Method of improving yield of continuous casting molten steel

A yield and molten steel technology, applied in casting equipment, casting melt containers, mechanical cleaning, etc., can solve problems such as increasing the difficulty of operation, and achieve the effect of improving the yield of molten steel and facilitating slag discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment takes Q235B steel as an example, and its main chemical composition range is: C: 0.15% to 0.19%, Si: 0.07% to 0.17, Mn: 0.20% to 0.35%, P<0.025%, S<0.025%, The rest is Fe and unavoidable impurities.

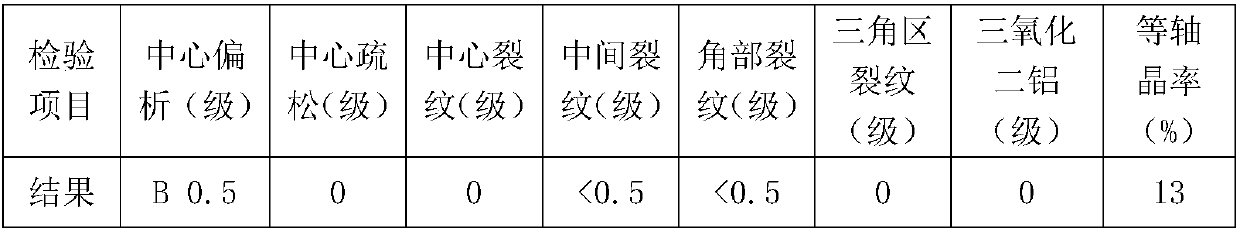

[0029] Continuously cast 14 bags of molten steel with large ladles according to the method of the present invention. When casting the 7th bag and the 13th bag, the liquid level of the tundish is raised twice for slagging, and the 13th bag of molten steel is cast before slagging. The billets were sampled, the inspection results are shown in Table 1, and the effect verification is shown in Table 2;

[0030] The chemical composition (%) of cast steel of table 1 embodiment 1

[0031] C

Embodiment 2

[0032] Table 2 embodiment 2 effect verification

[0033]

[0034] [Example 2]

[0035] A method for improving the yield rate of continuous casting molten steel, the specific steps are as follows:

[0036] This embodiment takes Q235B steel as an example, and its main chemical composition range is: C: 0.15% to 0.19%, Si: 0.07% to 0.17, Mn: 0.20% to 0.35%, P<0.025%, S<0.025%, The rest is Fe and unavoidable impurities.

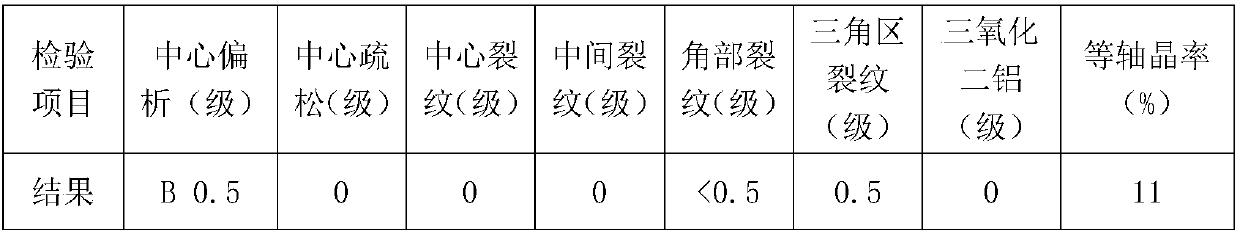

[0037] Continuously cast 14 bags of molten steel with large ladles according to the method of the present invention, when casting the 5th bag, the 9th bag, and the 13th bag, raise the liquid level of the tundish for three times and carry out slagging, and cast the 9th bag of molten steel Sampling of the slab before slag discharge, the inspection results are shown in Table 3, and the effect verification is shown in Table 4;

[0038] The chemical composition (%) of cast steel of table 3 embodiment 2

[0039] C

Si

mn

P

S

0.17

0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com