Automatic narrow-gap submerged arc welding process for all-welded fixed ball valve with medium and large calibers

A fixed ball valve, submerged arc welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of valve product scrap, valve scrap, affecting weld strength, etc., to achieve reasonable production process flow, convenient slag discharge And the effect of exhaust, easy exhaust and slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

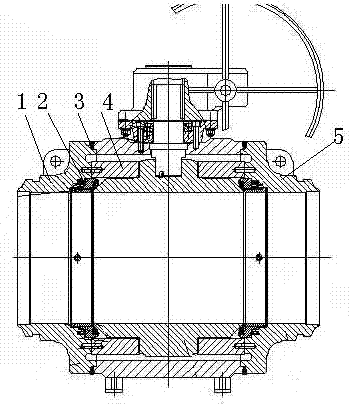

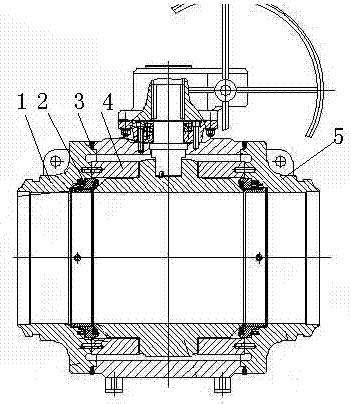

[0024] 1) Product assembly, the sealing ring 2 is installed on both sides of the ball valve body 4, and is respectively assembled and matched with the left valve body 1 and the right valve body 5 for final assembly and clamping;

[0025] 2) Prepare before welding, use automatic submerged arc welding machine, DC ammeter and voltmeter, grind and clean the 20-22mm edge of the weldment until the metal is smooth, and remove spot welding slag;

[0026] 3) Material selection, choose welding wire grade H08MnA and flux grade HJ431, wire diameter selection Φ1.6mm welding wire, welding flux storage temperature is 5 ℃, relative humidity 20%; welding working environment relative humidity 20%, flux at 350 ℃ Dry it under the oven, keep it warm for 2 hours, and use it immediately after drying. The position of the welding wire is 5 mm above the vertical centerline of the valve body;

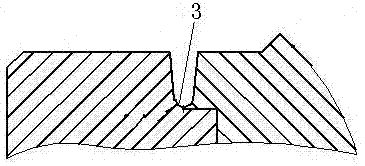

[0027] 4) Weld seam selection, the weld used for welding adopts "U"-shaped groove 3, the root of "U"-shaped gr...

Embodiment 2

[0031] 1) Product assembly, the sealing ring 2 is installed on both sides of the ball valve body 4, and is respectively assembled and matched with the left valve body 1 and the right valve body 5 for final assembly and clamping;

[0032] 2) Prepare before welding, use automatic submerged arc welding machine, DC ammeter and voltmeter, grind and clean the 22mm edge of the weldment until the metal is smooth, and remove spot welding slag;

[0033] 3) Material selection, choose welding wire grade H08MnA and flux grade HJ431, wire diameter selection Φ1.8mm welding wire, welding material flux storage temperature is 45 ℃, relative humidity 60%; welding working environment relative humidity 90%, flux at 400 ℃ Dry it under the oven, keep it warm for 2.5 hours, and use it immediately after drying. The position of the welding wire is 6 mm above the vertical centerline of the valve body;

[0034] 4) Weld seam selection, the weld used for welding adopts "U"-shaped groove 3, the root of "U"-...

Embodiment 3

[0038] 1) Product assembly, the sealing ring 2 is installed on both sides of the ball valve body 4, and is respectively assembled and matched with the left valve body 1 and the right valve body 5 for final assembly and clamping;

[0039] 2) Prepare before welding, use automatic submerged arc welding machine, DC ammeter and voltmeter, grind and clean the 20-22mm edge of the weldment until the metal is smooth, and remove spot welding slag;

[0040] 3) Material selection, choose welding wire grade H08MnA and flux grade HJ431, wire diameter selection Φ1.7mm welding wire, welding flux storage temperature is 40 ℃, relative humidity 50%; welding working environment relative humidity 30%, flux at 380 ℃ Dry it under the oven, keep it warm for 2 hours, and use it immediately after drying. The position of the welding wire is 5 mm above the vertical centerline of the valve body;

[0041] 4) Weld seam selection, the weld used for welding adopts "U"-shaped groove 3, the root of "U"-shaped g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com