Surface galvanizing technology for guide hook of drop-out fuse

A drop-out fuse and process technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem of no improvement in wear resistance, poor ability to adapt to the environment, and uneven galvanized layer, etc. problems, to achieve the effect of improving the appearance of the coating, preventing excessive corrosion, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

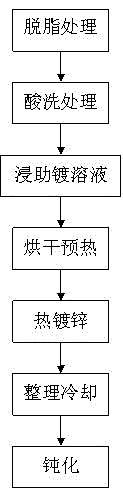

[0021] see figure 1 , the embodiment of the present invention includes:

[0022] A surface galvanizing process for a guide hook of a drop-out fuse, wherein the material of the guide hook of the drop-out fuse is iron, comprising the following steps:

[0023] 1) Degreasing treatment: completely soak the guide hook in the degreasing cleaning agent to remove the surface oil, and then wash it with running water;

[0024] 2) Pickling treatment: Etch the degreased guide hook in sulfuric acid aqueous solution to remove the oxide film on the surface of the guide hook, then wash with water and dry, wherein the sulfuric acid aqueous solution contains 0.1%-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com