Diamond/block copper substrate diffusion bonding process and structure based on diamond indirect stretching structure

A tensile structure and diffusion bonding technology, used in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problem that the stretching of diamond films cannot be achieved in batches, the flatness of the bonding interface is uneven, and the effect of affecting diffusion bonding, etc. problems, to avoid organic particles sticking, the bonding pressure is concentrated, and the solder layer is too thick.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

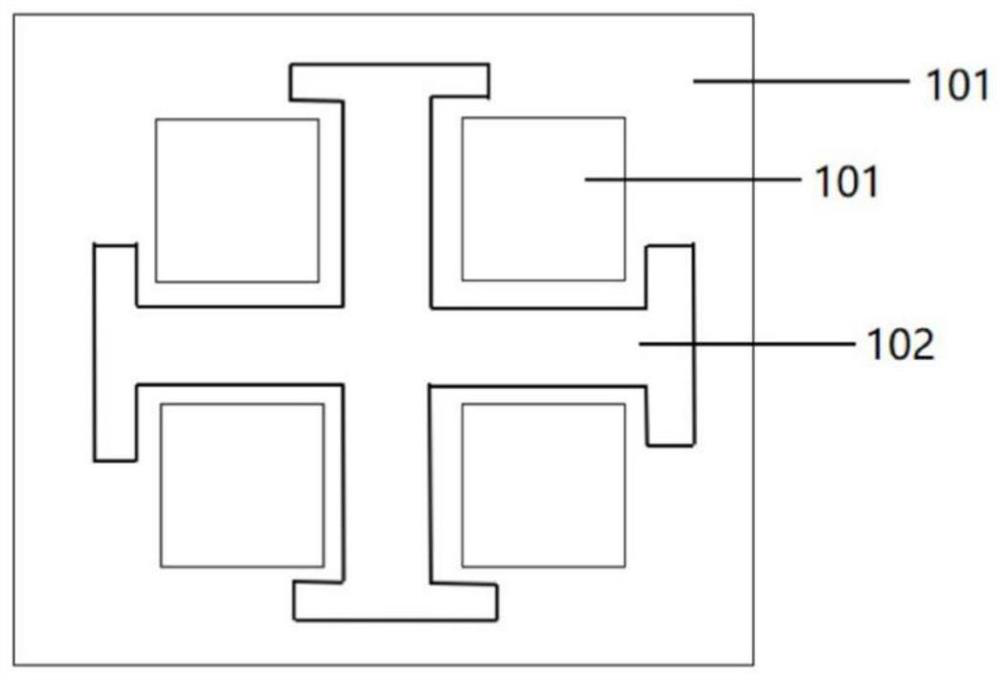

[0054] In this embodiment, a diamond / block copper substrate diffusion bonding process based on the diamond indirect tensile structure comprises the following steps:

