Method for preparing slag conglomeration agent for iron steel

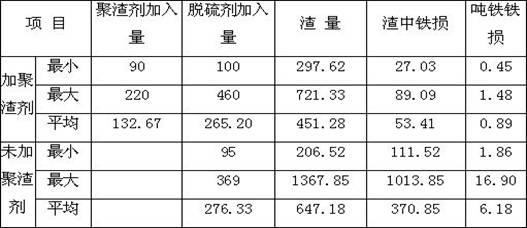

A slag-aggregating agent and iron and steel technology, which is applied in the field of preparation of iron and steel solution slag-aggregating agent, can solve the problems of affecting the consumption index of iron and steel materials, long slag removal time, loss of molten iron, etc. performance, the effect of reducing the iron loss of slag scavenging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] raw material:

[0021] Albite 18%; Fluorite 22%;

[0022] Waste glass 26%; Raw vermiculite 15%;

[0023] Calcium carbonate 15%; Salt 4%;

[0024] 1) Crushing albite, fluorite, vermiculite, calcium carbonate and waste glass;

[0025] 2) Grinding, the particle size of grinding is 1.6mm~2.5mm;

[0026] 3) Ingredients, mix the above materials;

[0027] 4) Mixing, adding salt and mixing, the mixing temperature is 25°C, and the mixing time is 20 minutes;

[0028] 5) Detecting and packaging to produce a slag accumulator with a capacity of more than 3 tons of molten iron.

Embodiment 2

[0030] raw material:

[0031] Albite 20%; Fluorite 21%;

[0032] Waste glass 28%; Raw vermiculite 12%;

[0033] Calcium carbonate 15%; Salt 4%;

[0034] 1) Crushing albite, fluorite, vermiculite, calcium carbonate and waste glass;

[0035] 2) Grinding, the particle size of grinding is 0.9mm~1.6mm;

[0036] 3) Ingredients, mix the above materials;

[0037] 4) Mixing, adding salt and mixing, the mixing temperature is 25°C, and the mixing time is 20 minutes;

[0038] 5) Detect and package to prepare a slag accumulator with a capacity of 2 to 3 tons of molten iron.

Embodiment 3

[0040] raw material:

[0041] Albite 15%; Fluorite 25%;

[0042] Waste glass 29%; Raw vermiculite 14%;

[0043] Calcium carbonate 14%; Salt 3%;

[0044] 1) Crushing albite, fluorite, vermiculite, calcium carbonate and waste glass;

[0045] 2) Grinding, the particle size of grinding is 0.45mm~0.9mm;

[0046] 3) Ingredients, mix the above materials;

[0047] 4) Mixing, adding salt and mixing, the mixing temperature is 25°C, and the mixing time is 20 minutes;

[0048] 5) Detecting and packaging to prepare a slag accumulator with a capacity of 1 to 2 tons of molten iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com