Saving-type environment-friendly electroplating spraying box

An energy-saving and environment-friendly technology, applied in coating, spray booth, spraying device, etc., can solve problems such as shedding, falling, and wrinkling of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] as attached figure 1 to attach Figure 6 Shown:

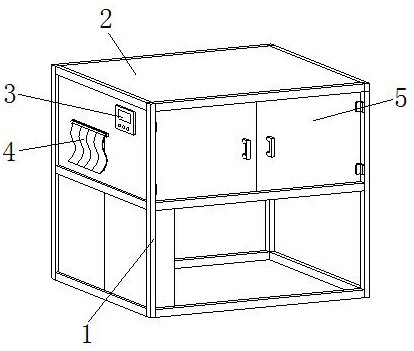

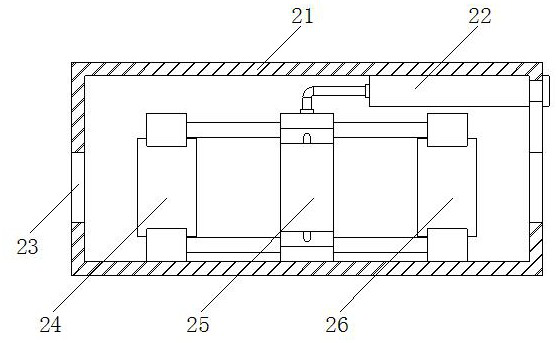

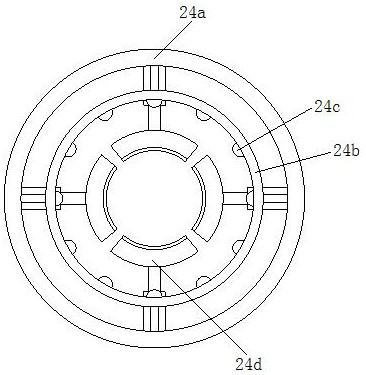

[0025] The present invention is an energy-saving and environment-friendly electroplating spraying box, its structure includes a support frame 1, a spraying box 2, a control panel 3, a shielding cloth 4, and a box door 5, the upper end of the support frame 1 is welded to the outside of the spraying box 2, and the A control panel 3 is embedded on the outer surface of the spraying box 2, the cover cloth 4 is installed on the left side surface of the spraying box 2, the door 5 is hingedly connected with the front end of the spraying box 2, and the spraying box 2 includes a box body 21, a paint box 22. The pipe inlet 23, the water removal mechanism 24, the spraying mechanism 25, and the smoothing mechanism 26. The paint box 22 is fixedly installed at the upper right end inside the box body 21, and the pipe inlet 23 is embedded in the left side of the box body 21. And the outer side of the pipe inlet 23 is provided with a sh...

Embodiment 2

[0033] as attached Figure 7 to attach Figure 8 Shown:

[0034] Wherein, the smoothing mechanism 26 includes a support ring 261, a fixed sleeve 262, a spring 263, and a support bracket 264. The support ring 261 is fixedly installed at the right end inside the box body 21, and the inner bottom of the support ring 261 is provided with a fixed Pipe sleeve 262, and fixed pipe sleeve 262 inside is provided with spring 263, and the bottom of described supporting bracket 264 is fixed with the top of spring 263, and described supporting ring 261 is circular structure, and the center of circle of supporting ring 261 and rotating ring tube The center of circle of f3 is located on the same horizontal line, which is beneficial to the positioning of the circle center of the round tube and ensures the smooth transmission of the round tube.

[0035] Wherein, the support bracket 264 includes a bracket 64a, a scraper 64b, a groove 64c, the bottom of the bracket 64a is fixed to the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com