisque-fired at 1025°C, and coffee glaze is applied by dipping glaze. After dr...

Embodiment 3

[0053] The raw material components of ceramic products include washed kaolin, Changxing white clay, Fujian porcelain stone, feldspar, and burnt talc. The preparation and firing steps are as follows ( figure 1 ):

[0054] (1) Prepare ceramic products according to the following raw material weight percentages:

[0055] Washed Kaolin 51%;

[0056] Changxing white clay 17%;

[0057] Fujian porcelain stone 11%;

[0058] Feldspar 19%;

[0059] Burnt talc 2%.

[0060] (2) Put the above ingredients into the ball mill according to the weight ratio of ball: water = 1:1.1:0.6, add 0.15% of sodium humate and 0.35% of sodium humate into the ball mill, and after 24 hours of ball milling, it will be out of the barrel Pass through a 140-mesh sieve to remove iron, and make a grouting blank for ceramic products.

[0061] (3) The above-mentioned grouting blanks are made by grouting molding. The blanks are bisque fired at 1035°C, and the deep blue glaze is applied by dipping glaze. After dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com