Preconditioning process of continuous wall for weak weathering terrane grooving construction

A trough-forming construction and micro-weathering technology, which is applied to sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of delay in construction period, easy-to-damage impact hammers, stuck hammers, etc., increase costs, facilitate slag discharge, and improve construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

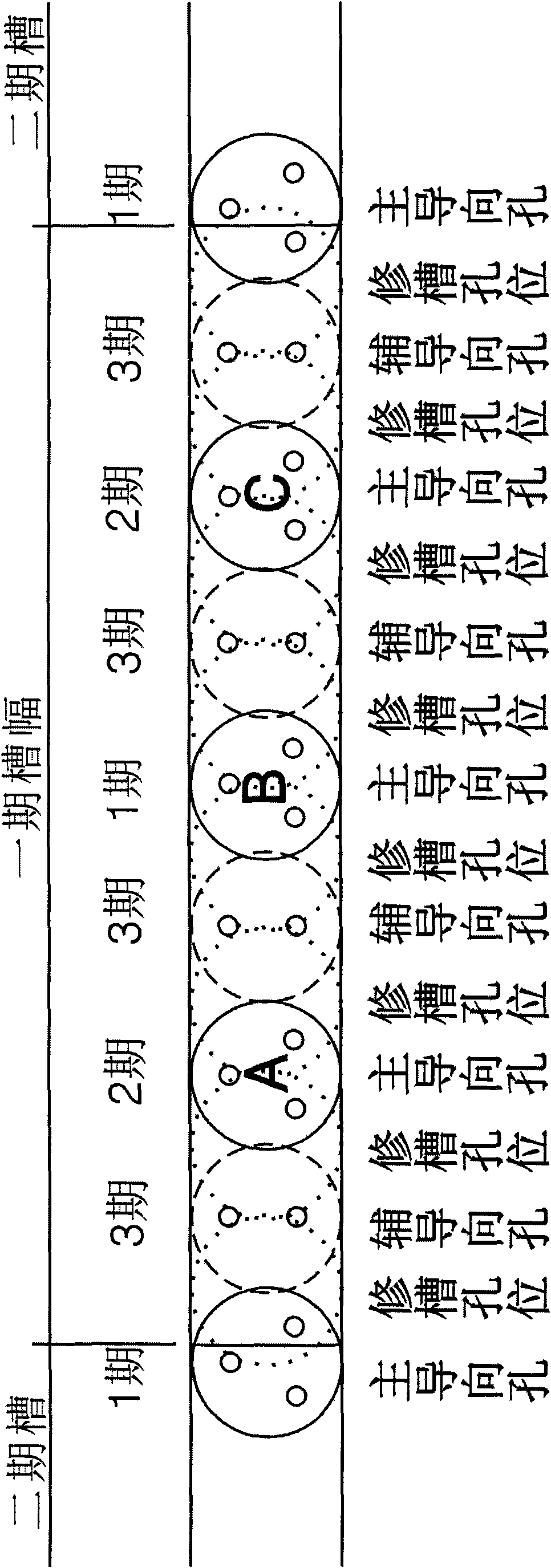

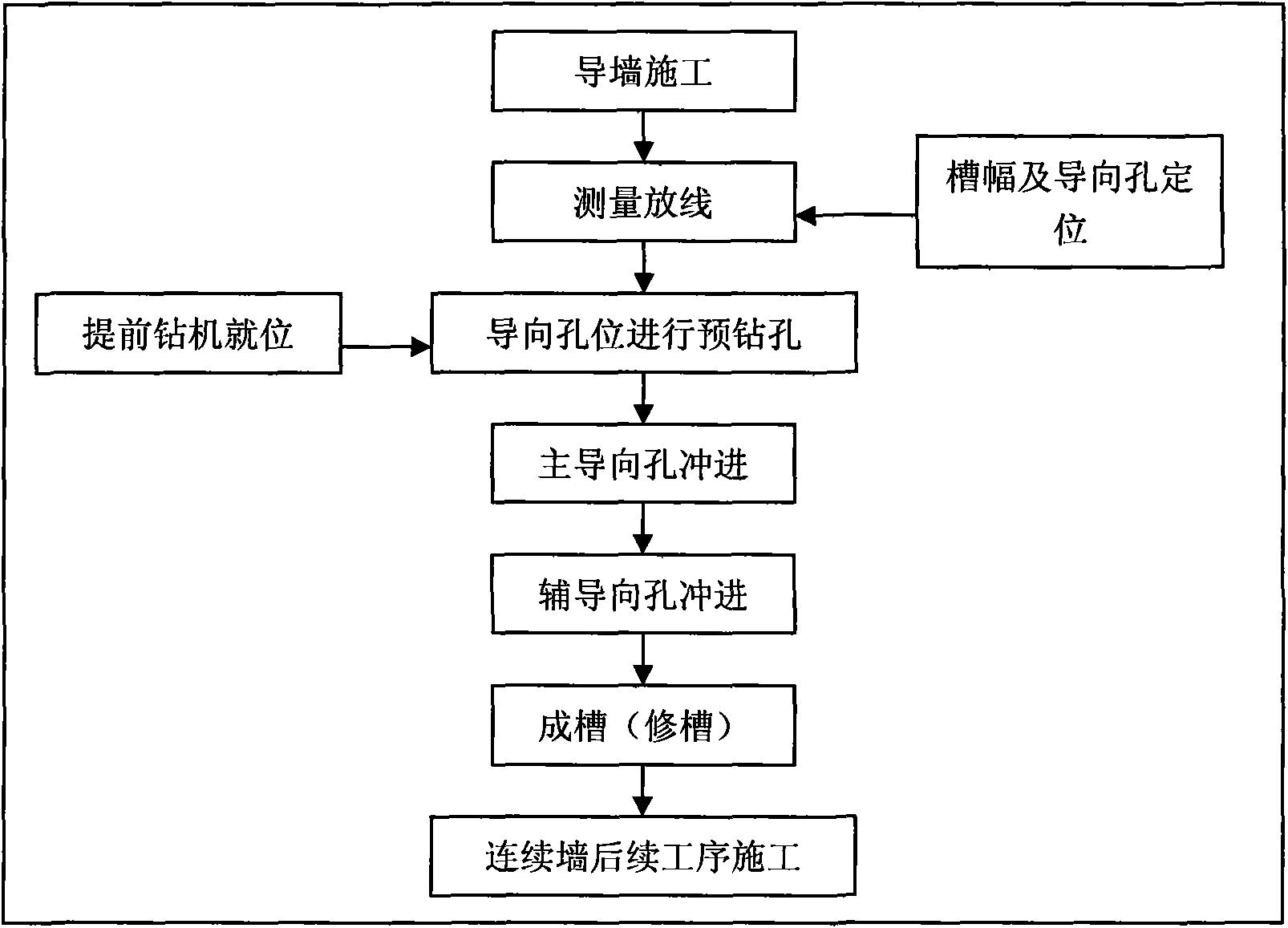

[0017] Such as figure 2 As shown, the implementation steps of the pretreatment process of the diaphragm wall in the groove construction of the micro-weathered rock formation are:

[0018] First, make the following construction preparations:

[0019] 1. Before the pre-drilling construction of the diaphragm wall, the geological conditions of the project should be understood in detail, a special construction plan should be prepared, and the process design should be carried out according to the selected construction machine.

[0020] 2. Clean up the construction platform, remove ground obstacles, and determine the working surface according to the required location of mechanical equipment.

[0021] 3. Measure and locate, determine the center line according to the design pile position, make a mark, and determine the pretreatment hole positions of the main guide hole and the auxiliary guide hole according to the position of the pile center line.

[0022] 2. Drilling rig

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com