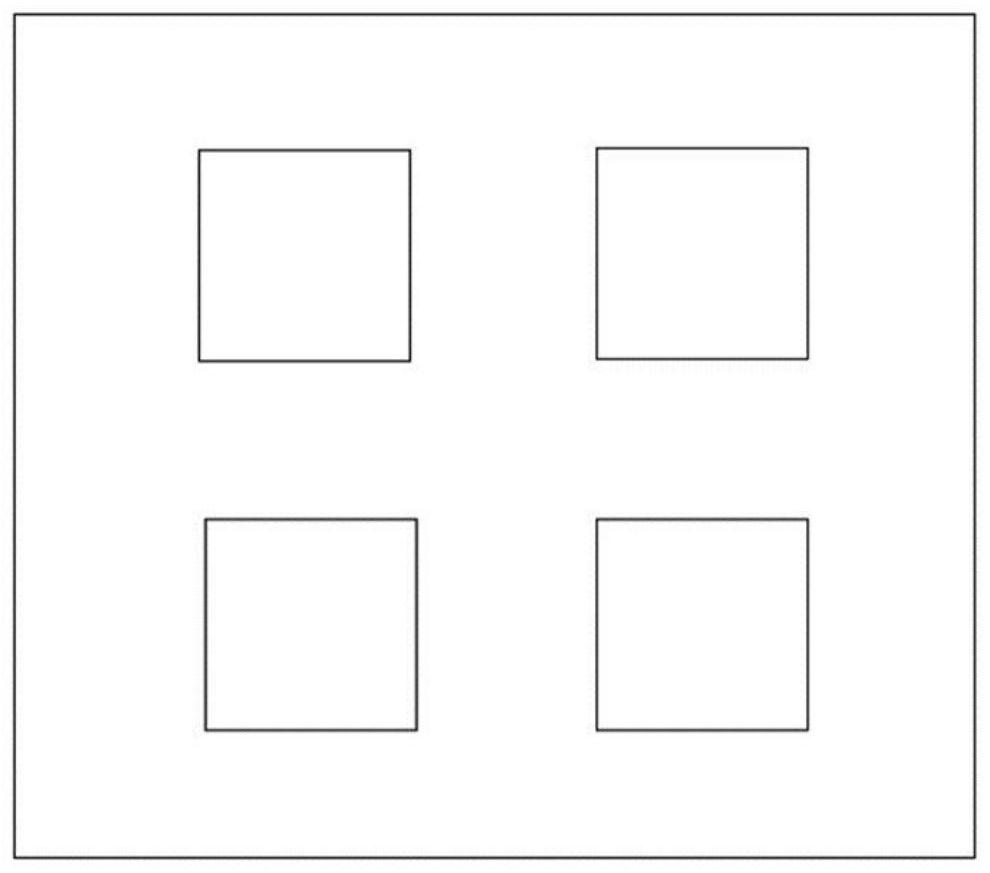

[0055] 1) A wet etching method is used to obtain three-dimensional geometric figures arranged in an array on the surface of the bulk copper substrate.

[0056] 2) Perform mechanical polishing on the surface of the bulk copper substrate to make the surface flatness lower than 800nm (not limited to this), and the roughness to be 100-500nm (not limited to this), and use plasma cleaning to remove surface impurities.

[0057] 3) Nano-silver solder is selected, and nano-silver is sputtered onto the bulk copper substrate to ensure that the thickness of the solder layer is uniform. At the same time, high-temperature treatment can make part of the solder layer fall off to control the thickness of the solder layer.

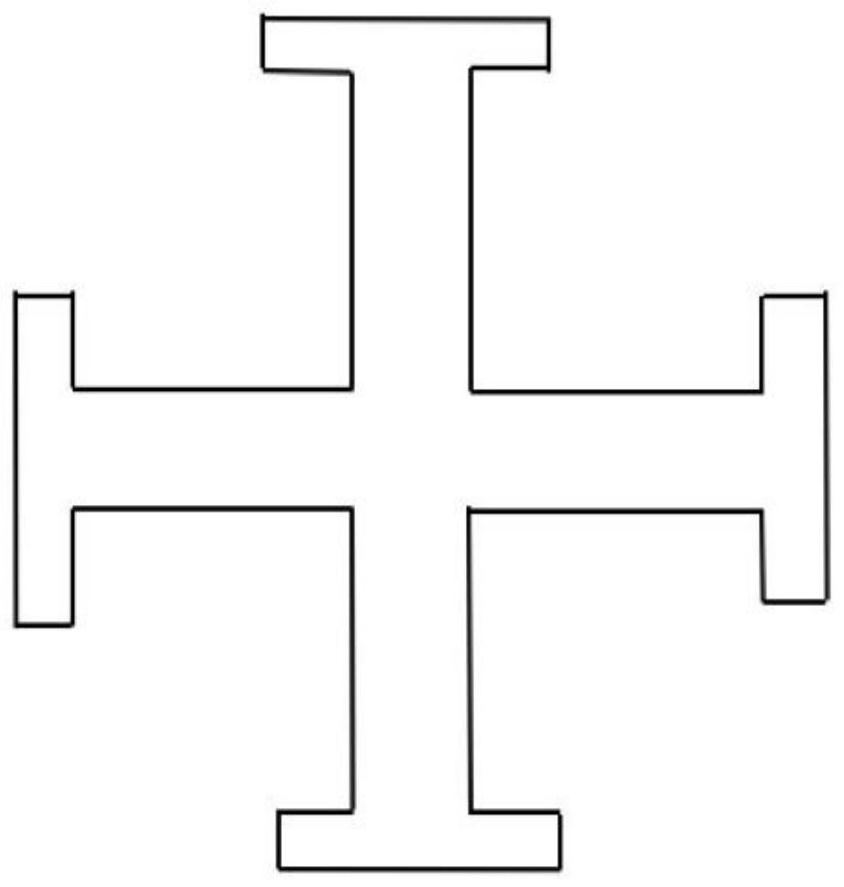

[0058] 4) In a vacuum environment, make the diamond film into a "cross" structure and embed it, apply a pre...

Embodiment 2

[0061] Such as Image 6 As shown, another embodiment of the diamond / block copper substrate diffusion bonding process and structure based on the diamond indirect tensile structure, its difference from Example 1 is that the wet etching method is used on the block copper substrate A groove in the shape of the diamond film is obtained, so that the diamond film is embedded in it, and the indirect stretching of the diamond film can also be realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com