Preparation method of bituminous concrete

A technology of asphalt concrete and support seat, which is applied in the field of asphalt concrete, can solve the problems of affecting the ratio of asphalt and concrete, the inability to heat and emulsify asphalt, and affecting the quality of asphalt concrete, so as to improve the quality and increase the viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

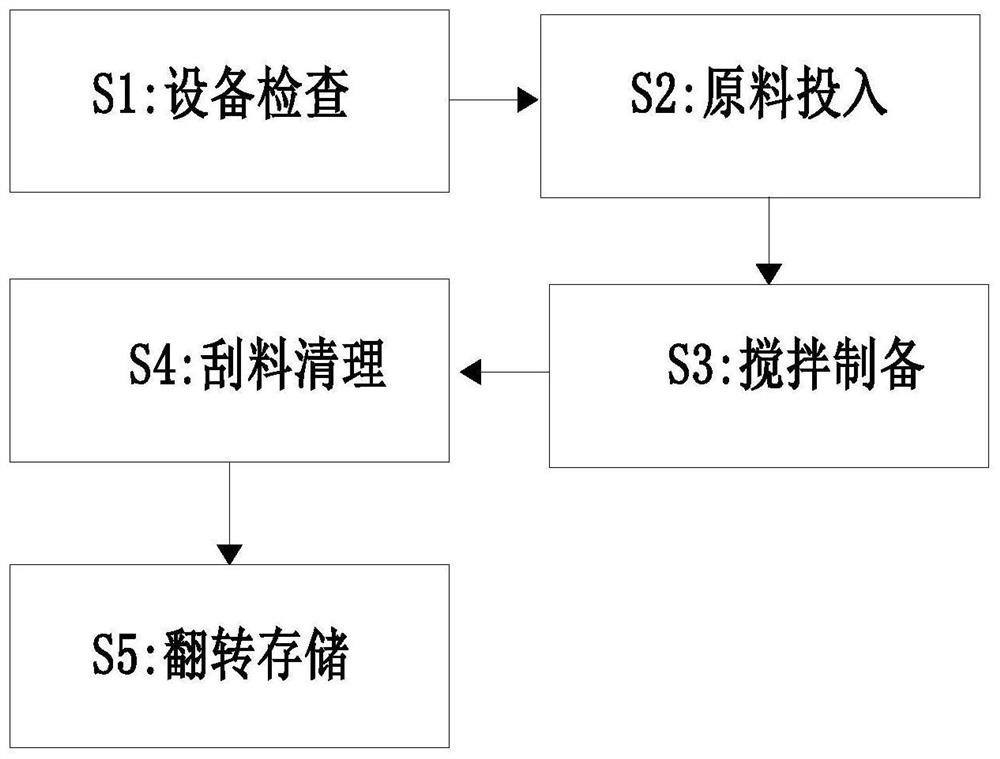

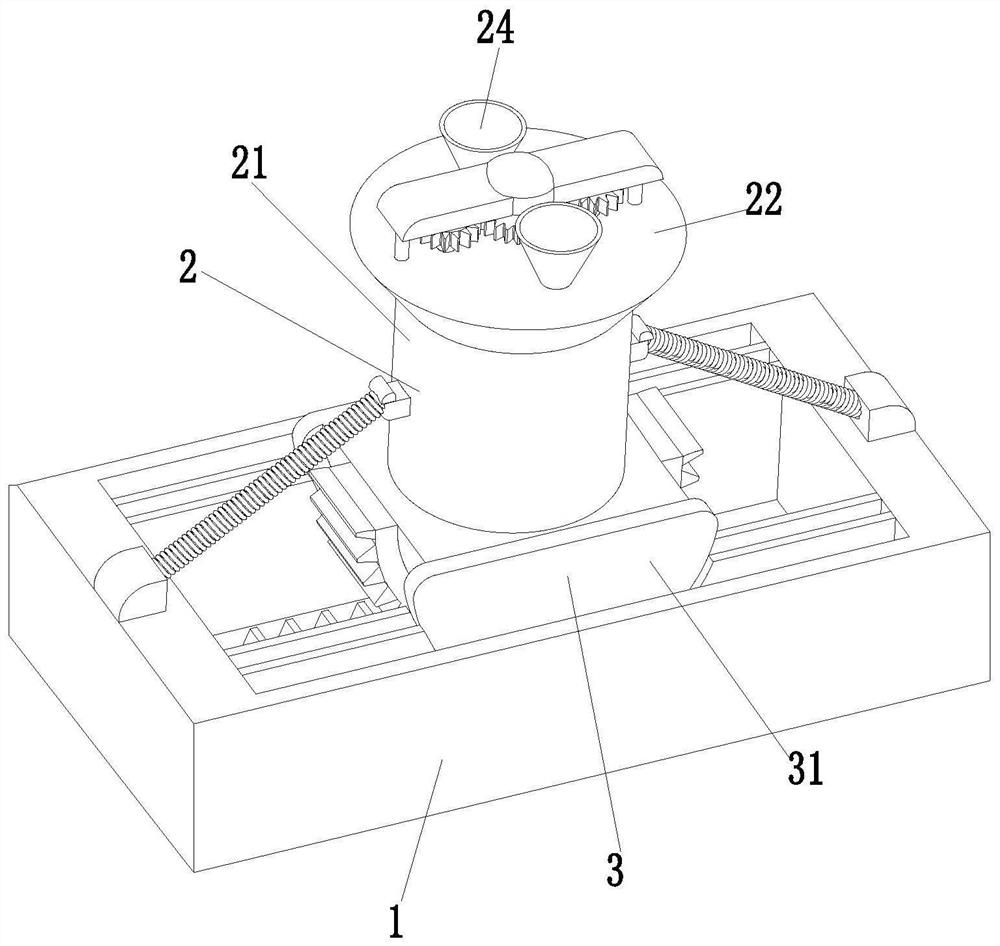

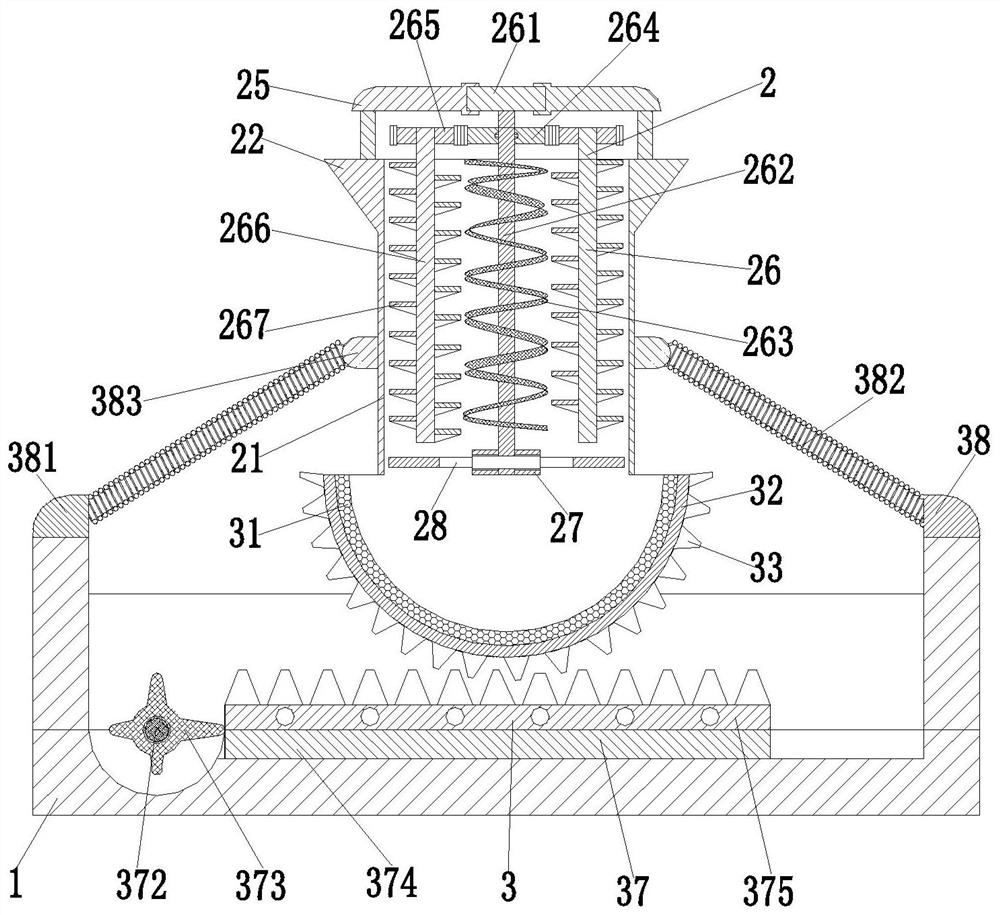

[0035] like Figure 1 to Figure 8 As shown, a method for preparing asphalt concrete uses a device for assisting in the preparation of asphalt concrete. The device for assisting in preparing asphalt concrete includes a support base 1, a stirring mechanism 2 and a turning mechanism 3. The support base 1 is an opening For an upward box structure, a stirring mechanism 2 is installed in the middle of the support base 1, and a turning mechanism 3 is installed at the lower end of the stirring mechanism 2.

[0036]The stirring mechanism 2 includes a stirring tank 21, a circular pedestal 22, a heating block 23, a feed port 24, a motor frame 25, a stirring branch chain 26, a cross plate 27, an opening and closing branch chain 28 and a scraping branch chain 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com