Preparation method of instant tough and chewy coarse cereal nutritious noodles

A technology for miscellaneous grains and noodles, applied in food science, vegetable protein processing and other directions, can solve the problems of noodles losing their gluten taste, easy melting of glue additives, unable to meet the pace of life, etc. The effect of noodles being too thick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

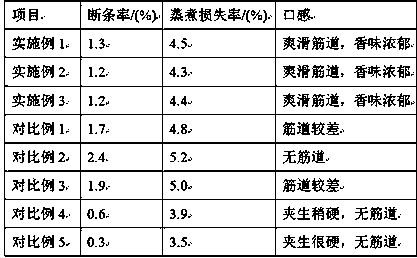

Examples

Embodiment 1

[0026] A preparation method for instant gluten multigrain nutritional noodles, comprising the following steps:

[0027] (1) Miscellaneous grain dough: Weigh the miscellaneous grain powder by weight, and the miscellaneous grain powder is composed of the following raw materials by weight: buckwheat flour 47, oat flour 34, corn flour 10; add miscellaneous grain flour 32% by weight Boiling water, stir quickly and evenly, so that the miscellaneous grain powder can be quickly matured at high temperature, increase the fragrance and cohesiveness of the miscellaneous grain powder, and can quickly bond with the flour, which is conducive to noodle processing and shaping, and improves the texture and taste of the noodles to obtain miscellaneous grain dough.

[0028] (2) One-time kneading: add whole wheat flour to the miscellaneous grain dough, the weight is 1.3 times the weight of the miscellaneous grain powder, adjust to 26% water content, stir at 42r / min for 10min, until the surface of t...

Embodiment 2

[0038] A preparation method for instant gluten multigrain nutritional noodles, comprising the following steps:

[0039] (1) Miscellaneous grain dough: Weigh the miscellaneous grain powder by weight, and the miscellaneous grain powder is composed of the following raw materials by weight: buckwheat flour 48, oat flour 35, corn flour 11; add miscellaneous grain flour 33% by weight Boiling water, stir quickly and evenly, so that the miscellaneous grain powder can be quickly matured at high temperature, increase the fragrance and cohesiveness of the miscellaneous grain powder, and can quickly bond with the flour, which is conducive to noodle processing and shaping, and improves the texture and taste of the noodles to obtain miscellaneous grain dough.

[0040] (2) One-time kneading: add whole wheat flour to the miscellaneous grain dough, the weight is 1.4 times the weight of the miscellaneous grain powder, adjust to 27% water content, stir at 43r / min for 13min, until the surface of t...

Embodiment 3

[0050] A preparation method for instant gluten multigrain nutritional noodles, comprising the following steps:

[0051] (1) Miscellaneous grain dough: Weigh the miscellaneous grain powder by weight, and the miscellaneous grain powder is composed of the following raw materials by weight: buckwheat flour 49, oat flour 36, corn flour 12; add miscellaneous grain flour 34% by weight Boiling water, stir quickly and evenly, so that the miscellaneous grain powder can be quickly matured at high temperature, increase the fragrance and cohesiveness of the miscellaneous grain powder, and can quickly bond with the flour, which is conducive to noodle processing and shaping, and improves the texture and taste of the noodles to obtain miscellaneous grain dough.

[0052] (2) One-time kneading: add whole wheat flour to the miscellaneous grain dough, the weight is 1.5 times the weight of the miscellaneous grain powder, adjust to 28% water content, stir at 44r / min for 15min, until the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com