Wind distribution device facilitating discharging of big particle matter and multi-flow circulating fluidized bed boiler

A technology of circulating fluidized bed and air distribution device, which is applied in the directions of fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., to achieve the effect of being beneficial to slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

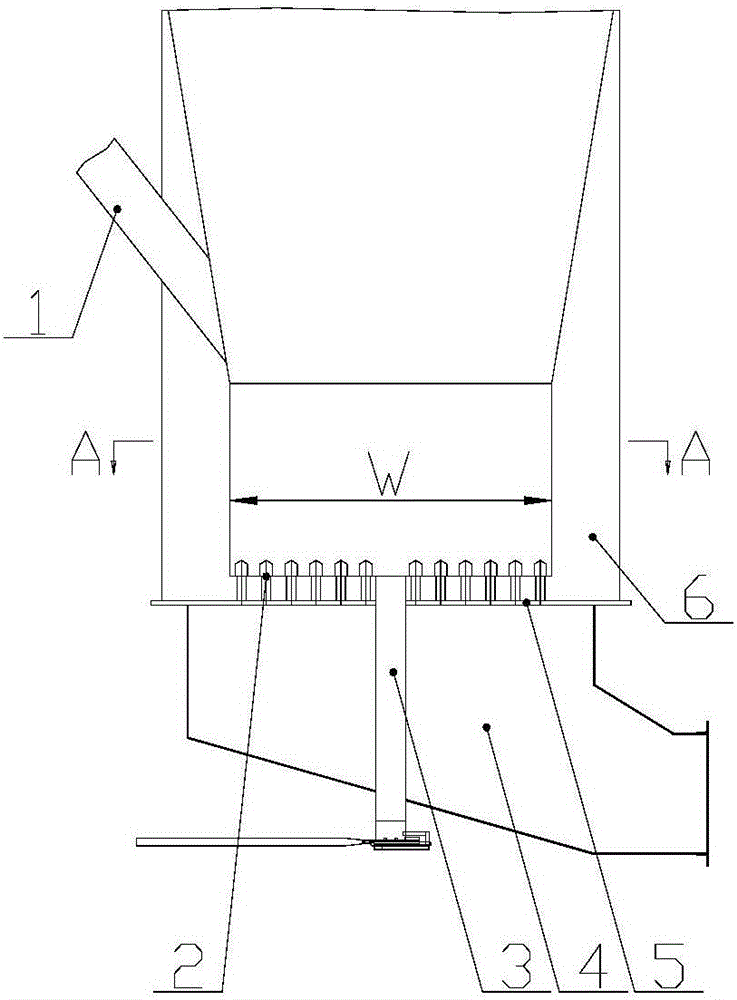

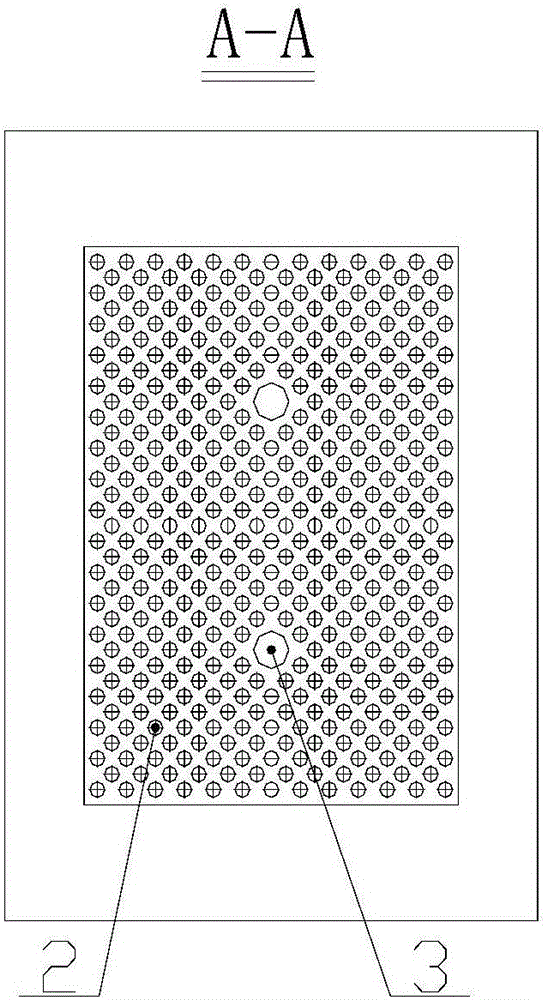

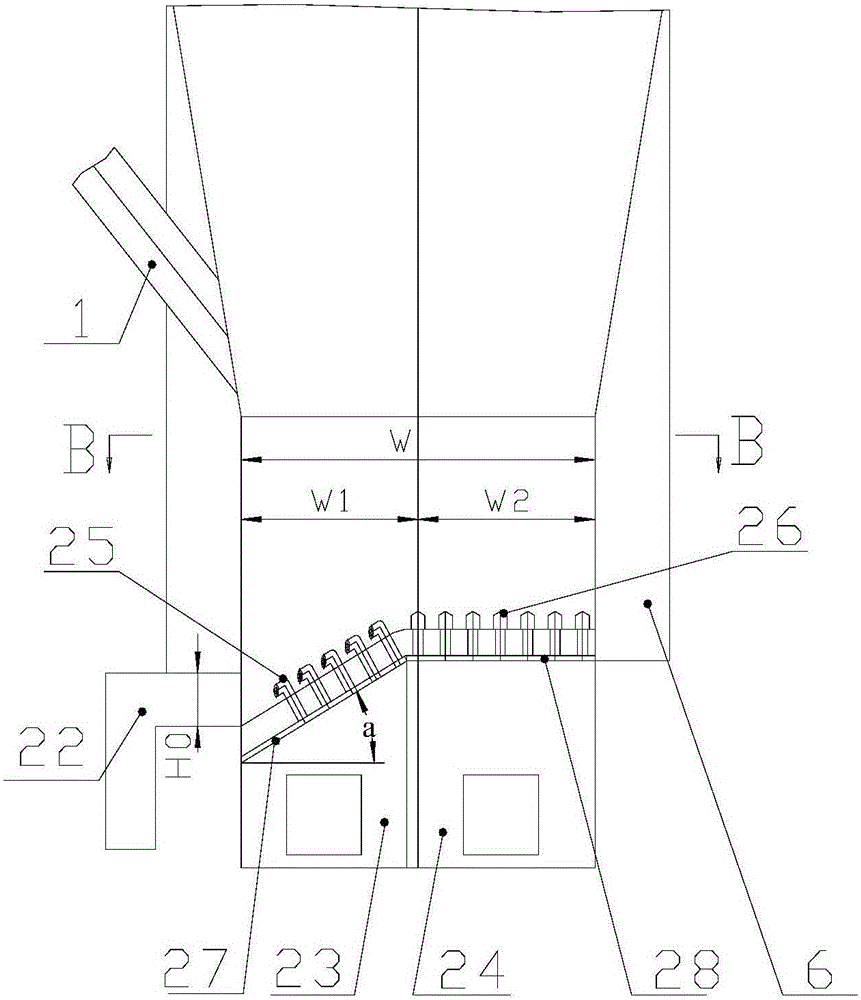

[0045] The invention provides an air distribution device which is beneficial to discharge large particles, and its structure is as follows Figure 3-Figure 4 Shown, including:

[0046] The slag pipe 22, the first air chamber 23, the second air chamber 24, the first air cap 25, the second air cap 26, the inclined air distribution plate 27, and the horizontal air distribution plate 28.

[0047] The horizontal air distribution plate 28 is arranged horizontally, and the inclined air distribution plate 27 is inclined downward from one end edge of the horizontal air distribution plate 28 and is set in the middle of the furnace of the circulating fluidized bed boiler after being butted with the horizontal air distribution plate 28; 28 and the remaining edges of the inclined air distribution plate 27 are welded to the inner ring of the furnace through steel plates; the horizontal width of the horizontal air distribution plate 28 is recorded as W1; the horizontal projection width of the inc...

Embodiment 2

[0068] The present invention also provides a circulating fluidized bed boiler, which includes: the air distribution device that facilitates the discharge of large particles in the first embodiment, the feed pipe 1 and the furnace wall 6.

[0069] The furnace wall 6 is a fire-resistant, wear-resistant and heat-preserving furnace wall. The surrounding interior is a furnace. The inclined air distribution plate 27 and the horizontal air distribution plate 28 in the air distribution device that facilitate the discharge of large particles are arranged in the middle of the furnace, and the horizontal air distribution is A number of second air hoods 26 are arranged staggered on the plate 28, with independent air chambers for air supply; on the inclined air distribution plate 27, a number of first air hoods 25 are arranged in line, and an independent air chamber is arranged for air supply; At the lowest point of the lower end of the inclined air distribution plate 27, there is a gate valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com